Tube cleaning assembly and tube cleaning method

A technology for cleaning components and pipelines, applied in the directions of cleaning methods and utensils, cleaning hollow objects, chemical instruments and methods, etc., can solve problems such as affecting production capacity, and achieve the effect of improving running time, not easy to condense, and reducing production capacity loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

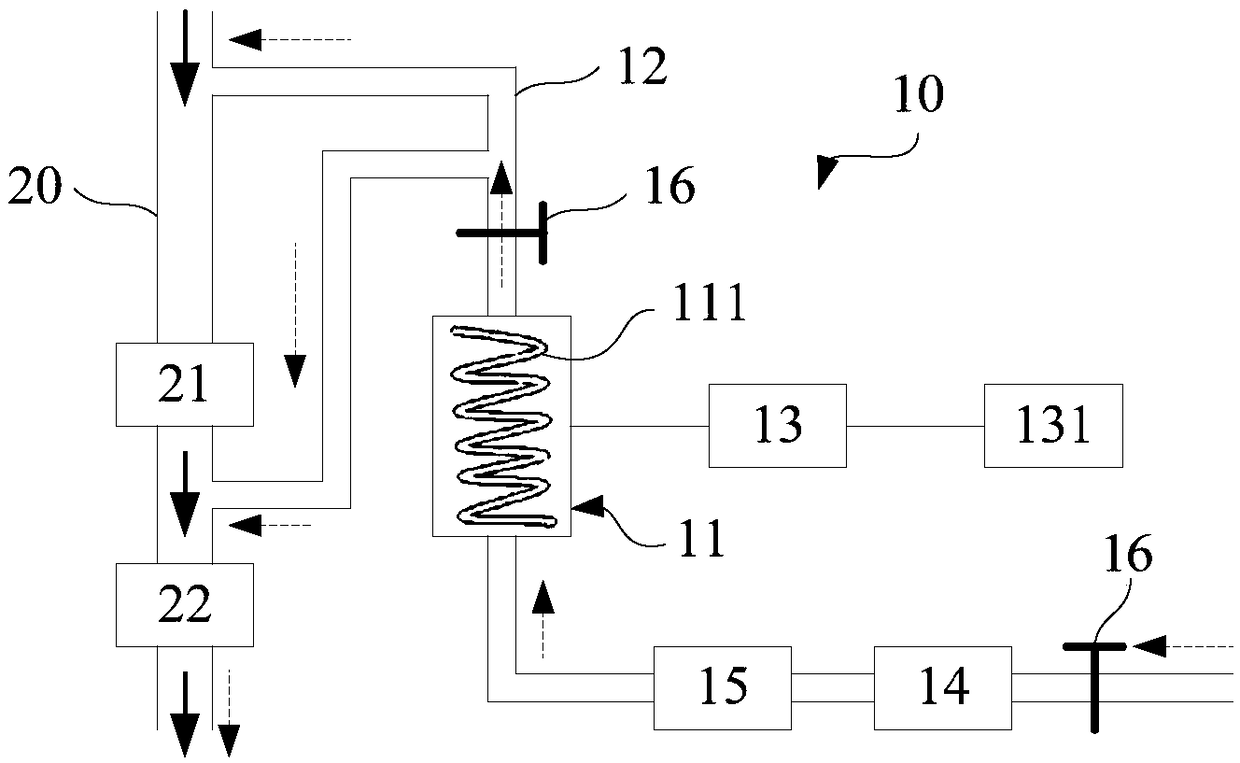

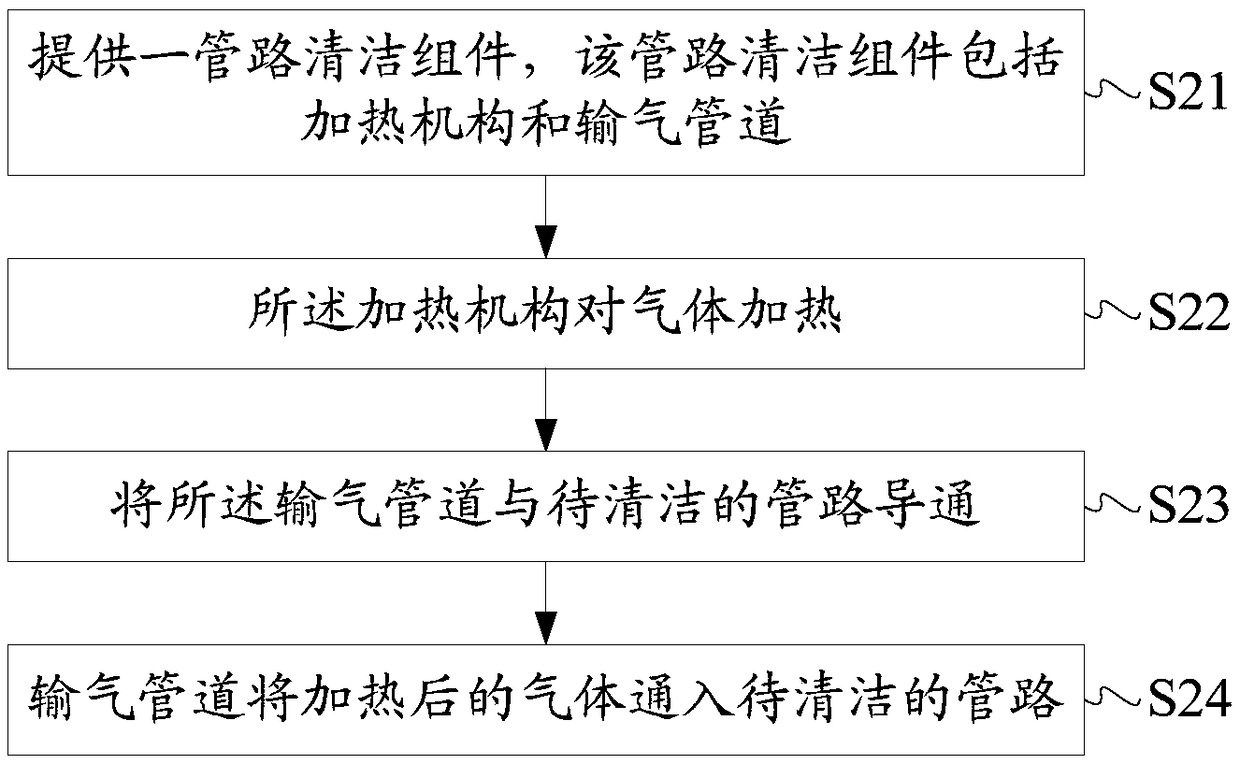

[0013] The main purpose of this application is to design a pipeline cleaning assembly including a heating mechanism and a gas delivery pipeline, the heating mechanism heats the gas, the gas delivery pipeline is connected to the pipeline to be cleaned to pass the heated gas into the pipeline, and the gas conducts heat to the pipeline. Dust pollutants make it difficult for dust pollutants to condense, which is beneficial to prevent blockage in the pipeline. During the entire cleaning process, since there is no need to disassemble the pipeline for maintenance, it is beneficial to improve equipment running time and reduce production loss. .

[0014] The pipeline cleaning assembly of the present application can be applied to manufacturing equipment containing special gas processes in the field of display device manufacturing, such as chemical vapor deposition machines, dry etching machines, and flexible packaging machines. Wherein, the gas introduced into the special gas manufactur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com