Online offset correction method and device for robot hand-eye calibration

A hand-eye calibration and robot technology, which is applied to manipulators, program-controlled manipulators, manufacturing tools, etc., can solve the problems of base coordinate system deflection, hand-eye calibration offset, and reduce the robot's hand-eye calibration accuracy, and achieve high calibration accuracy and precise grasping. The effect of fast operation and calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

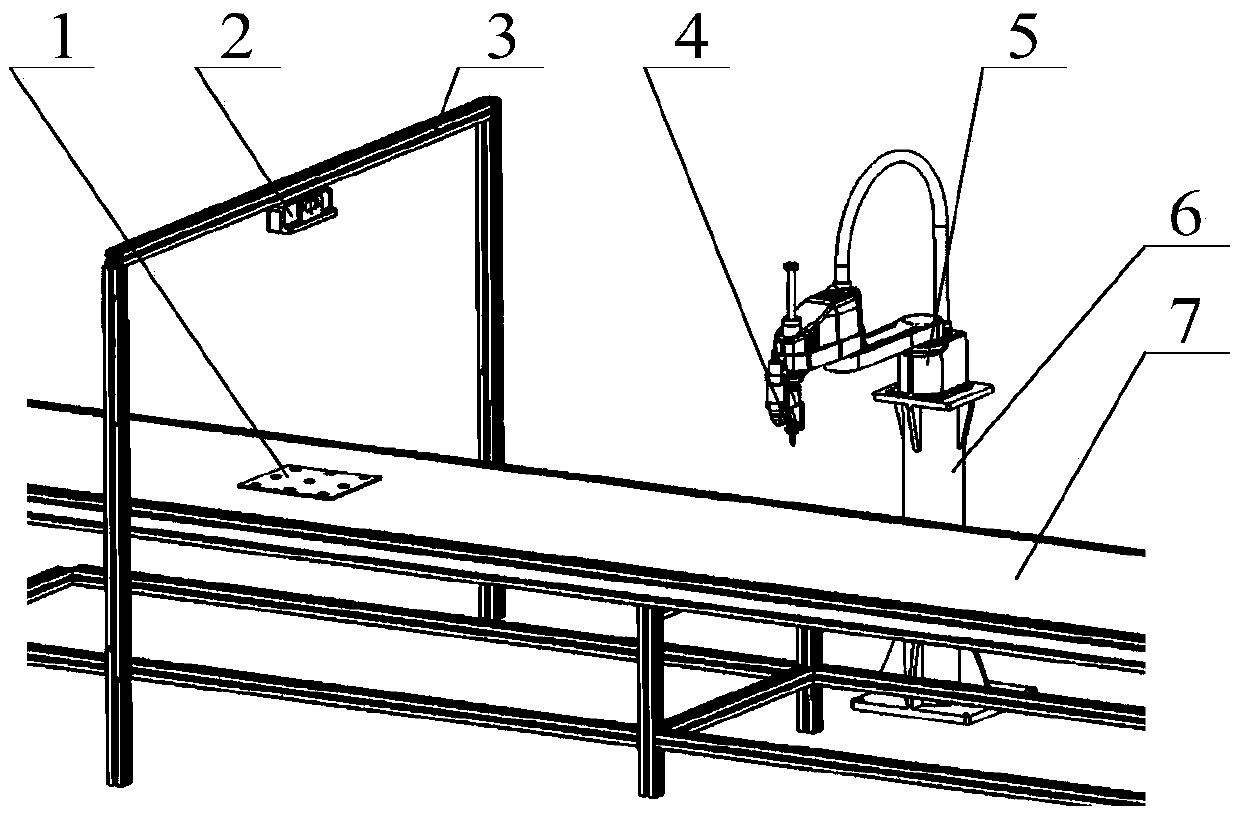

[0033] The principles and features of the present invention will be described below with reference to the accompanying drawings. The examples cited are only used to explain the present invention, and are not used to limit the scope of the present invention.

