Preparation method of high-multiplying-power quick charging graphite cathode material and material

A graphite anode, high-rate technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of complex process and high cost, and achieve the effect of simple process flow, improved isotropy, and reduced cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: The preparation method of a kind of high-magnification fast-charging graphite negative electrode material provided by this embodiment comprises the following steps: pulverize the raw material of petroleum coke, the particle size D50 after pulverization is 3-10um, obtain artificial graphite through graphitization, graphite The melting temperature is 2200°C, and then 97% by weight of artificial graphite and 3% by weight of pitch, a carbon-containing binder, are subjected to mechanical fusion treatment. The speed of mechanical fusion is 300rpm and the time is 18min. Carbonization and sintering treatment was carried out under gas protection for 18 hours, and the carbonization temperature was 900°C. After carbonization treatment, a high-rate fast-charging graphite negative electrode material was obtained.

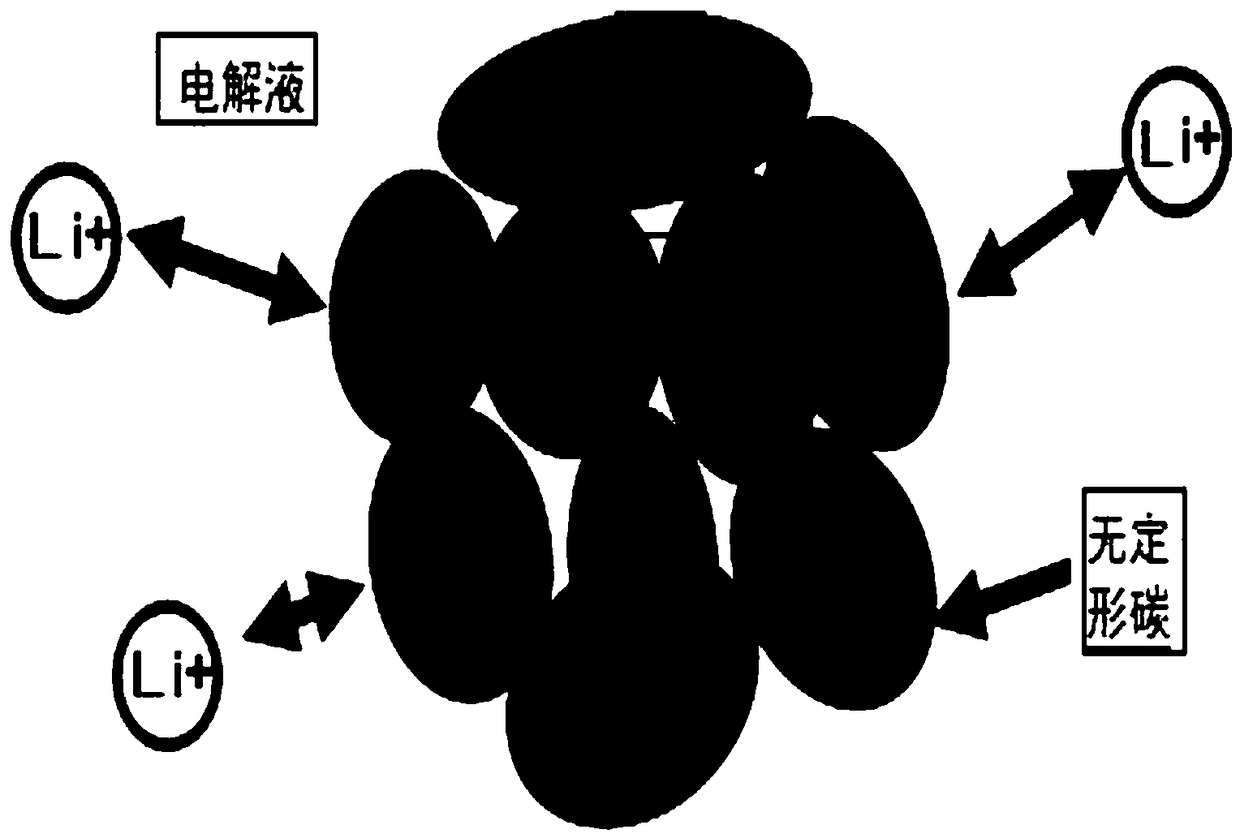

[0019] A high-rate fast-charge graphite negative-electrode material prepared by the above-mentioned high-rate fast-charge graphite negative-electrode materia...

Embodiment 2

[0020] Example 2: The preparation method of a high-rate fast-charging graphite negative electrode material provided in this example and the high-rate fast-charging graphite negative electrode material obtained by the preparation method include the following steps: pulverize the pitch coke raw material, and after pulverization The particle size D50 is 3-10um, artificial graphite is obtained through graphitization, and the graphitization temperature is 2000°C, and then 99% by weight of artificial graphite and 1% by weight of carbon source binder pitch are subjected to mechanical fusion treatment, and the mechanically fused The rotation speed is 200rpm, and the time is 25min. After that, the fused material is carbonized and sintered for 20h under the protection of an inert gas. The carbonization temperature is 1200°C. After carbonization, a high-rate fast-charging graphite negative electrode material is obtained.

Embodiment 3

[0021] Example 3: The preparation method of a high-rate fast-charging graphite negative electrode material provided in this example and the high-rate fast-charging graphite negative electrode material obtained by the preparation method include the following steps: pulverize the coal coke raw material, and after pulverization, The particle size D50 is 3-10um, artificial graphite is obtained through graphitization, and the graphitization temperature is 2400°C, and then 98% by weight of artificial graphite and 2% by weight of carbon-containing binder pitch are subjected to mechanical fusion treatment, and the mechanically fused The rotation speed is 500rpm, and the time is 5min. After that, the fused material is carbonized and sintered for 15h under the protection of an inert gas. The carbonization temperature is 1000°C. After carbonization, a high-rate fast-charging graphite negative electrode material is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com