Compact type six-roller rolling mill and work method

A six-high rolling mill, compact technology, applied in the direction of metal rolling stand, metal rolling mill stand, metal rolling, etc., can solve the problem of difficult removal, oil adhesion, strong surface tension of oil film, bearing seat cannot be connected with spray Problems such as beam and oil retaining guide plate interference, etc., to achieve the effect of comprehensive functions, compact structure, and reducing residual oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

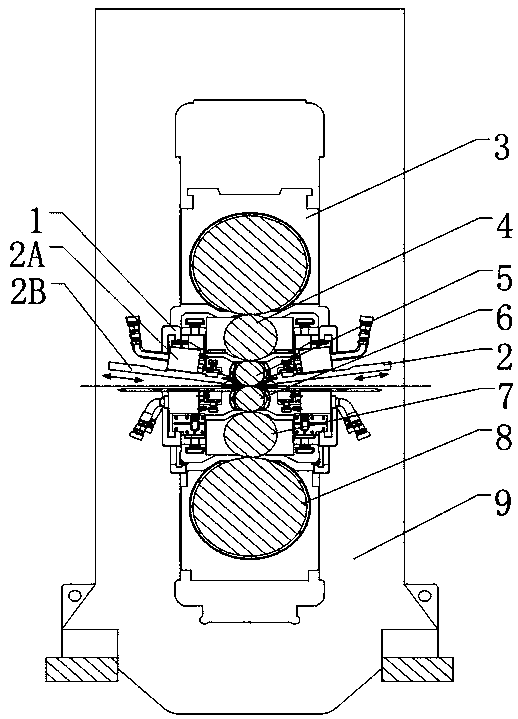

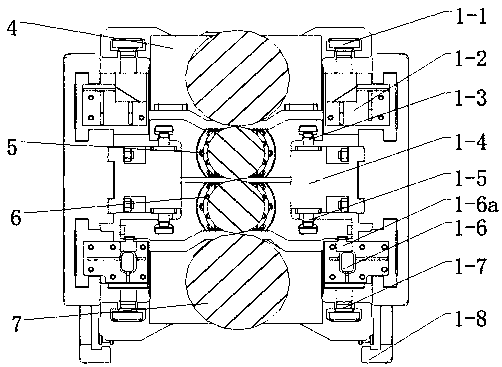

[0044] Such as figure 1 , 2 , 3, 4, 5, 6 and 7, a compact six-high rolling mill at least includes a frame 9, wherein the frame 9 includes at least a bottom fixing seat and two sets of support frames respectively fixed at the front and rear ends of the fixing seat , the two sets of supporting frames are all frame structures with the same structure, which is characterized in that: an upper support roll assembly 3, an upper intermediate roll assembly 4, an upper working roll assembly 5, a lower Work roll assembly 6, lower intermediate roll assembly 7 and lower backup roll assembly 8, in which the front and rear ends of upper backup roll assembly 3 and lower backup roll assembly 8 are respectively slidingly connected with two sets of support frames, upper work roll assembly 5 is connected with lower work roll assembly The roll assembly 6 has a symmetrical structure up and down. The upper intermediate roll assembly 4 and the lower intermediate roll assembly 7 have a vertically sym...

Embodiment 2

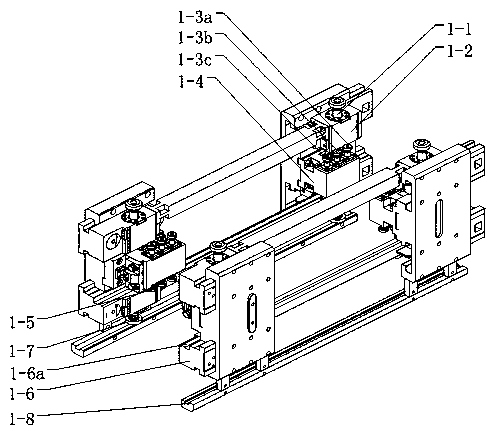

[0051] On the basis of Example 1, such as image 3 , 4 As shown in and 5, the roll bending device includes an upper intermediate roll bending cylinder block 1-2, a work roll bending cylinder block 1-4 and a lower intermediate roll bending cylinder block 1 which are sequentially fixed on the support from top to bottom -6, where the upper intermediate roll bending cylinder block 1-2 is provided with an upper intermediate roll bending cylinder piston 1-1, and the upper and lower working roll bending cylinder blocks 1-4 are respectively provided with an upper working roll bending cylinder piston 1-3 and the lower working roll bending cylinder piston 1-5, the lower middle roll bending cylinder piston 1-7 is arranged under the lower middle roll bending cylinder block 1-6; among them, the upper working roll bending cylinder piston 1-3 It consists of the first piston 1-3a, the second piston 1-3b and the third piston 1-3c arranged in a straight line from front to back. The structure o...

Embodiment 3

[0056] On the basis of embodiment 1 or 2, such as Figure 5 As shown, the upper intermediate roller piston mechanism includes an upper intermediate roller nitrogen piston 4-1 and an upper intermediate roller guide post 4-3, and the upper intermediate roller guide post 4-3 is set outside the upper intermediate roller nitrogen piston 4-1 and inside It is connected with the upper intermediate roller nitrogen piston 4-1, and the upper intermediate roller guide column 4-3 is also provided with a step;

[0057] The upper work roll piston mechanism includes an upper work roll nitrogen piston 5-2 and an upper work roll guide post 5-3, the upper work roll guide post 5-3 is set outside the upper work roll nitrogen piston 5-2 and the inner part is connected with the upper work roll Roll nitrogen piston 5-2 connection;

[0058] The lower intermediate roller piston mechanism includes a lower intermediate roller nitrogen piston 7-1 and a lower intermediate roller guide post 7-3. The nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com