Integrated noise parameter measuring device and method

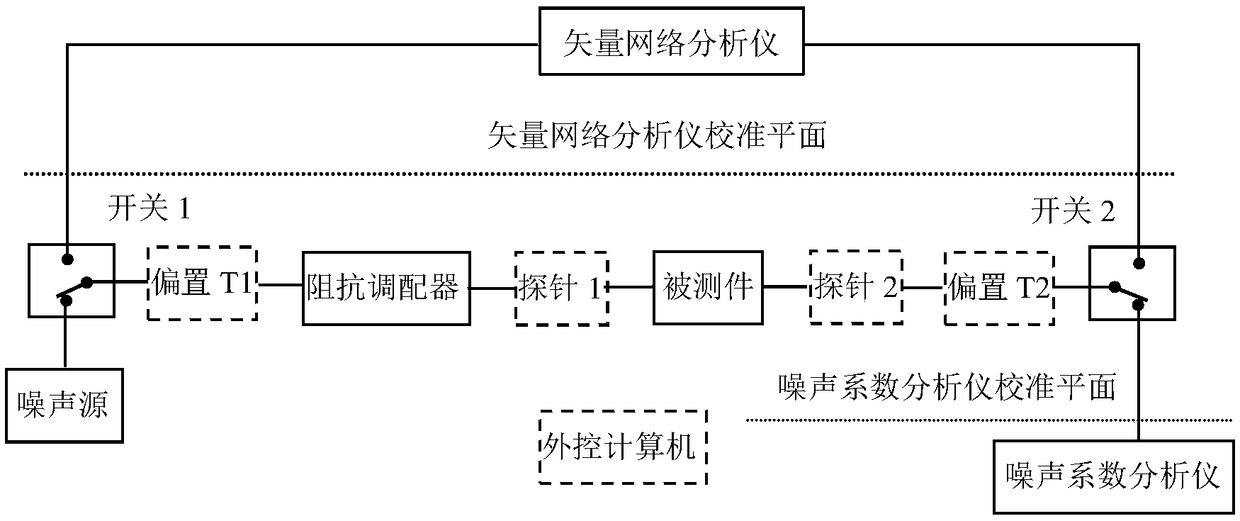

A noise parameter and parameter measurement technology, applied in the direction of noise figure or signal-to-noise ratio measurement, etc., can solve the problems affecting measurement speed, repeatability error, huge system composition, etc., and achieve good results and reasonable design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

