Segmented anti-blocking cleaning device with variable roll angle and control method thereof

A technology of cleaning device and side inclination angle, which is used in threshing equipment, cutters, agricultural machinery and implements, etc., can solve the problems of offset accumulation and blockage of materials, save energy, improve screening efficiency, and facilitate operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

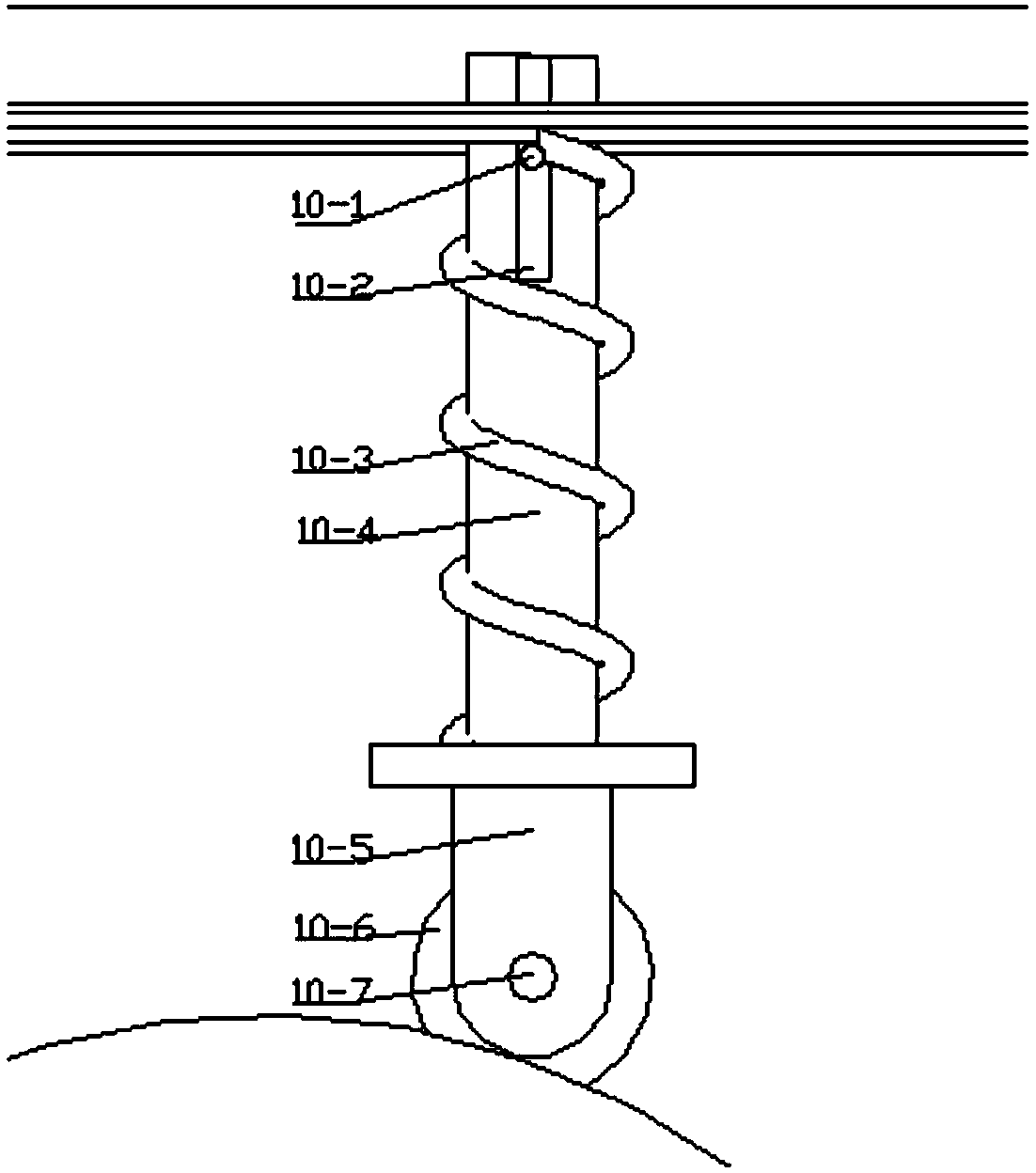

[0032] Such as figure 1 As shown, the segmented anti-blocking cleaning device with variable side inclination angle of the present invention includes a load cell 1, a left sieve plate 2, a main sieve plate 4, a motor 7, a cam 9, and a combined structure of a roller push rod 10. The right sieve plate 11 and the controller 12, the left sieve plate 2 and the right sieve plate 11 are respectively connected to the main sieve plate 4 through the connecting bushing 5, and the left sieve plate 2 and the right sieve plate The plate 11 is rotatable relative to the main screen deck 4 . Specifically, in this embodiment, the left sieve plate 2, the right sieve plate 11 and the connecting bushing 5 are fixed by interference fit and cannot be rotated relative to each other; the main sie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com