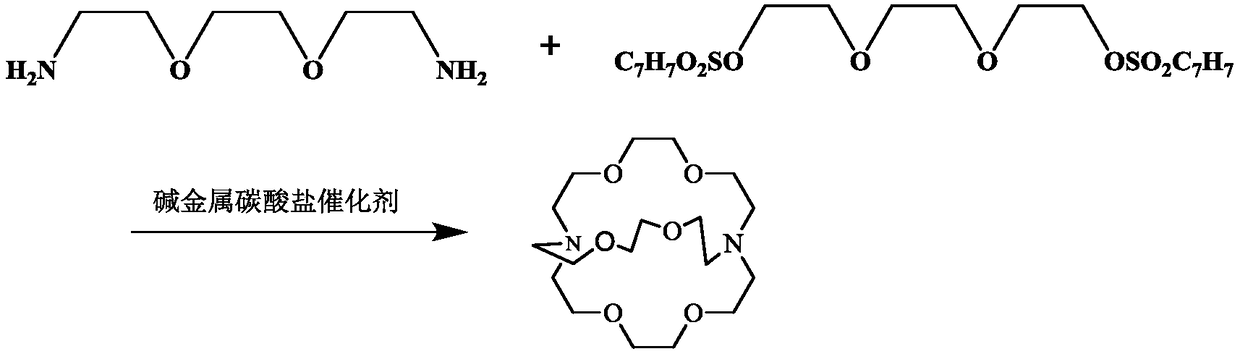

Preparation method of amino polyether (2.2.2)

An amino polyether and intermediate technology, applied in the field of preparation of amino polyether, can solve the problems of low reaction yield, long synthesis period, low yield and the like, and achieve the effect of improving the reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The present embodiment provides a kind of preparation method of amino polyether (2.2.2), comprises the steps:

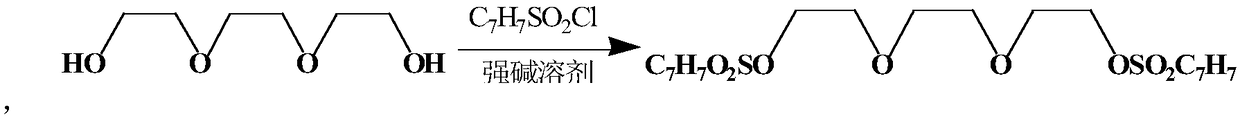

[0028] Step 1: Preparation of intermediate triethylene glycol bis(p-toluenesulfonate)

[0029] First, dissolve 0.45mol triethylene glycol in 200mL tetrahydrofuran, then add it to 250mL 5mol / L NaOH solution to form a mixed solution, place the mixed solution in ice water, control its temperature below 5°C, and start magnetic stirring.

[0030] Then, dissolve 1.08mol of p-toluenesulfonyl chloride in 200mL of tetrahydrofuran, and add it dropwise to the mixed solution for 1 hour. During the dropping process, the temperature is controlled below 5°C. After the dropping, stir the reaction 2h, the reaction temperature was controlled at 0-5°C.

[0031] Finally, after the reaction, the product was poured into a 500mL beaker of ice-water mixture, cooled, crystals were precipitated, filtered, washed with water, and dried to obtain a crude product; the crude product was re...

Embodiment 2

[0040] The present embodiment provides a kind of preparation method of amino polyether (2.2.2), comprises the steps:

[0041] Step 1: Preparation of intermediate triethylene glycol bis(p-toluenesulfonate)

[0042] First, dissolve 0.45mol triethylene glycol in 200mL tetrahydrofuran, then add it to 200mL 6mol / L NaOH solution to form a mixed solution, place the mixed solution in ice water, control its temperature below 3°C, and start magnetic stirring.

[0043] Then, dissolve 1.08mol of p-toluenesulfonyl chloride in 200mL of tetrahydrofuran, and add it dropwise to the mixed solution for 1.5 hours. During the dropping process, the temperature is controlled below 3°C. The reaction was carried out for 2.5 hours, and the reaction temperature was controlled at 0-3°C.

[0044] Finally, after the reaction, the product was poured into a 520mL beaker of ice-water mixture, cooled, crystals were precipitated, filtered, washed with water, and dried to obtain a crude product; the crude product...

Embodiment 3

[0051] The present embodiment provides a kind of preparation method of amino polyether (2.2.2), comprises the steps:

[0052] Step 1: Preparation of intermediate triethylene glycol bis(p-toluenesulfonate)

[0053] First, dissolve 0.45mol triethylene glycol in 200mL tetrahydrofuran, then add it to 250mL 4mol / L NaOH solution to form a mixed solution, place the mixed solution in ice water, control its temperature below 5°C, and start magnetic stirring.

[0054] Then, dissolve 0.99mol of p-toluenesulfonyl chloride in 500mL of tetrahydrofuran, and add it dropwise to the mixed solution. The dropping time is 3 hours. During the dropping process, the temperature is controlled below 5°C. After the dropping, stir the reaction 3.5h, the reaction temperature is controlled at 0-5°C.

[0055] Finally, after the reaction, the product was poured into a 650mL beaker of ice-water mixture, cooled, crystals were precipitated, filtered, washed with water, and dried to obtain a crude product; the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com