Improved preparation method of zirconium tetrachloride and zirconium tetrachloride

A technology of zirconium tetrachloride and silicon tetrachloride, applied in the direction of zirconium halide, etc., can solve the problem of difficult removal of metal impurities, achieve the effect of reducing the difficulty of separation and purification, improving purity and quality, and improving purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The present embodiment provides a kind of preparation method of improved zirconium tetrachloride, comprises the following steps:

[0045]1) The zircon sand contains metal oxide impurities, and the metal oxide impurities in the zircon sand are removed to obtain purified zircon sand;

[0046] 2) Heating the purified zircon sand with a carbonaceous reducing agent and chlorine gas to react to generate a mixed gas of zirconium tetrachloride, silicon tetrachloride, carbon monoxide and carbon dioxide. Separate the mixed gas to obtain zirconium tetrachloride.

[0047] The improved zirconium tetrachloride preparation method in this example first removes the metal oxide impurities in the zircon sand, and then reacts with carbonaceous reducing agent and chlorine gas, which greatly reduces the obtained zirconium tetrachloride product. The content of the chloride of metal impurity in the middle, has avoided the chloride of metal impurity mixed in the zirconium tetrachloride product...

Embodiment 2

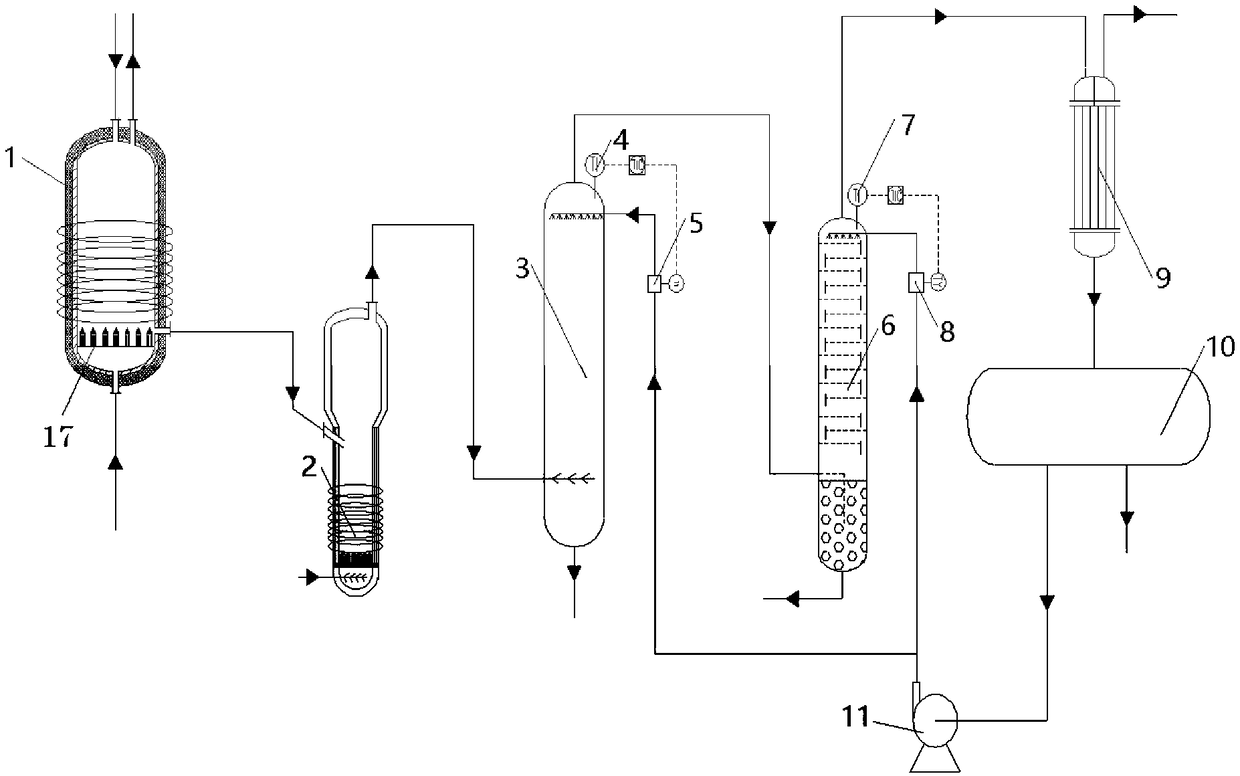

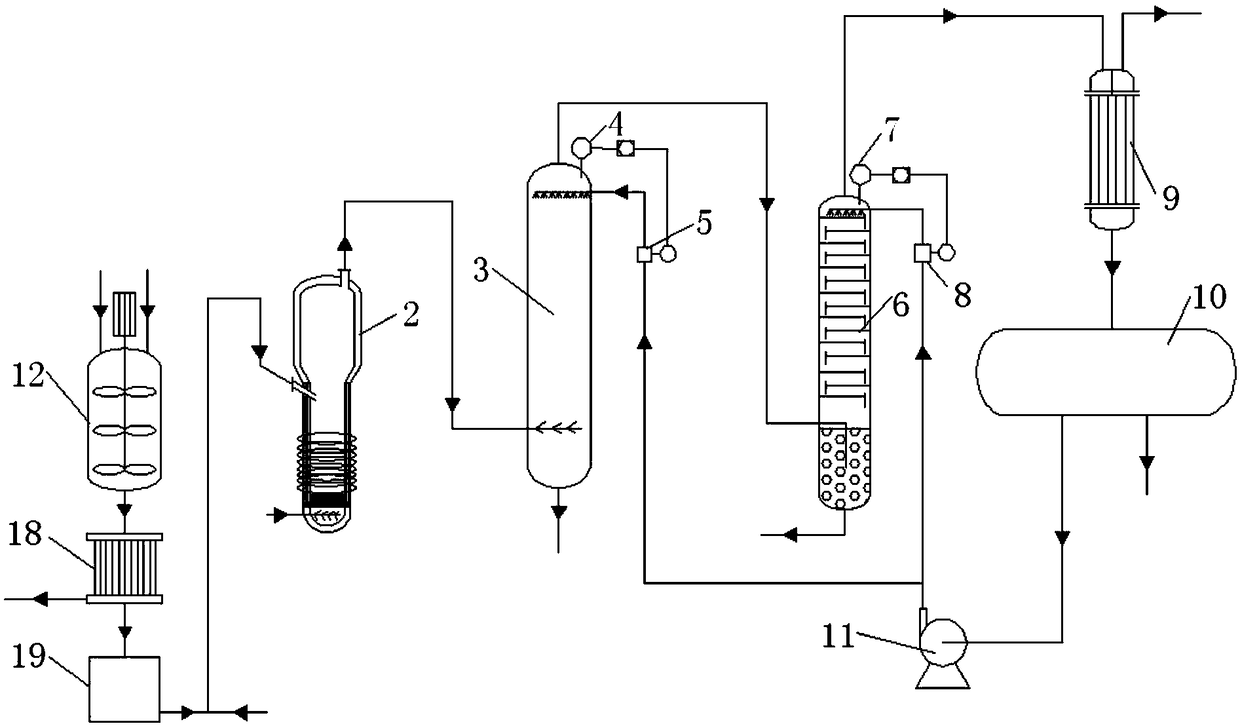

[0049] Such as figure 1 As shown, the present embodiment provides a kind of device for preparing zirconium tetrachloride, comprising:

