Tooth-shaped multi-pole-point transom-connecting projection welding method for cable ladder

A cable ladder frame and multi-pole technology, which is applied in the field of resistance convex welding, can solve problems such as unstable quality, large deformation, and large energy consumption, and achieve the effects of reducing production costs, improving product quality, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

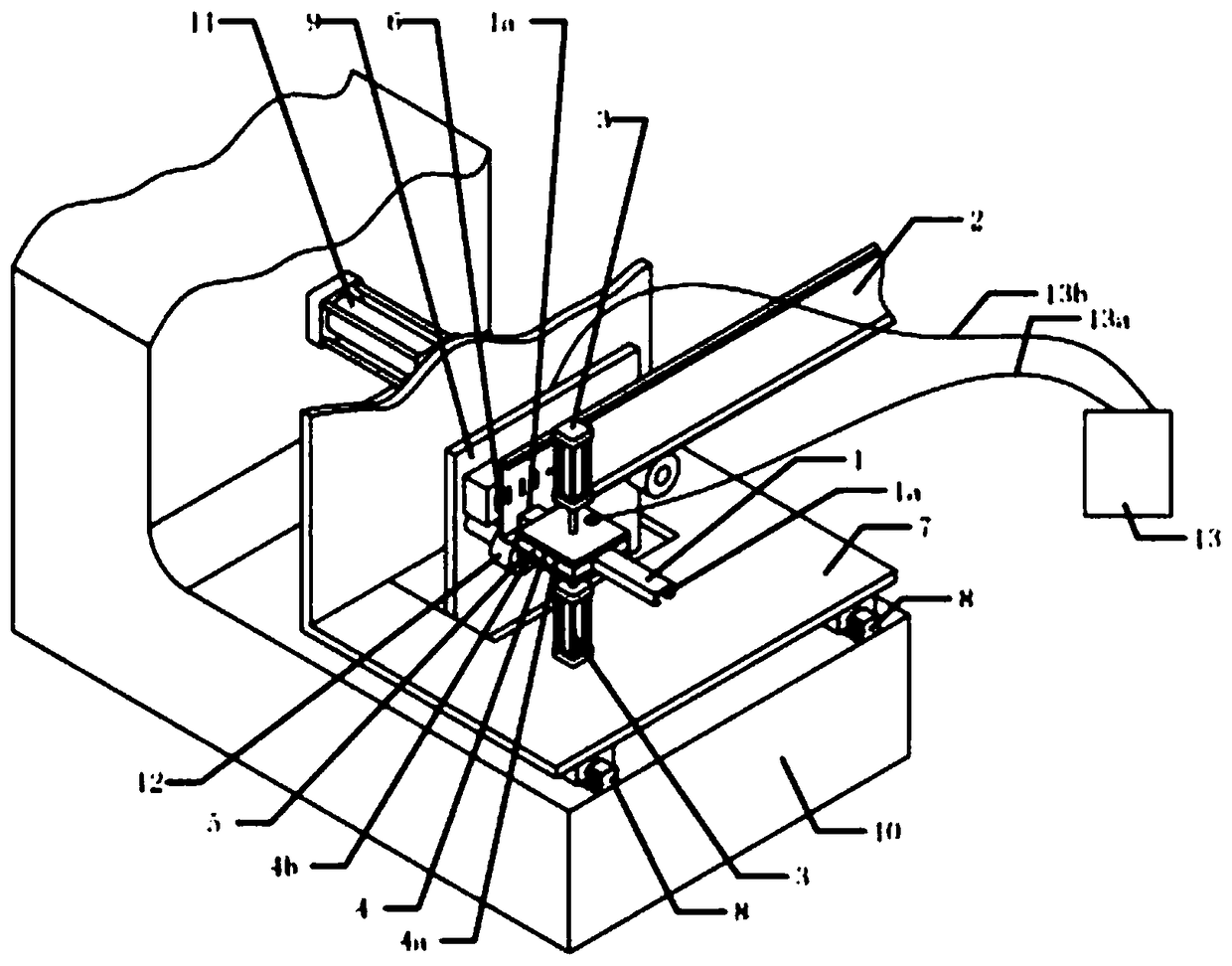

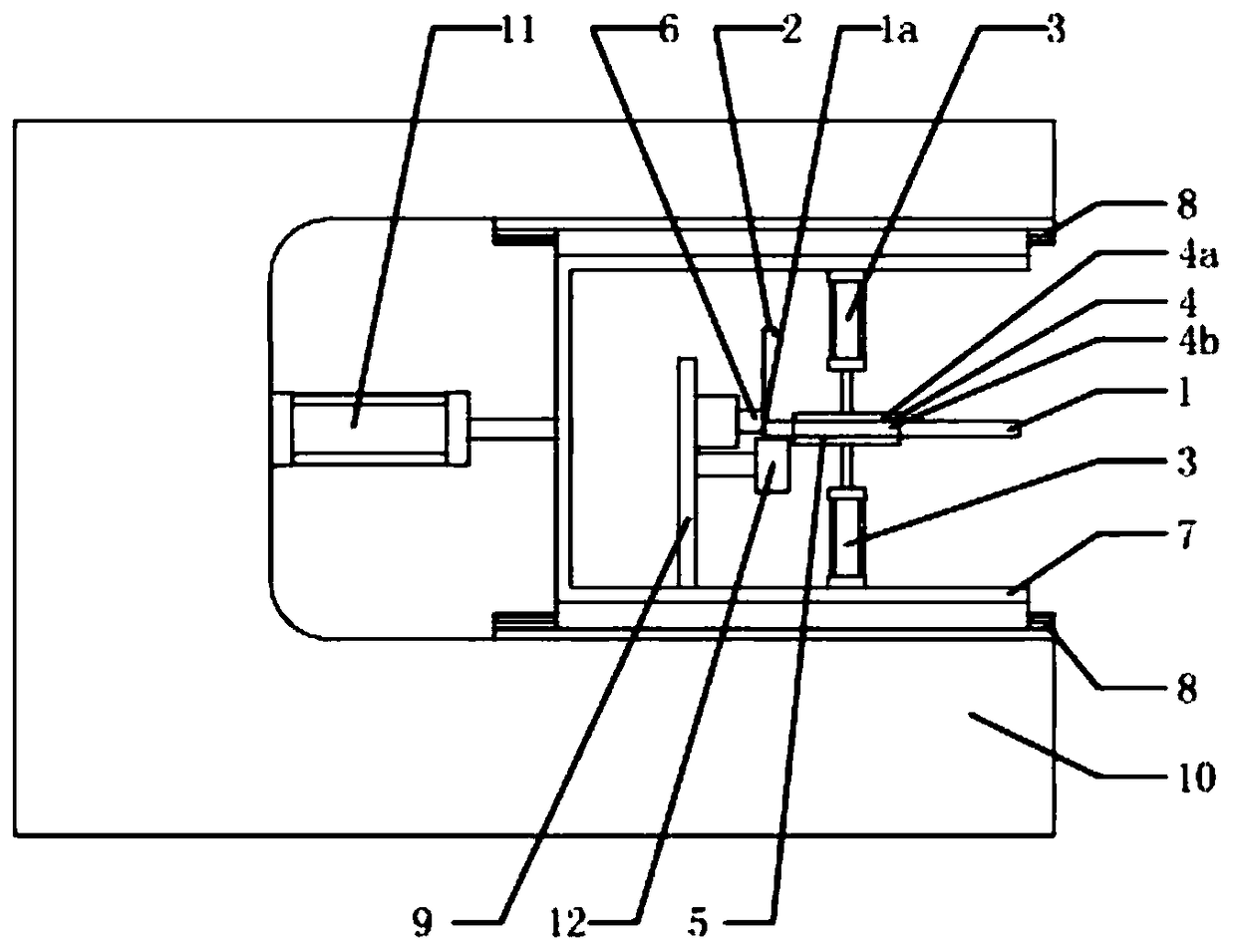

