Magnesium hydroxide-calcium alginate composite flame retardant and preparation method thereof

A technology of compound flame retardant and calcium alginate, which is applied in fire-resistant coatings and other directions, can solve the problems of unsatisfactory thermal decomposition temperature of products, cumbersome and complicated process, limiting flame retardant effect, etc., and achieves green environmental protection materials and simple process. , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The concrete steps of preparation are:

[0030] In step 1, the dolomite ore powder is calcined at 900° C. for 3 hours; wherein, the particle size of the dolomite ore powder is 0.1 mm to obtain dolomite lime powder. Then, according to the solid-to-liquid ratio of 1g:5ml, dolomite lime powder was added to water at 20°C and stirred for 60 minutes to obtain digestive juice.

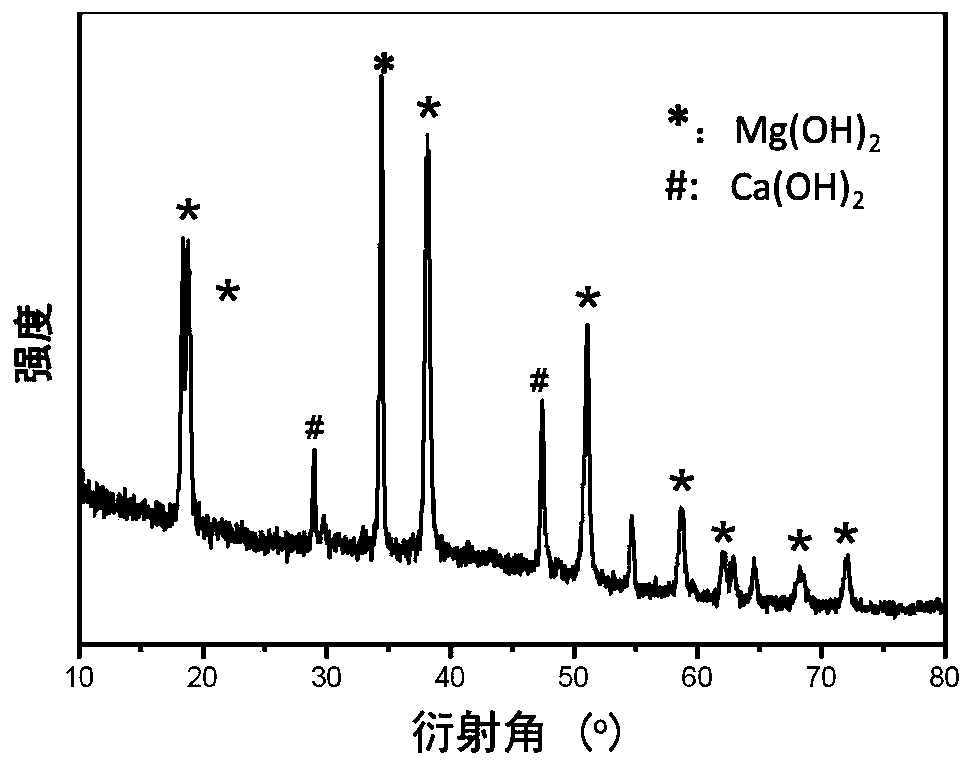

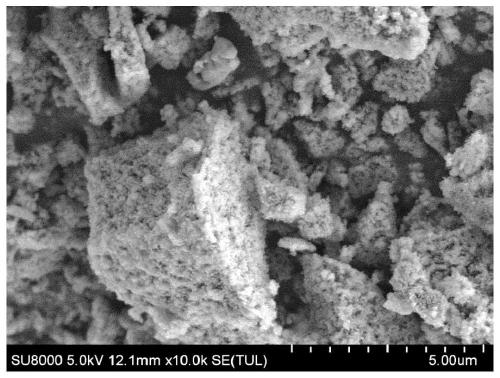

[0031] Step 2: First, according to the volume ratio of 1wt% sodium alginate aqueous solution and digestive juice at a ratio of 1:5, add sodium alginate aqueous solution dropwise to the digestive juice under stirring at 20°C, and stir and foam for 10 minutes to obtain foam bubble gel. The foamed gel is then subjected to drying and setting treatment; wherein, the drying and setting treatment is mold forming drying and setting treatment, and the temperature during the drying and setting treatment is 40° C. made as figure 1 As shown in the curves in , and approximated by figure 2 The magnesium hydroxi...

Embodiment 2

[0033] The concrete steps of preparation are:

[0034] In step 1, the dolomite ore powder is calcined at 925° C. for 2.5 hours; wherein, the particle size of the dolomite ore powder is 1 mm to obtain dolomite lime powder. Then, according to the solid-to-liquid ratio of 1 g: 17 ml, the dolomite lime powder was added into water at 38° C. and stirred for 53 minutes to obtain a digestive juice.

[0035] Step 2: First, according to the volume ratio of 3.3wt% sodium alginate aqueous solution and digestive juice at a ratio of 1:4, add sodium alginate aqueous solution dropwise to the digestive juice under stirring at 38°C, and stir and foam for 23 minutes to obtain Foaming gel. The foamed gel is then subjected to drying and setting treatment; wherein, the drying and setting treatment is mold forming and drying and setting treatment, and the temperature during the drying and setting treatment is 50° C. made as figure 1 As shown in the curves in , and approximated by figure 2 The m...

Embodiment 3

[0037] The concrete steps of preparation are:

[0038] In step 1, the dolomite ore powder is calcined at 950° C. for 2 hours; wherein, the particle size of the dolomite ore powder is 4 mm to obtain dolomite lime powder. Then according to the solid-to-liquid ratio of 1g:28ml, dolomite lime powder was added to water at 56°C and stirred for 45 minutes to obtain digestive juice.

[0039] Step 2: First, according to the volume ratio of 5.5wt% sodium alginate aqueous solution and digestive juice at a ratio of 1:3, add sodium alginate aqueous solution dropwise to the digestive juice under stirring at 56°C, and stir and foam for 35 minutes to obtain Foaming gel. The foamed gel is then subjected to drying and setting treatment; wherein, the drying and setting treatment is mold forming and drying and setting treatment, and the temperature during the drying and setting treatment is 60° C. made as figure 1 As shown in the curves in , and as figure 2 The magnesium hydroxide-calcium al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com