Tea leaf auto-spread greening system

An automatic, tea technology, applied in the direction of tea processing before extraction, can solve the problems of enterprise production constraints, high labor costs, and large labor shortages, so as to reduce the dependence of labor, reduce the risk of production not running normally, and improve the spread of green. effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

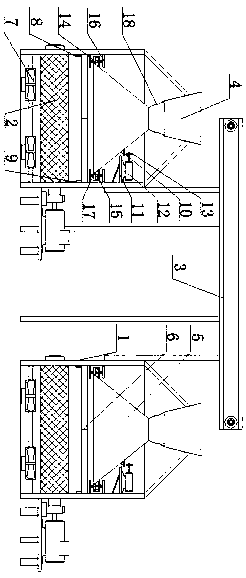

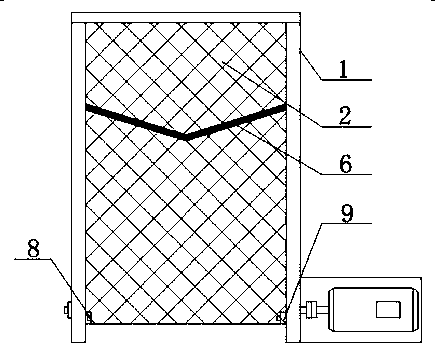

[0015] Embodiments of the present invention: a kind of automatic greening system for tea leaves, as attached Figure 1-3 As shown, there are 2 green spreading tanks 1 which are arranged symmetrically and with openings at the head ends. Metal mesh conveyor belts 2 are arranged in the green spreading tanks 1, and a Feeding conveyor belt 3, the two ends of feeding conveyor belt 3 are respectively located directly above the two stall green tanks 1, and a tea feeding hopper 4 is respectively arranged below the two ends of feeding conveyor belt 3, and the bottom of tea feeding hopper 4 is connected with tea distributor 5 The tea divider 5 includes a bottom plate 501 with a trapezoidal structure, the left and right sides of the bottom plate 501 are provided with side plates 502, the bottom and bottom ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com