Inner hole quenching inductor for dual-conical-surface bearing sleeve ring

A technology for quenching inductors and bearing rings, applied in the field of bearing inner ring quenching, can solve the problem of not being able to complete the quenching of the bearing inner ring at one time, and achieve the effects of ensuring quenching quality, reducing production costs, and simplifying processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

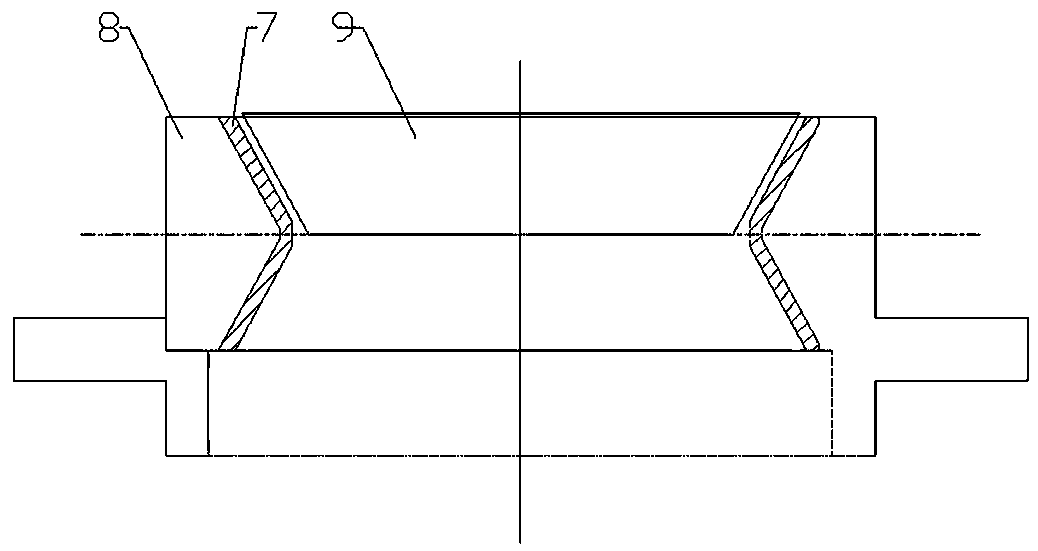

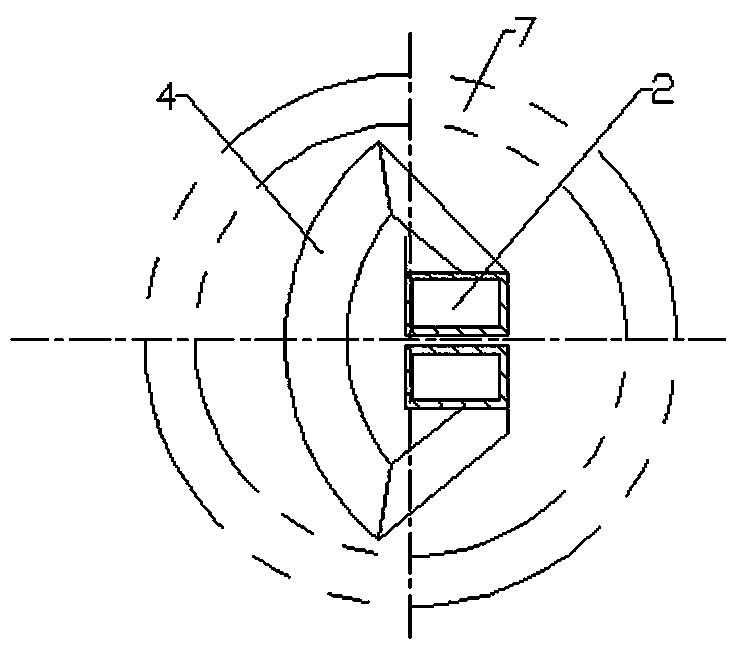

[0012] like figure 2 and image 3 As shown in the figure, a double-cone bearing ring inner hole quenching sensor includes a quenching transformer 1, a bus bar 2, and a water spray box 3. The front end of the bus bar is connected to the quenching transformer, and the water spray box is fixed at the tail end of the bus bar. On the right side; the tail end of the bus bar is provided with an upper arc-shaped effective circle 4 and a lower arc-shaped effective circle 5, and both the upper arc-shaped effective circle and the lower arc-shaped effective circle are provided with a magnetizer 6, and the upper arc The shaped effective ring and the lower arc effective ring are respectively used for heating the upper and lower taper surfaces of the inner ring 7 of the bearing.

[0013] The above technical solution is further defined, the outer circular surface of the upper arc-shaped effective ring is parallel to the upper cone surface of the bearing inner ring, and the outer circular su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com