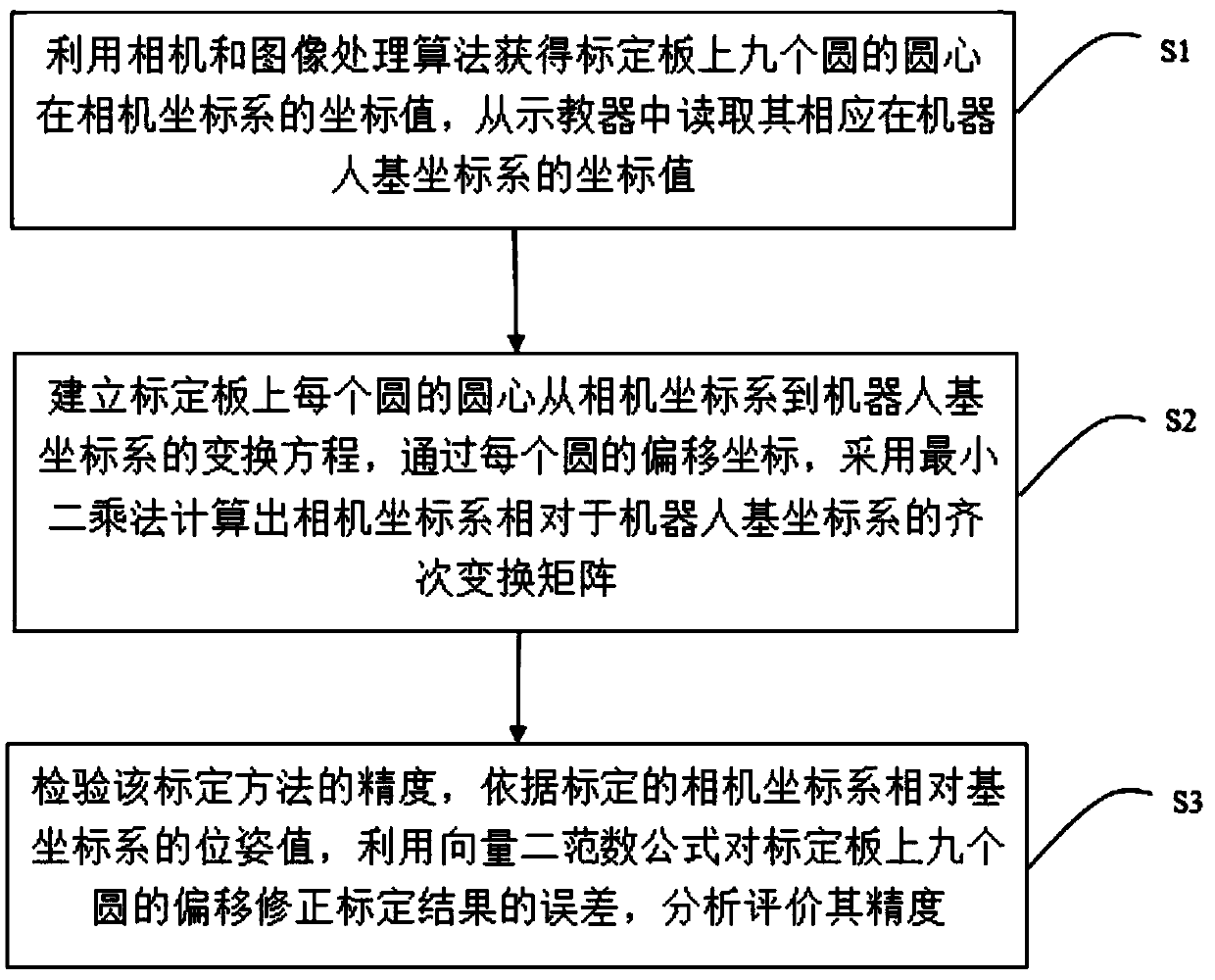

[0034] Such as figure 1 As shown, an online offset correction method for robot hand-eye calibration includes three stages: data acquisition, offset correction, and accuracy verification. details as follows:

[0035] S1: In the data acquisition stage, acquire the coordinate values of the center of the nine circles on the calibration board in the camera coordinate system and the base coordinate system, use the camera and image processing algorithms to obtain the coordinate values in the camera coordinate system, and read it from the teach pendant It corresponds to the coordinate value in the robot base coordinate system.

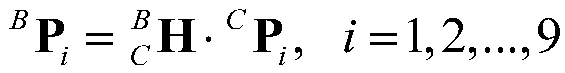

[0036] S2: Offset correction stage, establish the transformation equation of the center of each circle o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com