Flue gas waste heat recovery and utilization combined with double bypass wide load adjustment method of air heater

A technology of load adjustment and flue gas waste heat, applied in fluid heaters, lighting and heating equipment, etc., can solve the problems of low-temperature corrosion of flue gas coolers, affecting the service life of flue gas waste heat recovery, and increasing the design area of auxiliary steam heaters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

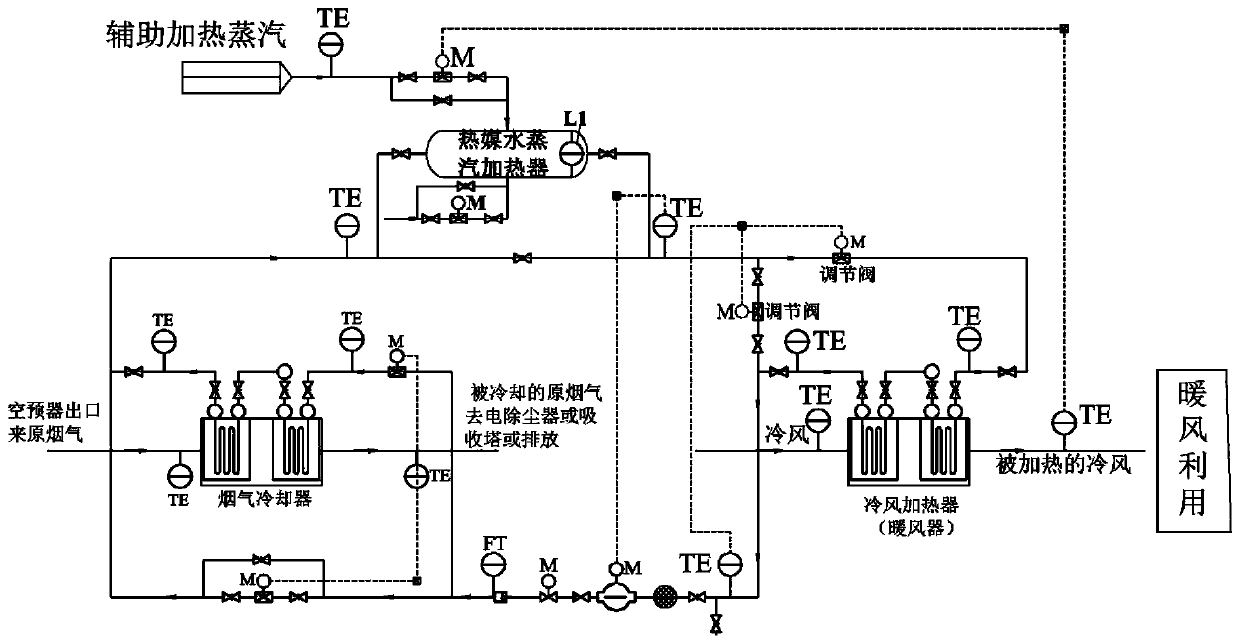

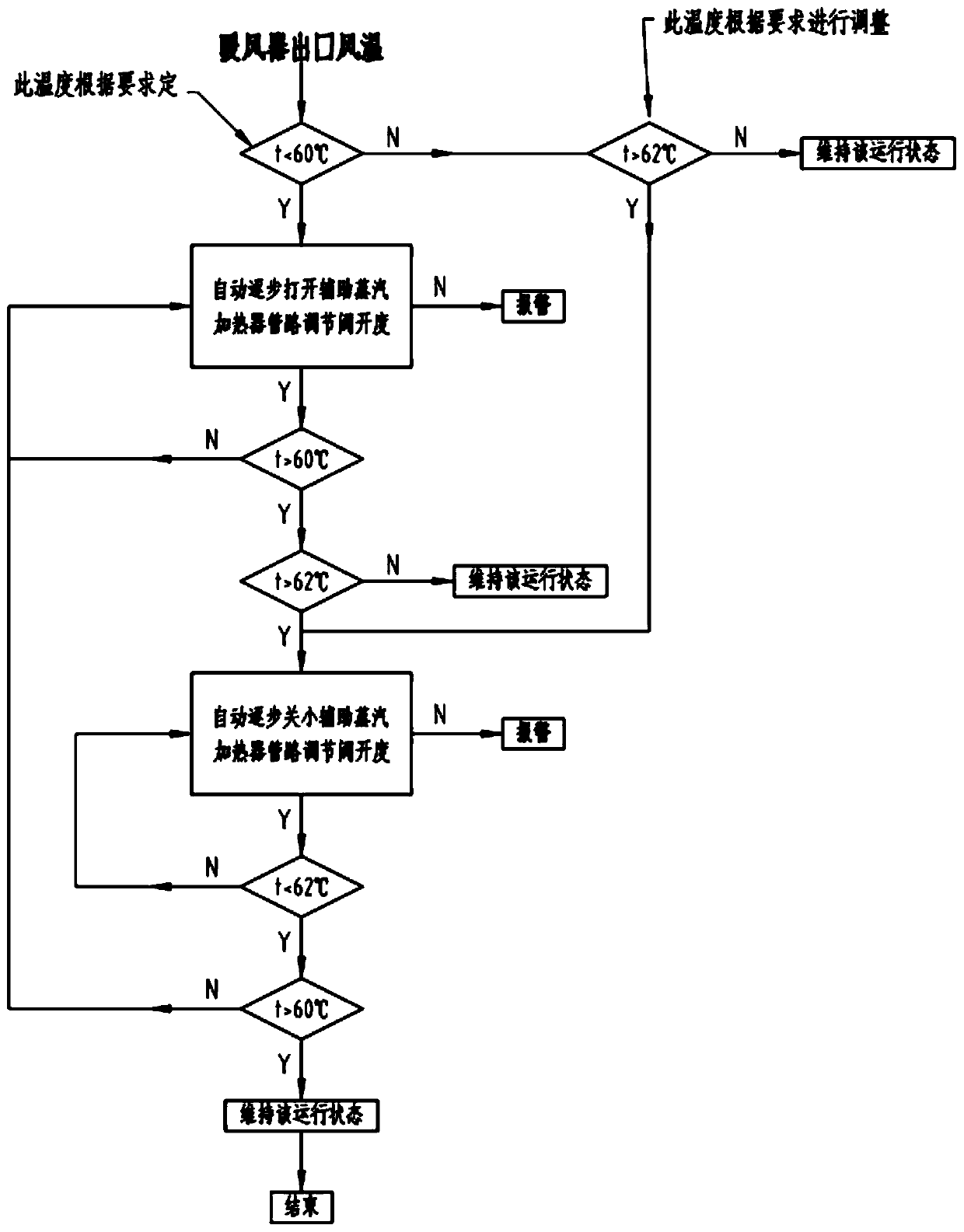

[0040] The flue gas waste heat recovery and utilization combined with the heater double bypass wide load adjustment method includes the following steps:

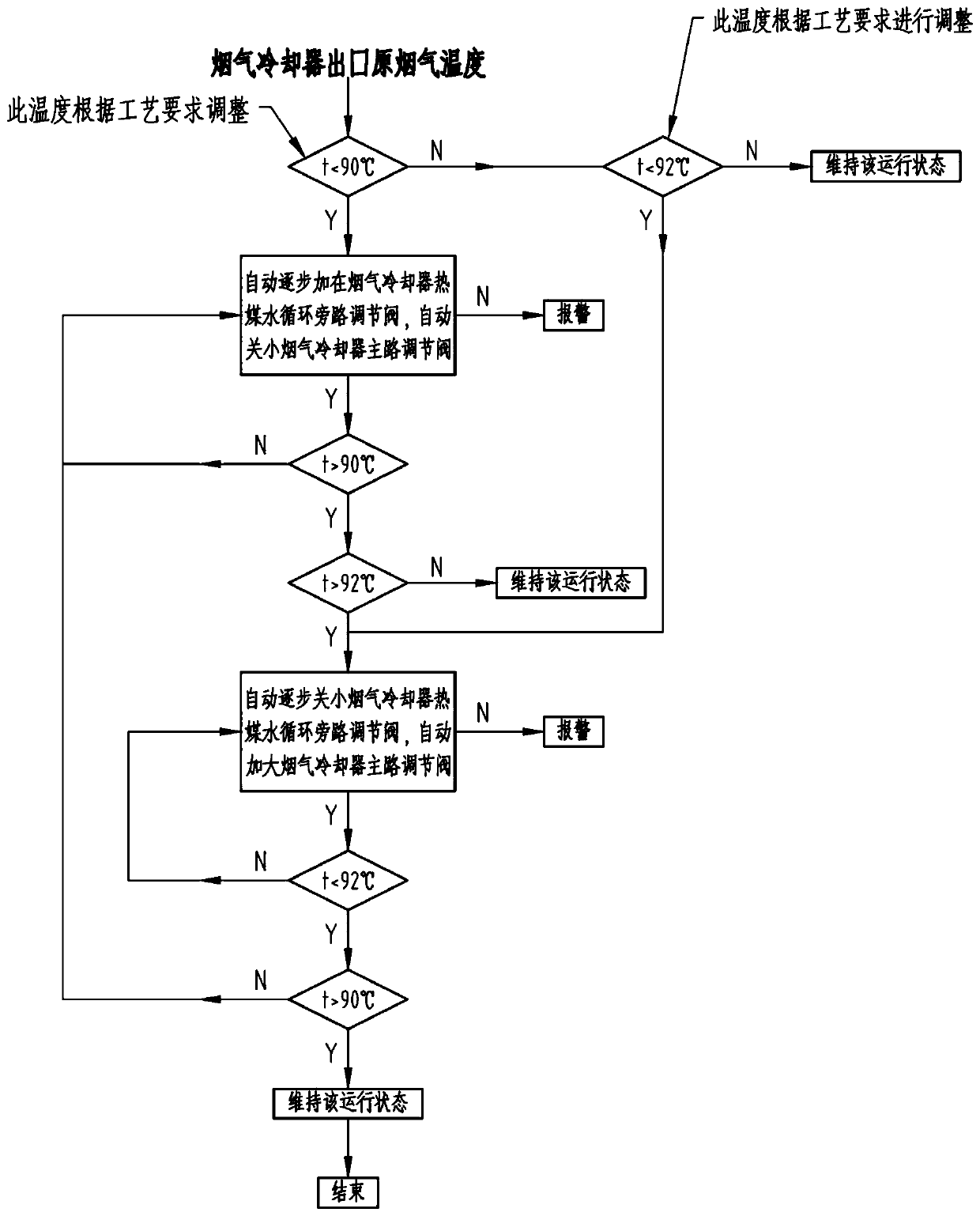

[0041] Step 1: The circulating water bypass of the flue gas cooler is to control the flue gas temperature at the outlet of the flue gas cooler. The flue gas temperature at the outlet of the flue gas cooler is controlled at the set value through the opening of the hot coal water circulation regulating valve and the main circuit regulating valve. within the scope;

[0042] Specific process such as figure 2 Shown:

[0043] S11: Collect the flue gas temperature at the outlet of the flue gas cooler in real time as the first collection temperature, and compare the first collection temperature value with the set temperature range of the first set value;

[0044] S12: If the first collection temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com