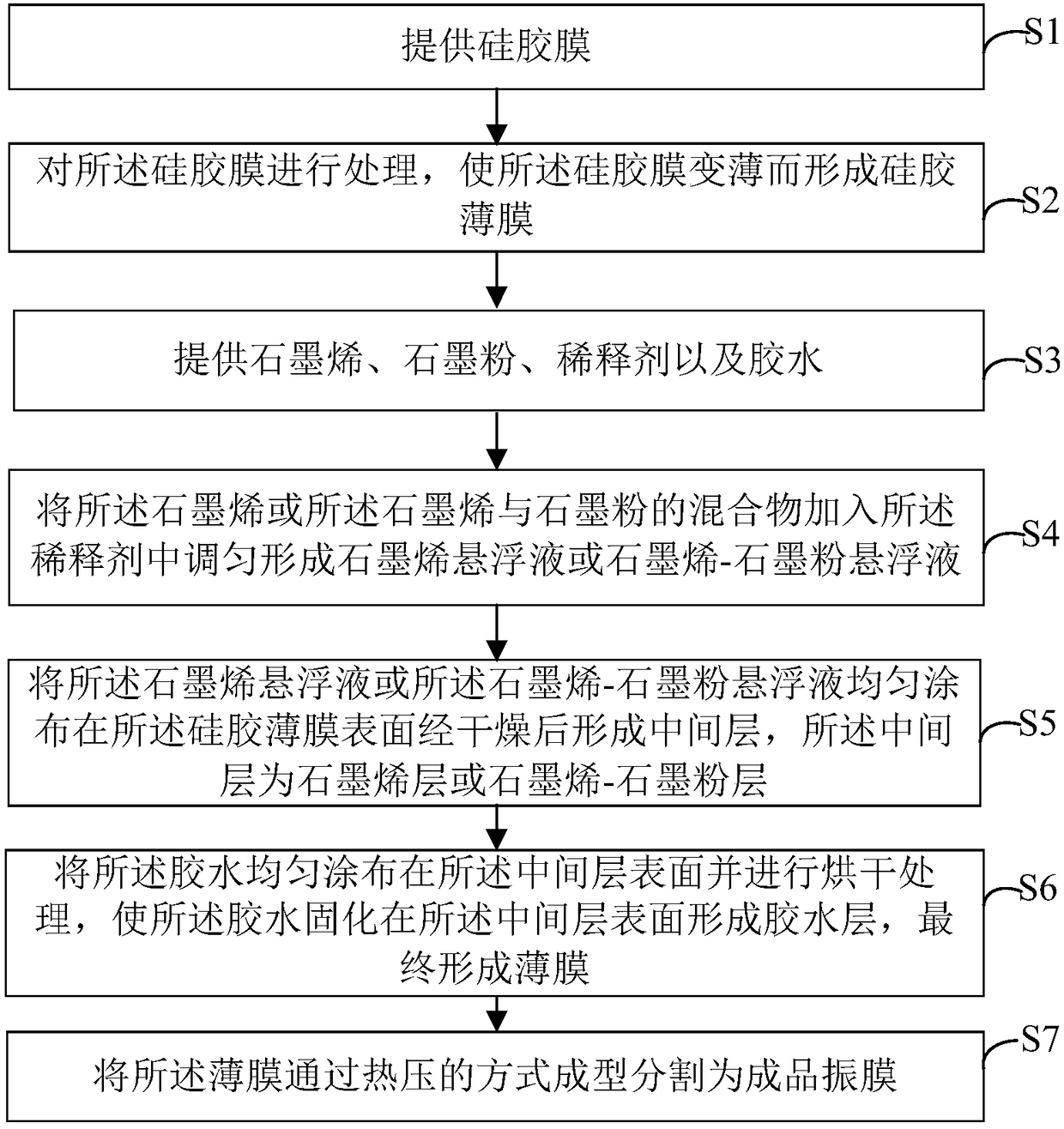

Vibrating diaphragm and manufacturing method thereof

A production method and silicone membrane technology, applied in the direction of planar diaphragm, diaphragm extension, diaphragm structure, etc., can solve the problems of poor high and low frequency performance, poor rigidity, etc., and achieve good low frequency characteristics, low resonance frequency, and better low frequency characteristics Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

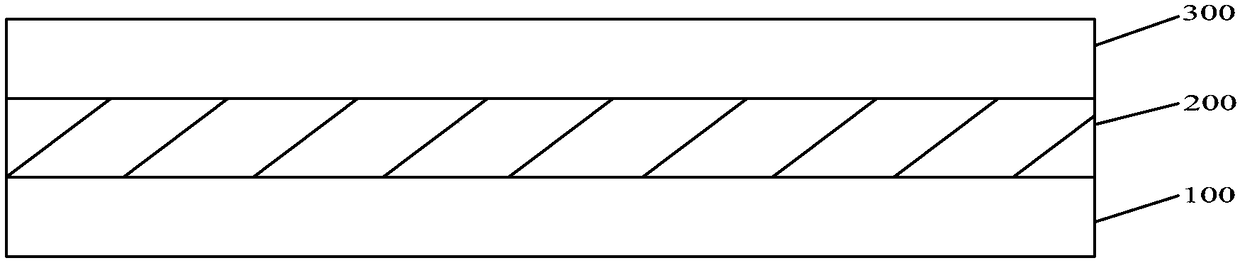

Embodiment 1

[0062] A. Graphene is mixed in the diluent, take 5g of graphene, 9995g of diluent, mix 5g of graphene in 9995g of diluent, stir evenly, make graphene evenly disperse in the diluent.

[0063] B. After the graphene is evenly dispersed in the diluent, the graphene suspension formed by it is evenly coated on the surface of the substrate layer 100 (i.e. the surface of the silica gel film) by means of slit coating or texture coating, The cloth speed is 20m / min, and the silica gel film coated with the graphene suspension is cured. The curing temperature can be set at 100°C and the curing time can be set at 2min.

Embodiment 2

[0065] A. Graphene is mixed in the diluent, take 7g of graphene, 9993g of diluent, mix 7g of graphene in 9993g of diluent, stir evenly, make graphene evenly disperse in the diluent.

[0066] B. After the graphene is evenly dispersed in the diluent, the graphene suspension formed by it is evenly coated on the surface of the substrate layer 100 (i.e. the surface of the silica gel film) by means of slit coating or texture coating, The cloth speed is 10m / min, and the silica gel film coated with the graphene suspension is cured. The curing temperature can be set at 95°C and the curing time can be set at 2min.

Embodiment 3

[0068] A. Graphene is mixed in the diluent, take 10g of graphene, 9990g of diluent, mix 10g of graphene in 9990g of diluent, stir evenly, make graphene evenly disperse in the diluent.

[0069] B. After the graphene is evenly dispersed in the diluent, the graphene suspension formed by it is evenly coated on the surface of the substrate layer 100 (i.e. the surface of the silica gel film) by means of slit coating or texture coating, The cloth speed is 15m / min, and the silica gel film that has been coated with graphene-graphite powder suspension on the surface is cured. The curing temperature can be set to 105°C, and the curing time can be set to 2min.

[0070] The middle layer 200 is made by mixing the mixture of graphene and graphite powder through diluent:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com