a drying oven

A drying box and box technology, applied in drying chamber/container, drying solid material, drying gas layout, etc., can solve problems affecting drying quality and efficiency, inability to adapt to drying characteristics, waste of energy and resources, etc., to improve drying The quality and efficiency, the process of loading and unloading are convenient and fast, and the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

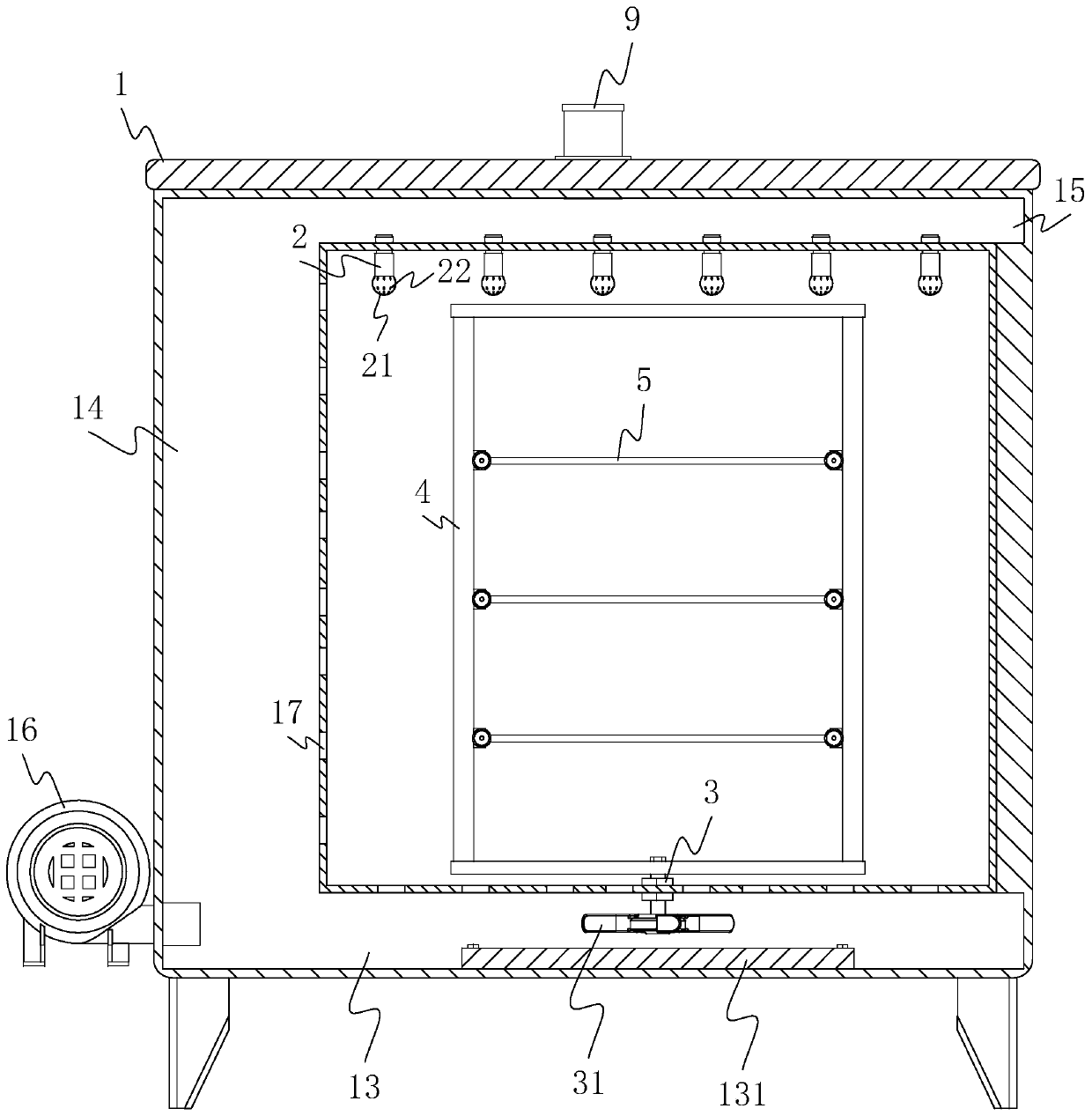

[0037] A drying oven, such as figure 1 As shown, it includes a box body 1, a box door 11 hinged at the opening of the box body 1, a window 12 is arranged on the box door 11, the material of the window 12 is borosilicate heat-resistant glass, and the upper end surface of the box body 1 is provided with a The exhaust pipe 9 inside the casing 1.

[0038] Such as figure 2 As shown, a first cavity 13 is provided inside the lower part of the box body 1, a second cavity 14 connected to the first cavity 13 is provided inside one side of the box body 1, and a second cavity 14 connected to the first cavity 13 is provided inside the box body 1, and a cavity connected to the first cavity 13 is provided inside the box body 1. The third cavity 15 of the second cavity 14 . The bottom wall of the first cavity 13 is provided with a heating plate 131, and the side wall of the box body 1 is provided with a blower 16. The air outlet of the blower 16 is connected to the second cavity 14 and is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com