Ultrafast ultraviolet laser processing method and device of transparent material

A transparent material and ultraviolet laser technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of limited processing and achieve the effect of improving removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

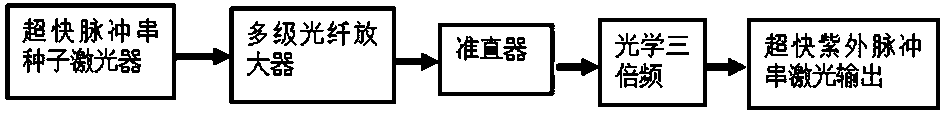

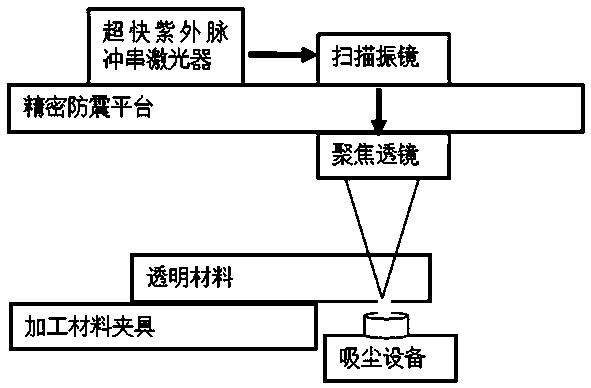

[0040] Embodiment one: see figure 2 As shown, a processing device for transparent materials is composed of an ultrafast ultraviolet pulse train laser, a scanning galvanometer, and a focusing lens. See figure 1 , the ultraviolet ultrafast burst laser is mainly composed of a burst seed laser with an output wavelength between 1020 nanometers and 1090 nanometers, a multi-stage or single-stage fiber amplifier, a collimator, and a frequency tripler device. The burst seed laser After the output light is amplified by the fiber amplifier, it is collimated by the collimator to output the laser pulse train; the optical triple frequency is performed to obtain the ultraviolet output with a wavelength of 510nm-545nm, and the ultraviolet laser pulse train is output. The laser pulse train is focused on the position of the transparent material to be processed by the focusing lens after passing through the scanning galvanometer. The ultraviolet ultrafast pulse train laser and the scanning gal...

Embodiment 2

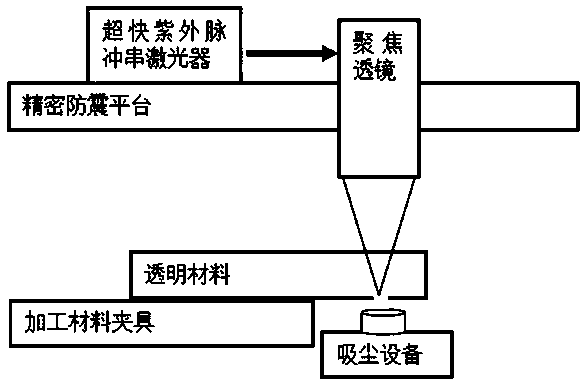

[0042] Embodiment two: see attached image 3 As shown, a transparent material processing device is composed of an ultrafast pulse train laser and a focusing lens, see figure 1 , the ultrafast burst laser is mainly composed of an ultrafast burst seed laser with an output wavelength between 1020 nanometers and 1090 nanometers, a multi-stage or single-stage fiber amplifier, a collimator and a frequency tripler device, and the burst seed laser After the output light is amplified by the fiber amplifier, the laser pulse train is output after being collimated by the collimator; the optical triple frequency is performed to obtain the ultraviolet output with a wavelength of 510nm-545nm, and the ultraviolet laser pulse train is output. The laser pulse train is focused by the focusing lens on the position of the transparent material to be processed. Below the transparent material, corresponding to the position to be processed, there is a dust suction device for recycling the removed mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com