Punching and tapping machine

A technology of tapping machine and rotary table

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

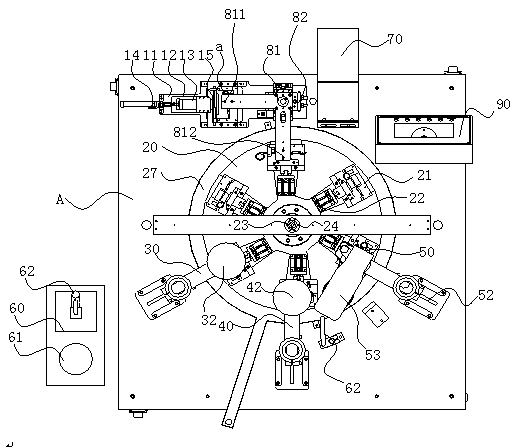

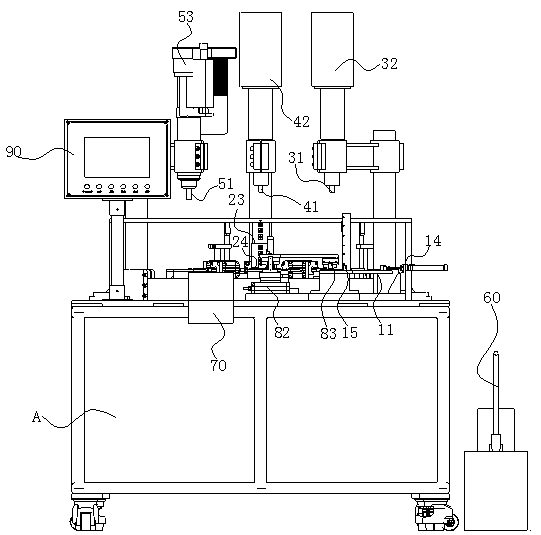

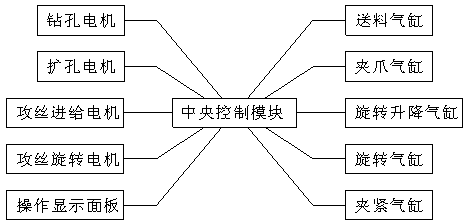

[0038] see Figure 1-2 As shown, a preferred embodiment of the present invention discloses a punching and tapping machine, comprising:

[0039] The feeding mechanism 10, the feeding mechanism 10 is used to transport the workpiece a to the feed end 811, the feeding mechanism 10 includes a feeding platform 11 arranged on an operation box cabinet A, and a loading platform fixed on the feeding platform 11 Horizontal track 12, the feed push plate 13 that is slidably connected with the horizontal track 12, the feed cylinder 14 that promotes the feed push plate 13 to translate along the horizontal track 12 and the clip-type charging box 15 that is located at the end of the horizontal track 12, the feed push The plate pushes the workpiece a in the clip-type charging box 15 to the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com