Serum pipette full-automatic leakage measuring and dust removing integration mechanism

A pipette, fully automatic technology, applied in the direction of measuring the acceleration and deceleration rate of fluid, using liquid/vacuum for liquid tightness measurement, measuring device, etc., can solve the problems of low labor intensity and low detection cost, etc. Achieve the effect of less time consumption, high detection efficiency, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

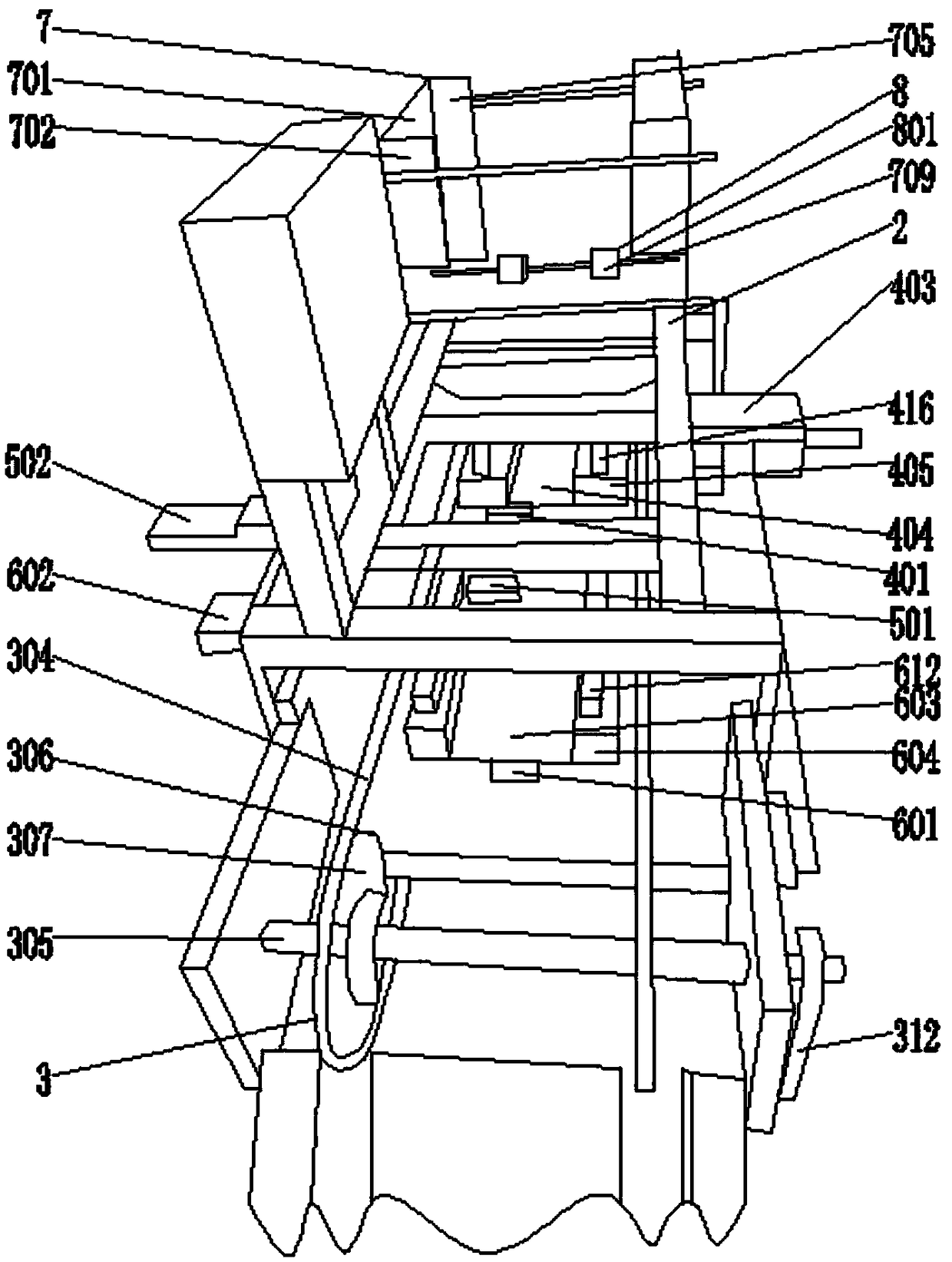

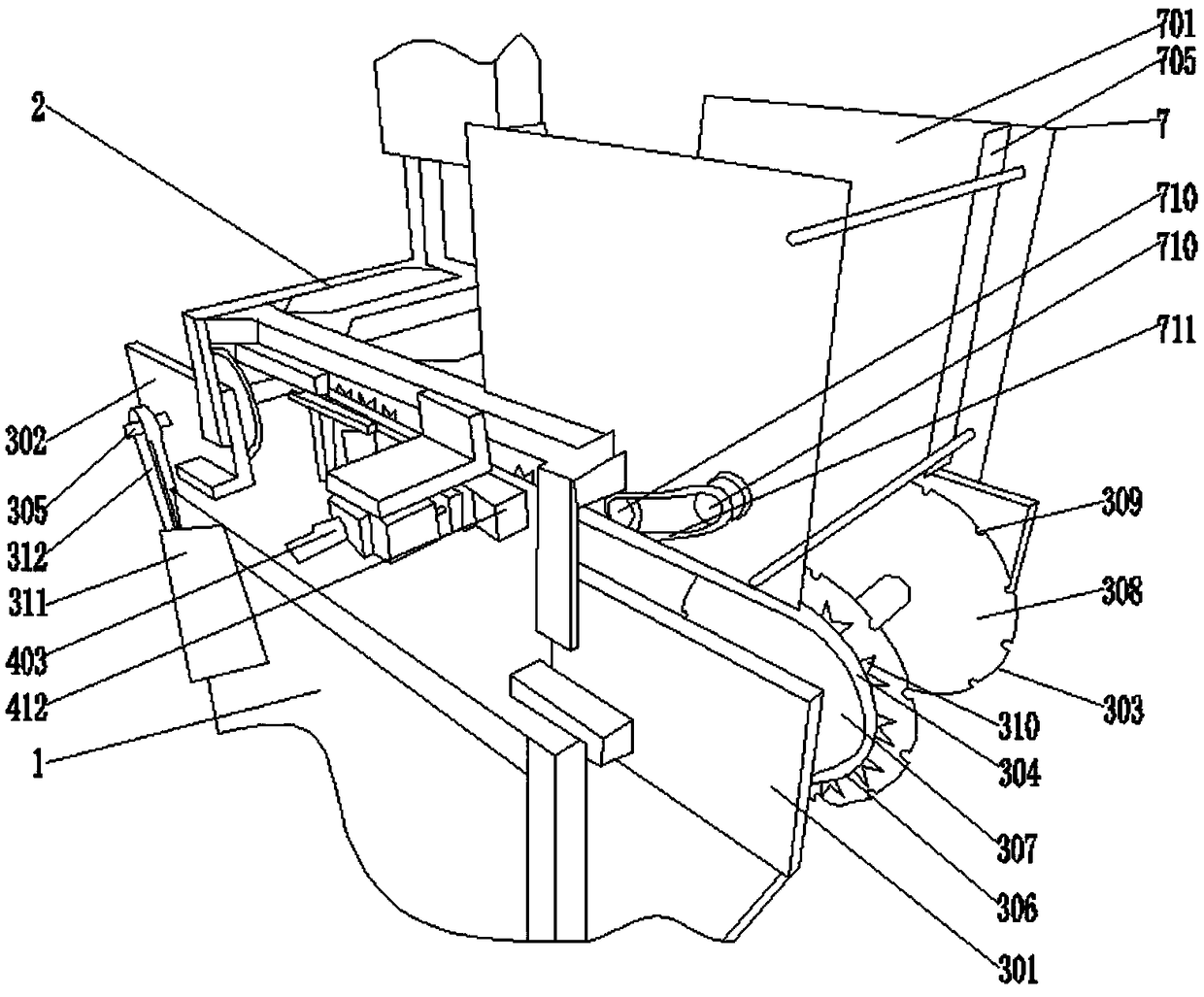

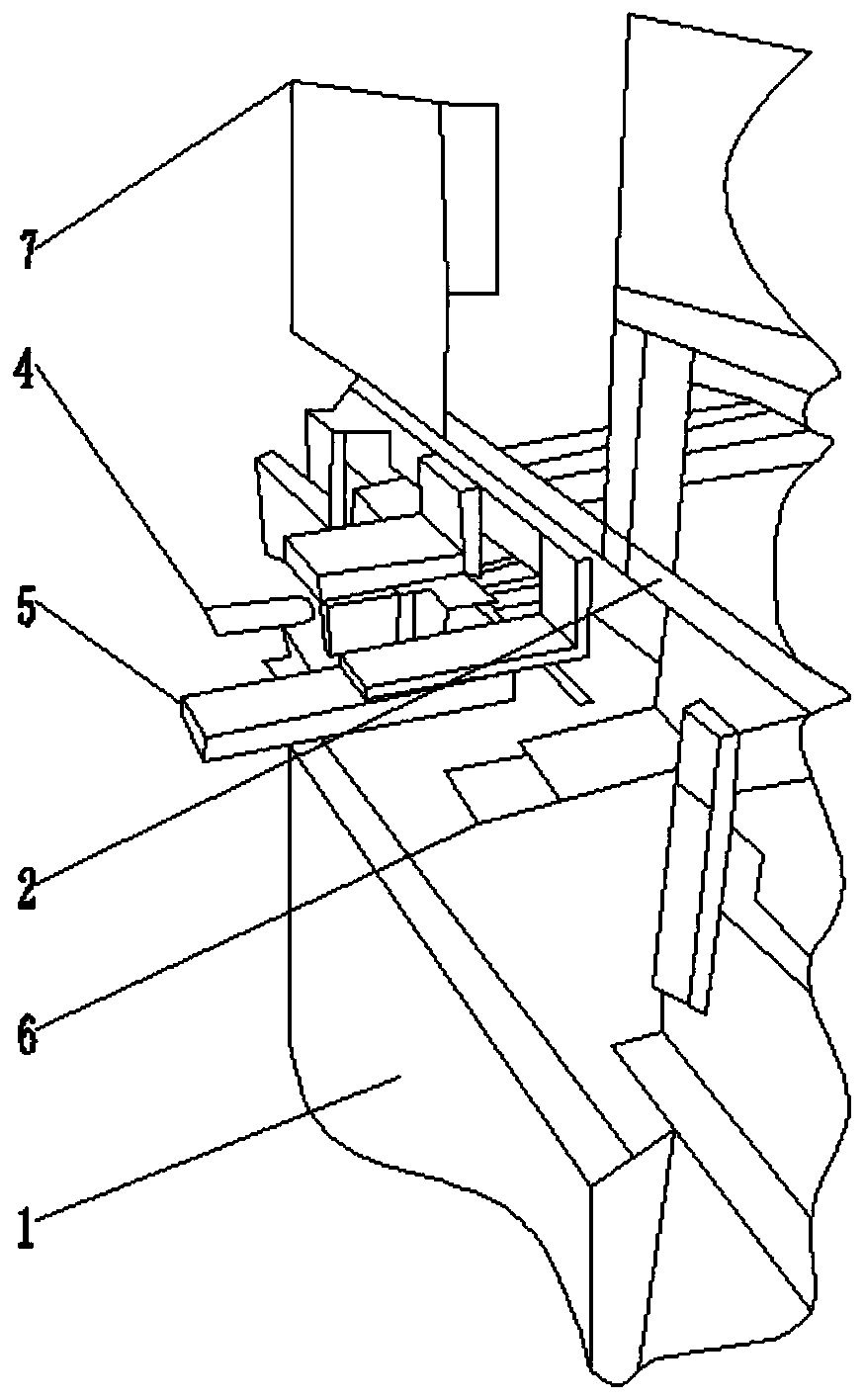

[0042] Such as figure 1 , figure 2 and image 3 The shown serological pipette automatic leak detection and dust removal integrated mechanism includes a cabinet body 1 and a bracket 2 arranged on the cabinet body. The cabinet body is equipped with such Figure 8 The conveying device 3 shown, the conveying device is positioned at the bottom of the bracket, and the cabinet body is provided with such Figure 4 The shown leak detection device 4, such as Figure 9 The reject device shown in 5 and as Figure 12 The shown dust removal device 6; the conveying device includes a first support plate group 301 arranged at the input end of the cabinet and a second support plate group 302 arranged at the output end of the cabinet body, and both the first support plate group and the second support plate group ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com