Data cable, cable twisting machine and twisting fabrication method of data cable

A technology of data cable and stranding machine, applied in cable/conductor manufacturing, insulated cable, bendable cable, etc., can solve the problems of large material proportion, loose cable structure, large dielectric loss, etc., and achieve good equivalent dielectric Constant, reduced installation space, high electrical tensile strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The preferred embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

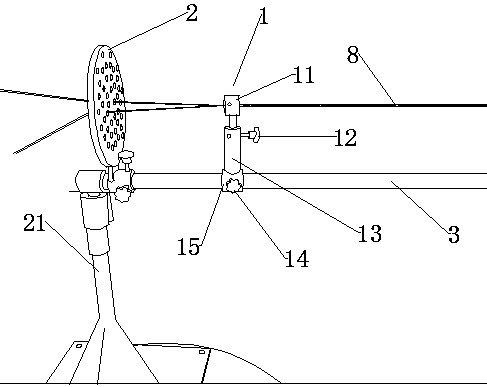

[0034] see figure 1 , figure 1 Shown is the preamble of the stranding machine of the present invention, including at least one die frame 1 and at least one distribution board 2 , both of which are mounted on horizontal support rods 3 . Wherein, the die holder 1 is composed of a die box 11, a die support column 13 and a first ferrule 15. The die is installed in a hollow position of the die box 11, and the first ferrule 15 is set on the horizontal support bar 3. On the first ferrule 15, there is an angle adjustment knob 14. On the one hand, the angle adjustment knob 14 can fix the first ferrule 15 on the horizontal support bar 3 when tightening to prevent the ferrule 15 from loosening. On the other hand, the angle adjustment knob 14 When screwing out, the first ferrule 15 is loosened so that it can freely rotate around the horiz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com