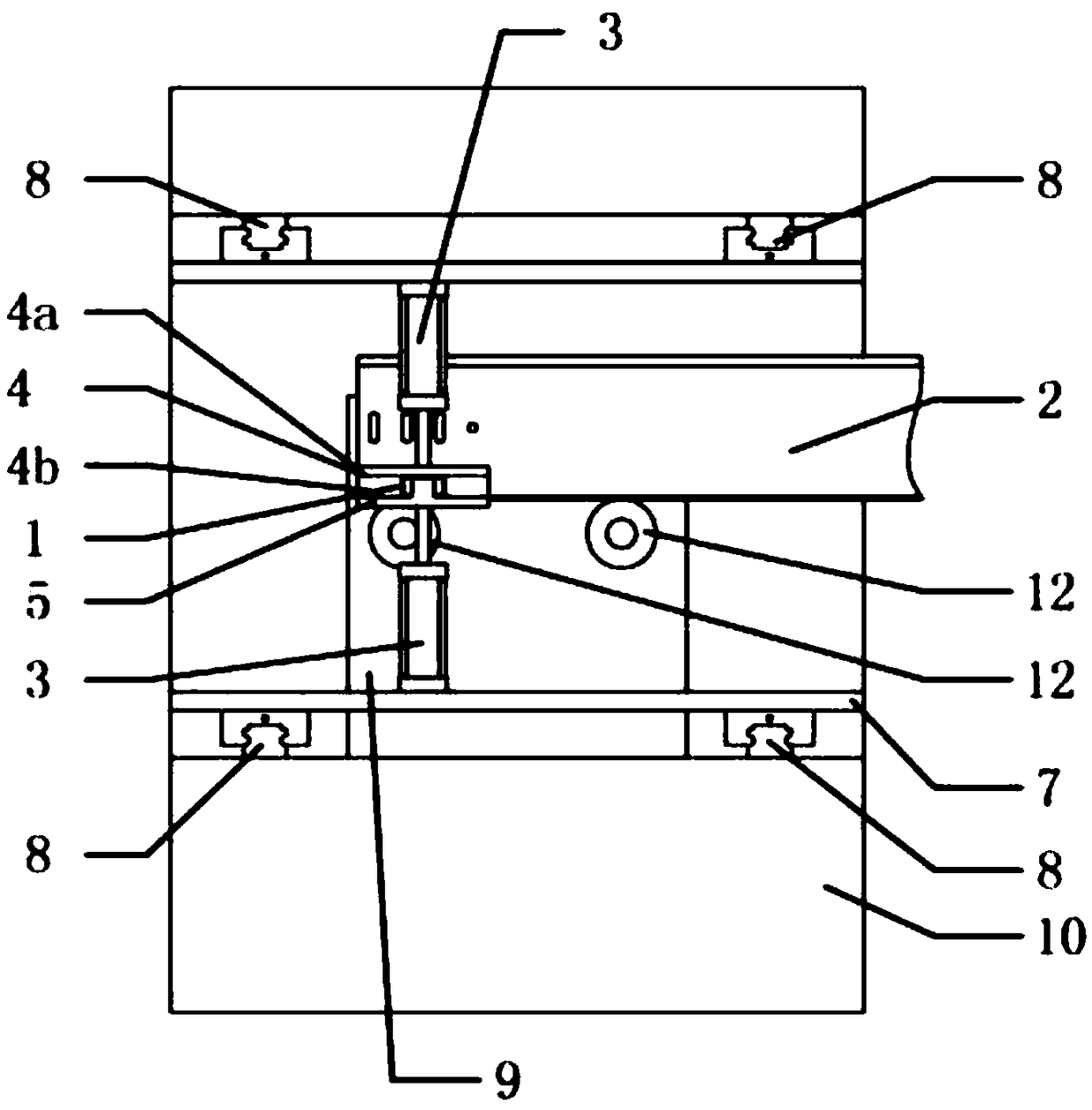

[0024] A toothed multi-pole rung connection projection welding method for a cable ladder frame of the present invention is to make the end of the workpiece where the end face is connected into a tooth shape, and the size, shape and quantity of the tooth shape are set according to the needs of the product. When welding, the tooth shape of the workpiece end is used as a bump, and the workpiece with bumps is clamped up and down by the fixture, and the flat workpiece is aligned with the bump workpiece and fixed and clamped by the fixture. The fixtures of the two parts of the workpiece are equipped with conductive blocks. The welding workpiece connected by the block and the crosspiece is closely fitted to form the current channel required for welding; multiple welding stations can be set along the length of the cable ladder for simultaneous welding, and the conductive block of the plane workpiece can be set one or more according to the number of workpiece stations. A plurality of su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com