Coal seam gas well washing tool passing through glass fiber reinforced plastics screen pipe and method

A technology of coalbed methane wells and glass fiber reinforced plastics, which is applied in the direction of flushing boreholes, wellbore/well parts, cleaning tools, etc., which can solve the problems of increased number of well washouts, high pollution levels, and poor washout effects, so as to increase production and promote production capacity The release, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

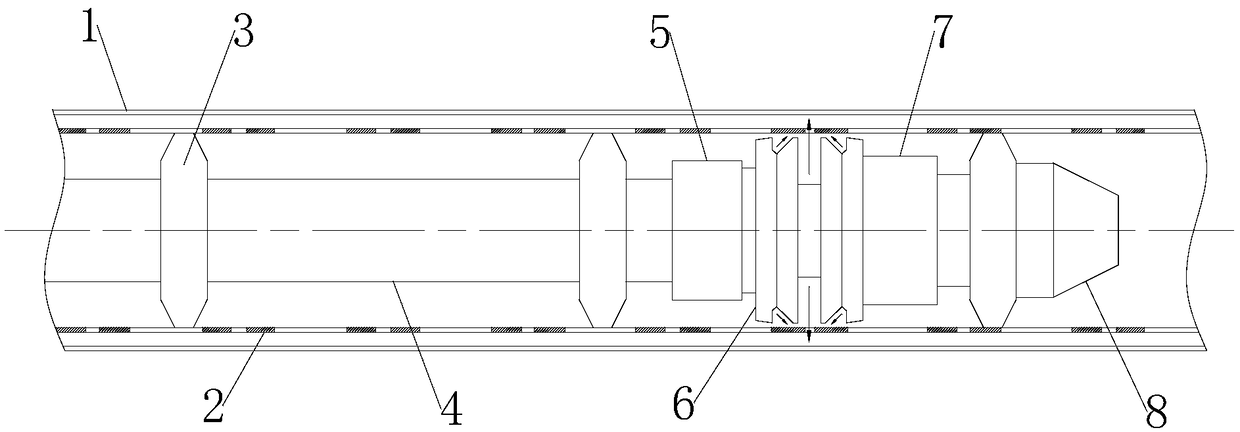

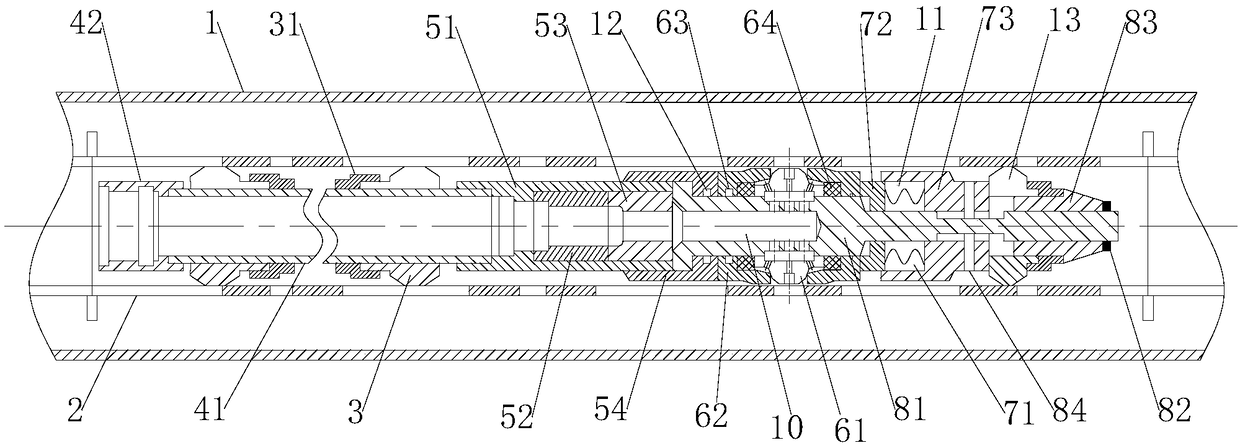

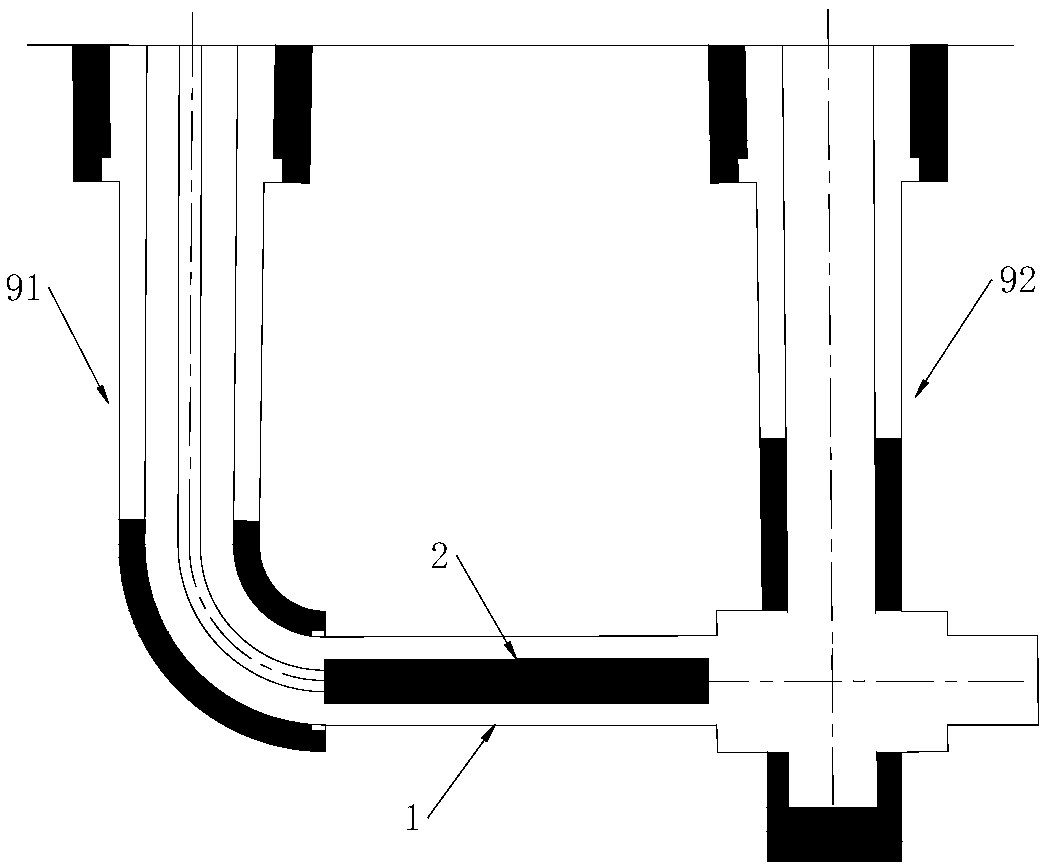

[0030] With reference to the accompanying drawings, a coalbed methane well flushing tool that passes through a glass fiber reinforced plastic screen includes a flushing pipe 4 , a jet oscillating nozzle 5 , a hydraulic sealing nozzle 6 , a pressure regulator 7 and a guide head 8 . The flushing pipe 4 is arranged in the center of the FRP slotted screen 2, and the outside of the FRP slotted screen 2 is the open hole 1 of the horizontal well, and a first elastic centralizing sleeve is arranged between the flushing pipe 4 and the FRP slotted screen 2 3. The flushing pipe 4 includes a pipe body 41 for transporting well flushing fluid. The first elastic centralizing sleeve 3 is fixed on the pipe body 41 through a retaining ring 31. One end of the pipe body 41 is provided with a collar 42, and the other end of the pipe body 41 is connected to the pipe body 41. The jet oscillating nozzle 5 is connected.

[0031] The jet oscillating nozzle 5 includes a nozzle body 51, one end of the n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com