[0050] Impurity removal reactor 1, zircon sand and reaction gas are mixed in the impurity removal reactor 1, the reaction gas is chlorine and hydrogen chloride, the impurity removal reactor 1 is heated, and the metal oxide impurities in the zircon sand react with the reaction gas to form a gaseous state The metal chloride, obtains purified zircon sand, first syngas, the first syngas comprises gaseous metal chloride;

[0051] The outside of the impurity removal reactor 1 is made of 800H alloy steel (nickel-based alloy), and the inner lining is zirconia and silicon nitride ceramic anticorrosion layer. The outside is equipped with an induction heater and a temperature controller. The internal temperature and the current of inductive heating are controlled in a cascade loop, which is used to control the temperature of the impurity removal reactor...

Embodiment 3

[0082] This embodiment provides a kind of preparation method of the improved zirconium tetrachloride using the device in embodiment 2, and the difference of the preparation method of the improved zirconium tetrachloride in embodiment 2 is:

[0083] The molar ratio of chlorine and hydrogen chloride in the reaction gas in step 2) is 4:1, and the impurity removal reactor is heated to 400°C for 5 hours,

[0084] In step 4), the mass ratio of zircon sand to carbonaceous reducing agent is 4.5:1, the chlorination reactor is heated to 1200° C., and the pressure is 50KPa. The carbonaceous reducing agent is petroleum coke.

[0085] In step 5), the liquid silicon tetrachloride is passed into the first washing tower from the top to wash the second synthesis gas and lower the temperature to 200°C.

[0086] In step 6), the liquid silicon tetrachloride is passed into the second washing tower from the top to wash the third synthesis gas and lower the temperature to 40°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com