Stable and safe hammer assembly

A safe and component technology, applied in the field of hand tools, can solve the problems of easy knocking of the hammer head and difficulty in finding nails, etc., to avoid knocking on the hand, prevent knocking and improve safety performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

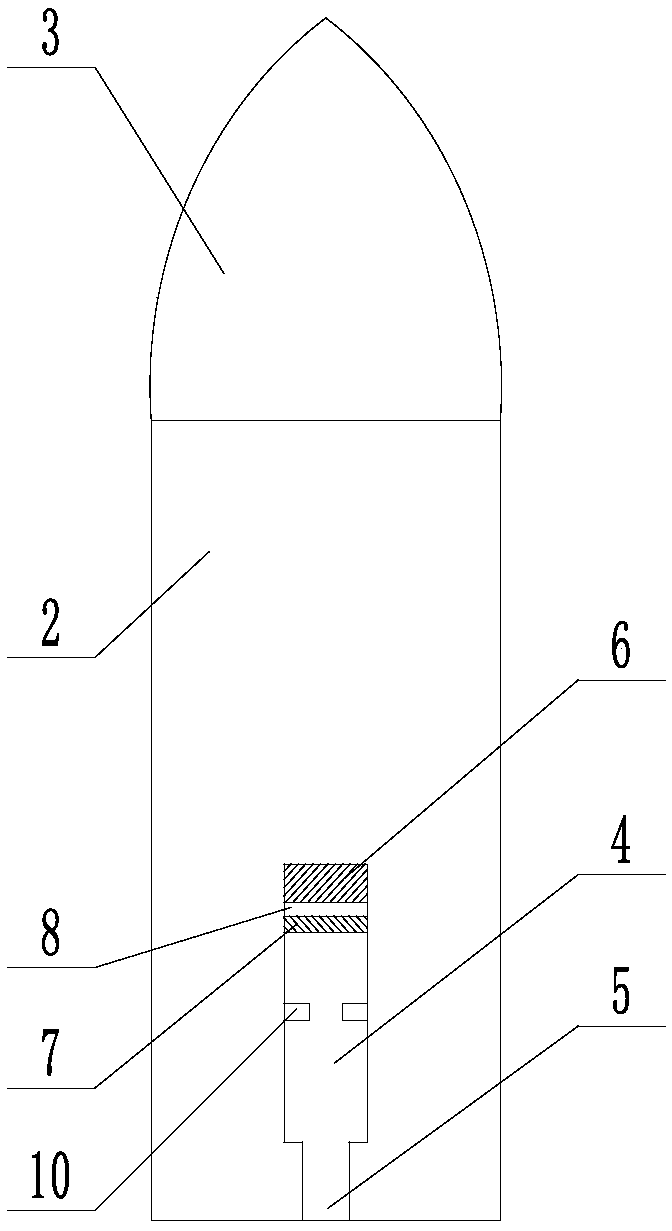

[0033] Such as Figure 1 to Figure 4 A stable and safe hammer assembly shown includes a rod body 1 connected to each other and a hammer head. The hammer head includes an integrally formed flat head 2 and a pointed cone 3. The flat head 2 is square. The side surface of the flat head 2 away from the direction where the rod body 1 is located is the front, and the side surface of the flat head 2 away from the direction where the pointed cone 3 is located is the bottom surface, and the front of the flat head 2 is provided with a first connected to each other. Groove 4, second groove 5, described second groove 5 is positioned between first groove 4 and the bottom surface of flat head 2, and described second groove 5 is open at the bottom surface of described flat head 2 Mouth, the width and depth of the second groove 5 are smaller than the first groove 4; the side wall in the first groove 4 away from the direction where the second groove 5 is fixed permanent magnet plate 6, the firs...

Embodiment 2

[0035] Such as Figure 1 to Figure 5 The shown stable and safe hammer assembly, on the basis of Embodiment 1, also includes an anti-knock assembly, and the anti-knock assembly includes a strip-shaped push plate 13, and one end of the push plate 13 along the long axis direction Two clamping plates 14 are fixedly connected, and the two clamping plates 14 are symmetrical to the long axis of the push plate 13. A clamping seam 15 is formed between the two clamping plates 14, and the clamping seam 15 is along the length of the push plate 13. In the direction of the long axis, the width increases linearly from one end close to the push plate 13 to one end far away from the push plate 13 . The clamping plate 14 is fan-shaped with a central angle of 85°, and one side of the fan-shaped is attached to the side of the push plate 13 . The thickness of the push plate 13 and the clamping plate 14 are equal, and the upper and lower surfaces of the push plate 13 and the clamping plate 14 are ...

Embodiment 3

[0037] Such as Figure 1 to Figure 6 The shown stable and safe hammer assembly, on the basis of Embodiment 2, also includes a mounting block 16 fixed on the upper surface of the push plate 13, the top of the mounting block 16 is provided with a first force transmission plate 17, and the first A force transmission plate 17 is hinged on the top of the mounting block 16 away from the end of the clamping plate 14, and an elastic member 18 is connected between the bottom surface of the first force transmission plate 17 and the top surface of the mounting block 16; The L-shaped piece 19 on the side of the direction of 14, the L-shaped piece 19 is bent upwards, the top of the L-shaped piece 19 is provided with a slider 20, and also includes a driving block 21, and the bottom surface of the driving block 21 is arranged on the same side as the The sliding block 20 matches the sliding rail 22, the sliding block 20 is located in the sliding rail 22, the length direction of the sliding ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com