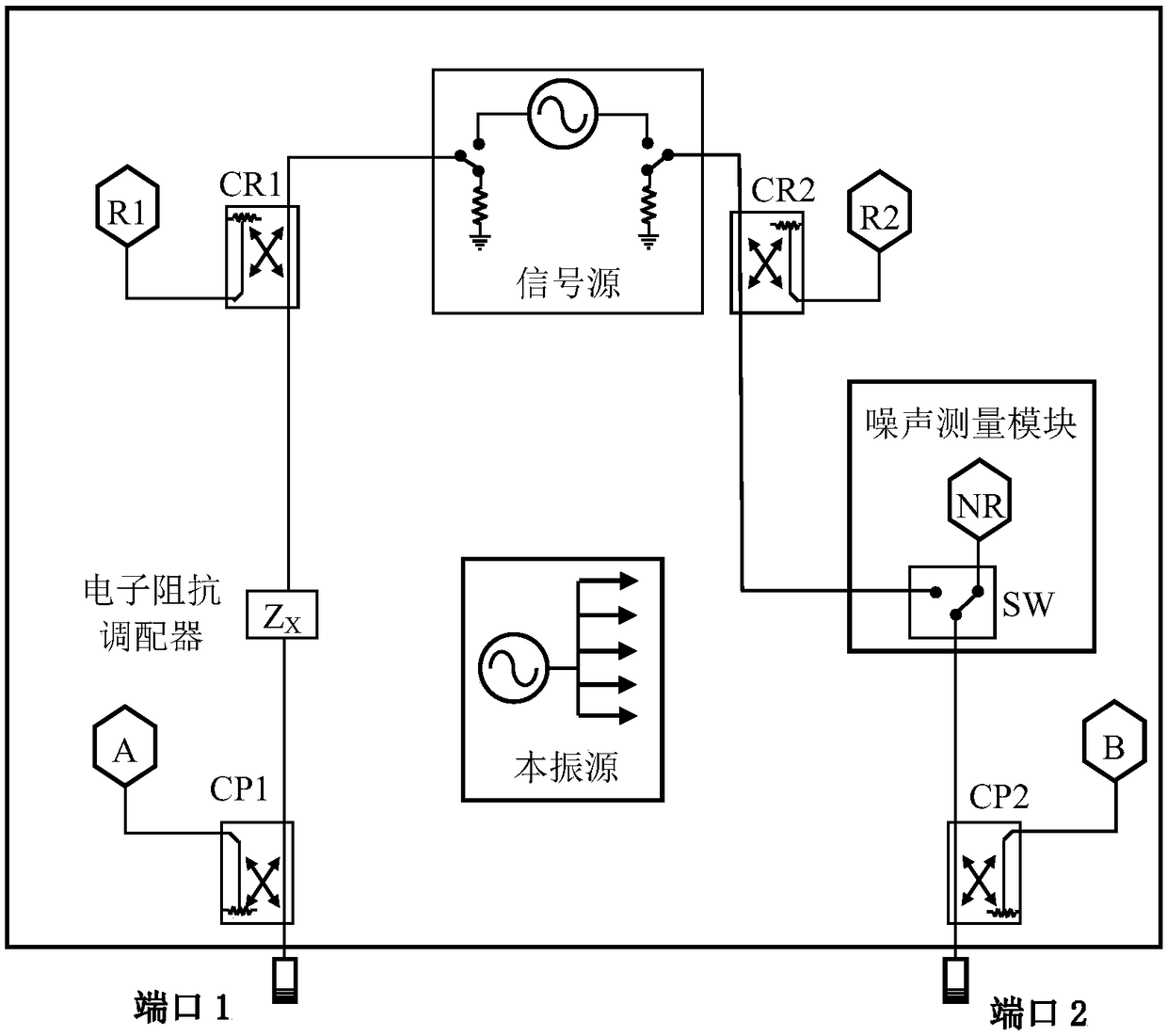

Embodiment 1

[0077] An integrated noise parameter measuring device, its structure is as follows image 3 As shown, including S parameter measurement module, electronic impedance adjuster Zx (its structure is as follows Figure 5 shown), noise measurement module and local oscillator source; S parameter measurement module, including signal source, reference coupler CR1, reference coupler CR2, reference measurement receiver R1, reference measurement receiver R2, port coupler CP1, port coupling CP2, measurement receiver A and measurement receiver B; noise measurement module, including switch circuit SW and noise power measurement circuit NR; port coupler CP1 is connected to port 1, and port coupler CP2 is connected to port 2; the definition of the coupler port is as follows Figure 4 As shown, among them,

[0078] The signal source is configured to provide a measurement excitation signal during the S-parameter measurement and calibration process, and the source signal output is turned off dur...

Embodiment 2

[0088] On the basis of the above-mentioned embodiments, the present invention also mentions an integrated noise parameter measurement method, comprising the following steps:

[0089] Step 1: S parameter calibration and pre-measurement, specifically including the following steps:

[0090] Step 1.1: The switch circuit SW in the noise measurement module is connected to the reference coupler CR2, and the electronic impedance adjuster Zx is in a straight-through state. Connect mechanical or electronic calibration components to port 1 and port 2 respectively to perform single-port reflection calibration; port 1 and Connect port 2 for straight-through calibration to solve various system errors in the S-parameter measurement process. The integrated noise parameter measurement device after S-parameter calibration can accurately measure S-parameters;

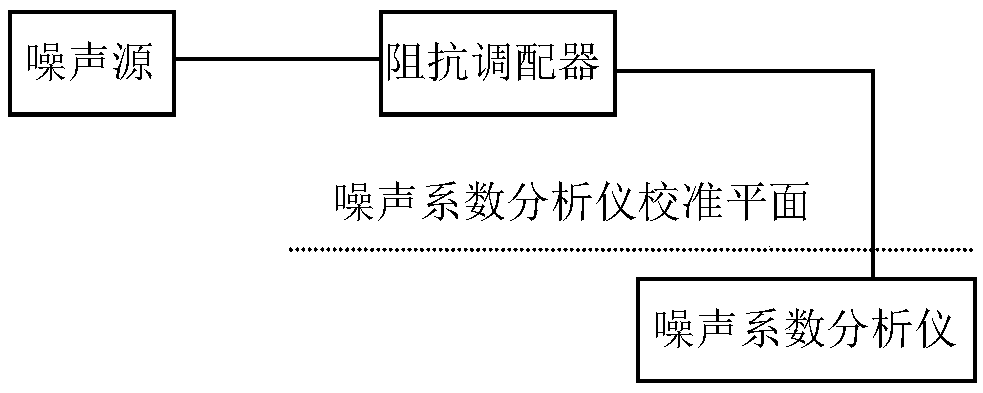

[0091] Step 1.2: Measure the reflection coefficient Γ of the noise source in the cold state and the hot state using the integrated noise...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com