Central hot water circulation system

A circulating system, hot water technology, applied in residential hot water supply system, heating system, household heating and other directions, can solve the problems of high risk factor, unstable use, easy to produce electric shock accidents, etc., and achieve convenient use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

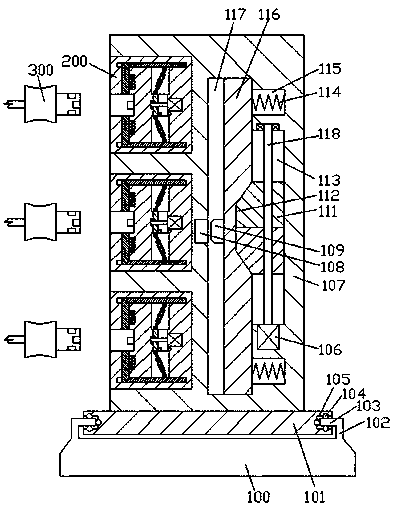

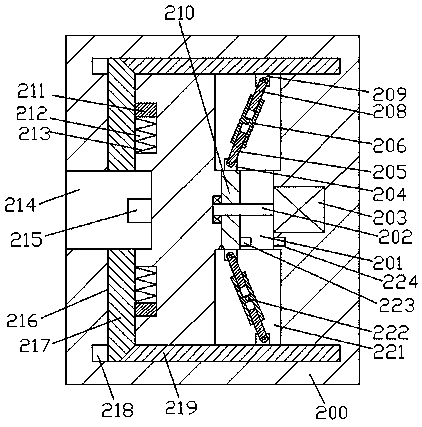

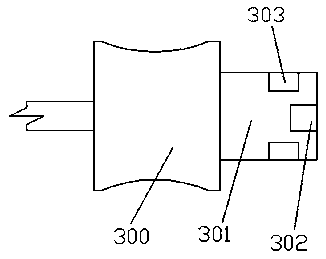

[0015] Combine below Figure 1-3 The present invention will be described in detail.

[0016] refer to Figure 1-3 , a central hot water circulation system according to an embodiment of the present invention, comprising a base frame 100, an adapter plate 101 rotatably mounted on the base frame 100, and a frame 107 fixedly installed on the adapter plate 101 And the connecting head 300 that is locked and fitly connected with the frame 107, the left end surface of the frame 107 is provided with a multi-assembly socket 200, and the left end surface of the socket 200 is provided with an insertion cavity 214, and the insertion cavity The inner wall on the right side of 214 is fixed with a first power inlet 215, and the upper and lower inner walls of the insertion cavity 214 are symmetrically provided with a first sliding connection cavity 216, and a hypotenuse locking block 217 is installed in the first sliding connection cavity 216 for sliding fit. The inner wall of the right side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com