Welding process of inclined tubes

A welding process and inclined tube technology, applied in welding equipment, manufacturing tools, tubular objects, etc., can solve the problems of high separation rate and low welding efficiency, achieve high automation, high welding efficiency, and avoid damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

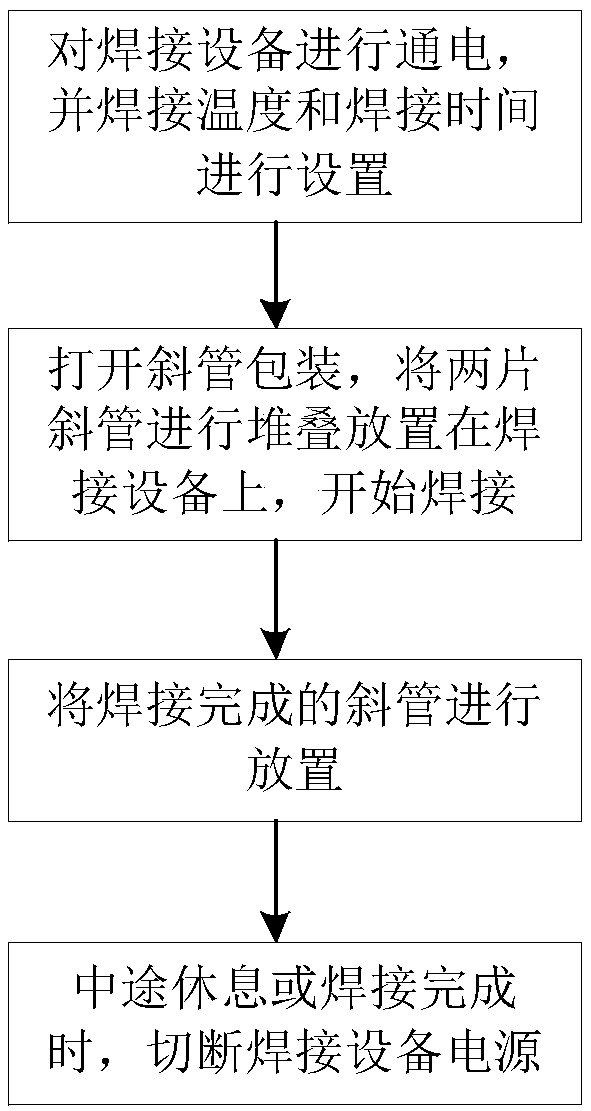

[0021] A kind of inclined pipe welding process such as figure 1 As shown, the equipment used for welding is multiple groups of multi-point evenly distributed high-frequency automatic welding equipment. button, the temperature and numerical control integrated system and the LCD display are in working condition, set the welding temperature to 170°C and the welding time for 1 second through the digital keyboard, then turn off the first power button that controls the temperature and numerical control integrated system, open the package of the inclined tube, and put The first piece of inclined tube is placed flat in the notch of the lower support module of the inclined tube on the installation platform of multiple groups of multi-point uniformly distributed high-frequency automatic welding equipment, and another piece of inclined tube is taken out and placed on the first piece of inclined tube. It is 60° and has a hexagonal honeycomb shape. After the inspection is correct, start to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com