Seamless flux-cored powder and submerged arc welding wire for LPG ship welding and preparation and application

A technology of submerged arc welding wire and flux core powder, which is applied in the direction of welding equipment, welding medium, welding/cutting medium/material, etc., which can solve the problems of late start, achieve strong moisture absorption resistance, good fusion, and reduce the content of diffusible hydrogen Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

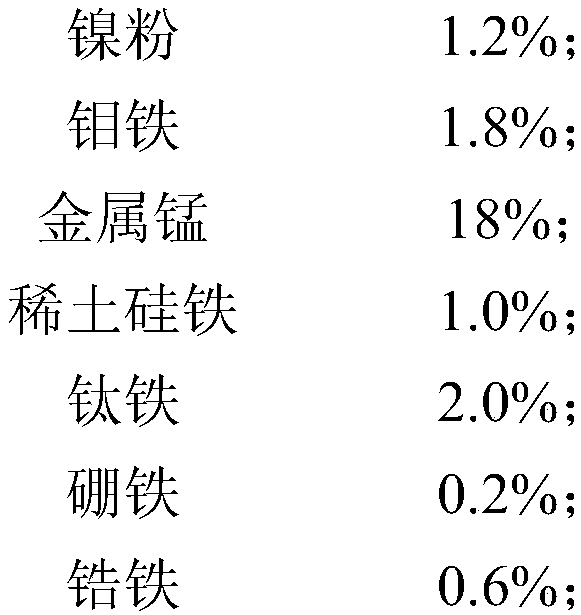

[0055] A seamless core powder for LPG ship welding, comprising the following components by mass percentage:

[0056]

[0057]

[0058] A preparation method for submerged arc welding wire, comprising the steps of:

[0059] (1) Distributing and mixing the components of the seamless core powder for LPG ship welding to obtain the seamless core powder for LPG ship welding;

[0060] (2) The seamless flux core powder for LPG ship welding obtained in the step (1) of wrapping the low-carbon steel strip on the outer skin is rolled (including steel strip mouth welding) and reduced in diameter to obtain a submerged arc welding wire, wherein the LPG ship The mass of the seamless flux core powder for welding is 12% of the total mass of the submerged arc welding wire.

[0061] (3) The submerged arc welding wire prepared in step (2) is further coiled, packaged, and put into storage.

Embodiment 2

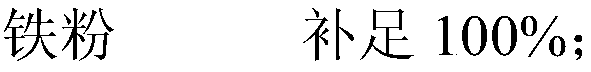

[0063] A seamless core powder for LPG ship welding, comprising the following components by mass percentage:

[0064]

[0065] A preparation method for submerged arc welding wire, comprising the steps of:

[0066] (1) Distributing and mixing the components of the seamless core powder for LPG ship welding to obtain the seamless core powder for LPG ship welding;

[0067] (2) The seamless flux core powder for LPG ship welding obtained in the step (1) of wrapping the low-carbon steel strip on the outer skin is rolled (including steel strip mouth welding) and reduced in diameter to obtain a submerged arc welding wire, wherein the LPG ship The mass of the seamless flux core powder for welding is 15% of the total mass of the submerged arc welding wire.

[0068] (3) The submerged arc welding wire prepared in step (2) is further coiled, packaged, and put into storage.

Embodiment 3

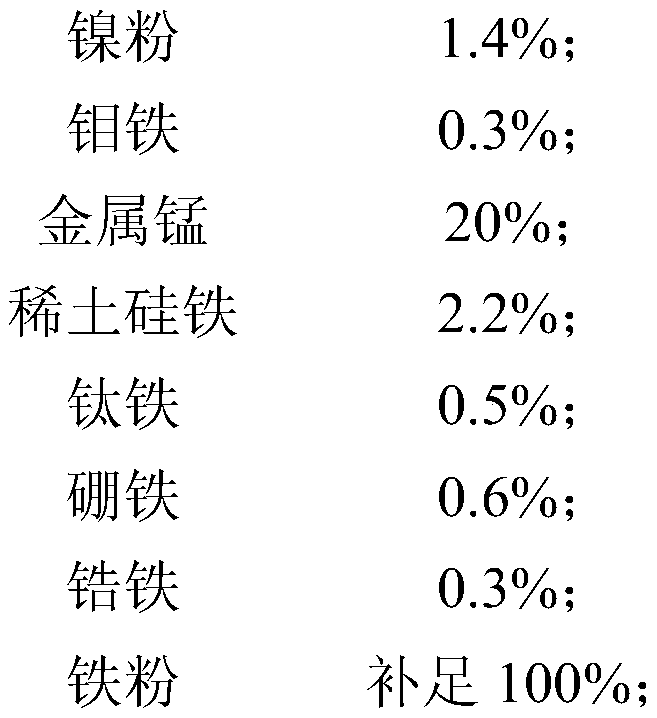

[0070] A seamless core powder for LPG ship welding, comprising the following components by mass percentage:

[0071]

[0072]

[0073] A preparation method for submerged arc welding wire, comprising the steps of:

[0074] (1) Distributing and mixing the components of the seamless core powder for LPG ship welding to obtain the seamless core powder for LPG ship welding;

[0075] (2) The seamless flux core powder for LPG ship welding obtained in the step (1) of wrapping the low-carbon steel strip on the outer skin is rolled (including steel strip mouth welding) and reduced in diameter to obtain a submerged arc welding wire, wherein the LPG ship The mass of the seamless flux core powder for welding is 9% of the total mass of the submerged arc welding wire.

[0076] (3) The submerged arc welding wire prepared in step (2) is further coiled, packaged, and put into storage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com