Internal one-way valve

A one-way valve, built-in technology, applied in the direction of valve details, control valves, valve devices, etc., can solve the problems of limited size and installation position, increased cost, weight, high tolerance accuracy, etc., to reduce fluid resistance and save equipment space , the effect of improving the structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The technical solution of the present invention will be further described in detail with specific embodiments below in conjunction with the accompanying drawings. It should be understood that the following examples are only used to illustrate the present invention but not to limit the scope of the present invention.

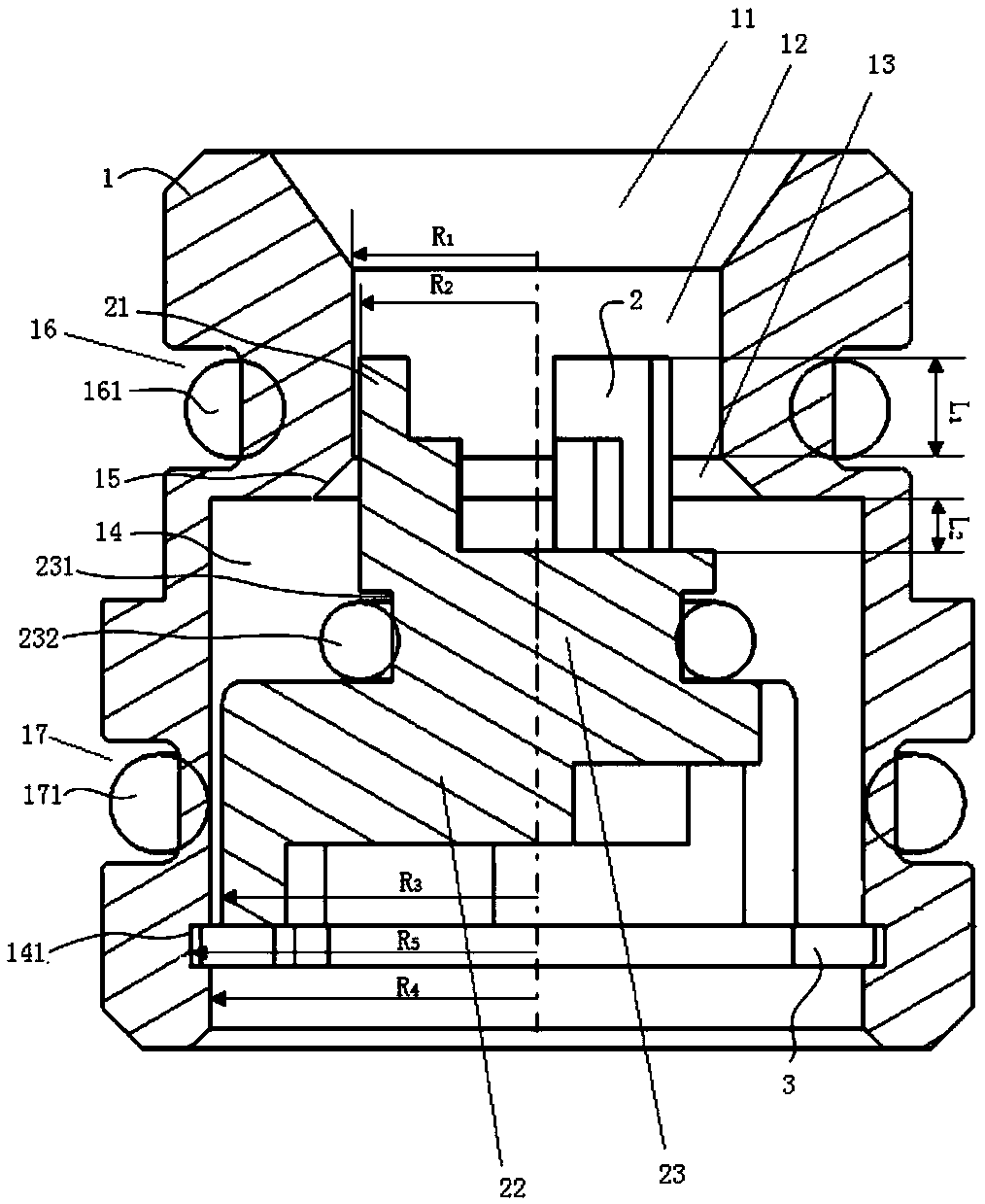

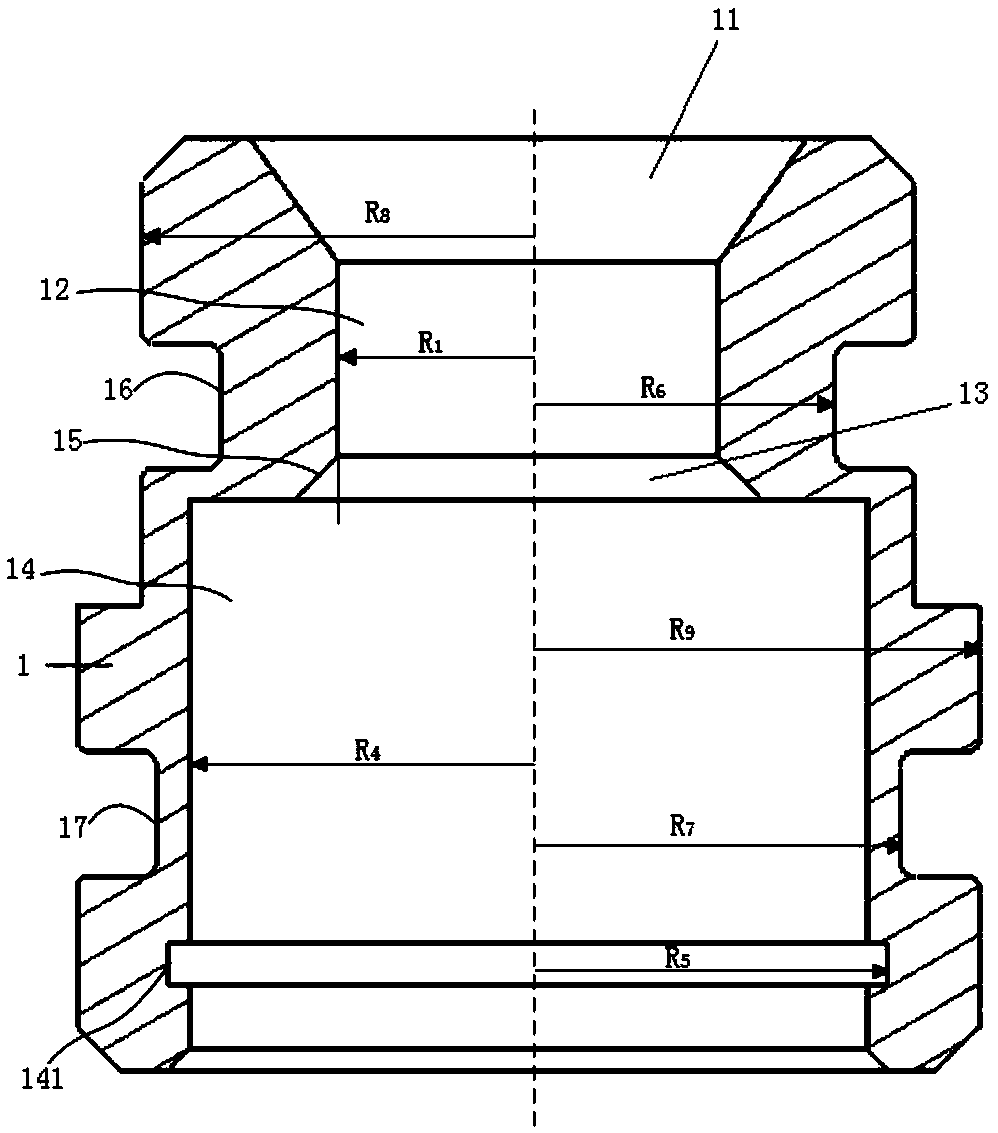

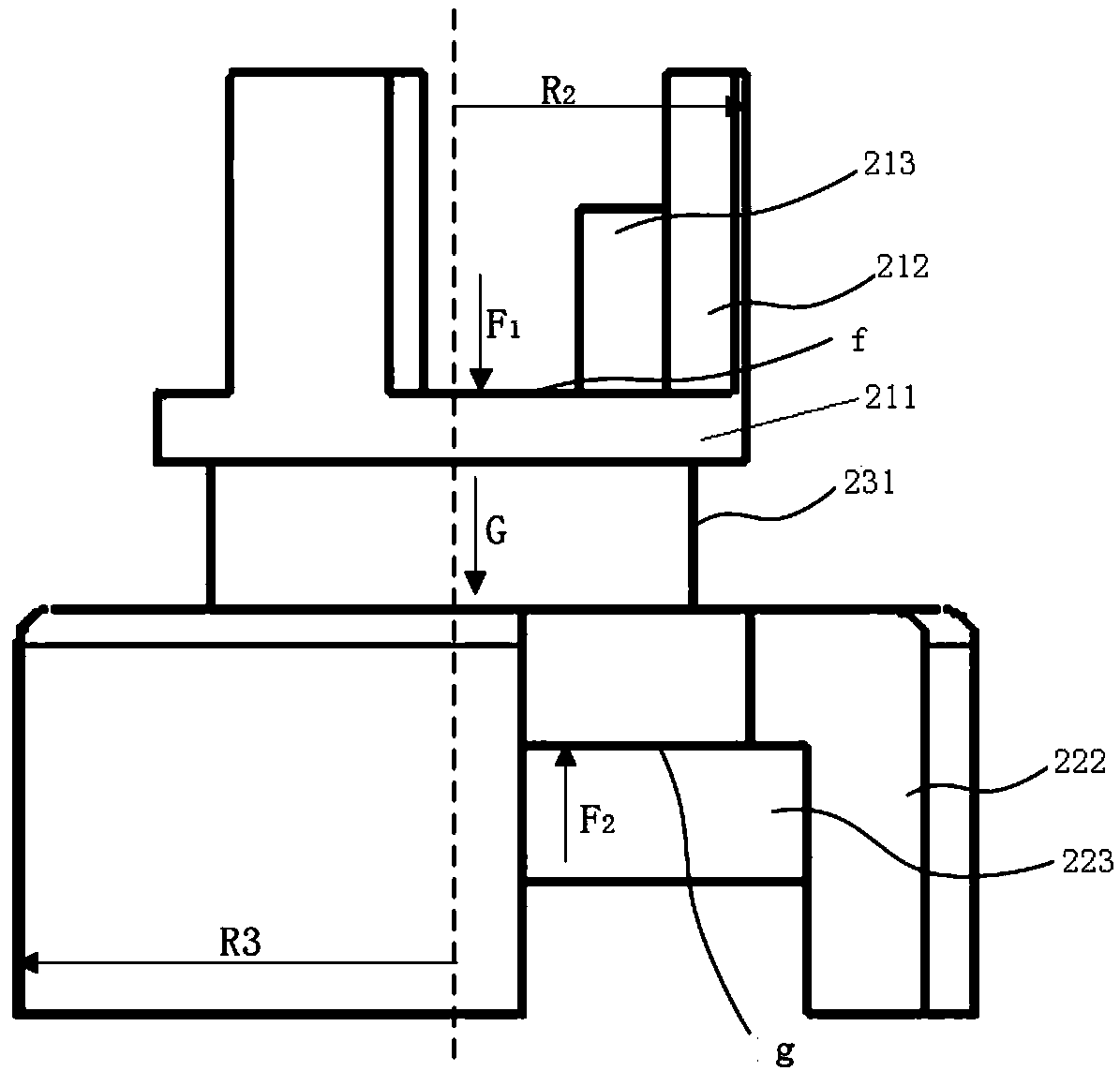

[0077] like Figure 1 to Figure 4 As shown, according to the first embodiment of the present invention, the built-in check valve of the present invention includes a valve body 1 , a valve core 2 and a snap ring 3 . in:

[0078] like figure 1 and figure 2 As shown, the inside of the valve body 1 has a circular cavity, and the circular cavity includes an inlet flow channel 11, a neck flow channel 12, a throat flow channel 13 and The outlet channel 14, the inlet channel 11, the neck channel 12, the throat channel 13 and the outlet channel 14 are concentric. The fluid enters the outlet channel 14 through the inlet channel 11 , the neck channel 12 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com