A fully automatic three-dimensional conveyor

A fully automatic conveyor technology, applied in the direction of conveyors, mechanical conveyors, conveyor objects, etc., can solve problems such as unstable operation, conveyors that cannot be applied to high-rise buildings, and a low degree of automation, achieving a high degree of automation and shortening The effect of excellent delivery time and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1, taking the application in a two-story building as an example.

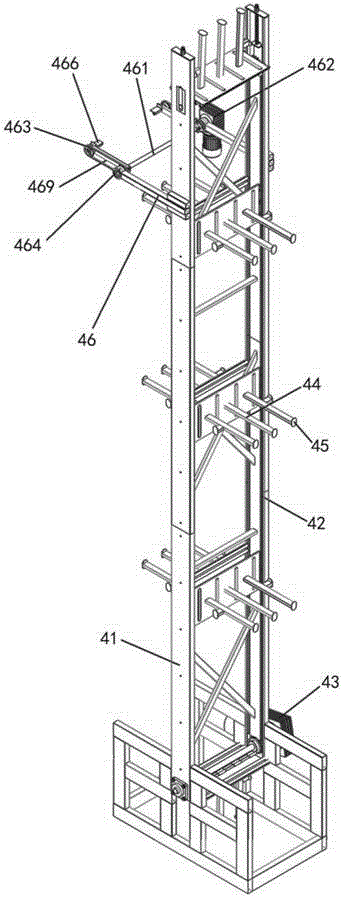

[0035] see figure 1 , a full-automatic three-dimensional conveyor, which includes a first horizontal transfer mechanism 1 for horizontally conveying the dinner plates, a vertical lifting mechanism 4 for lifting the dinner plates to the second floor, and a The second horizontal transmission mechanism 2, the third horizontal transmission mechanism 3 for realizing the horizontal movement of the dinner plate on the second floor, and the sensor system for realizing the automatic transfer of the dinner plate.

[0036] Such as Figure 4 As shown, the first transverse transmission mechanism 1 includes a transition plate 11 that is misplaced with the support plate of the vertical lifting mechanism, guide strips 12 arranged on both sides of the transition plate, and two first timing belts 13 installed inside the two guide strips 12 , and the first motor 14 for driving the first synchronous belt. The ...

Embodiment 2

[0046] Embodiment 2, taking the application in a three-story building as an example.

[0047] see Figure 5 , a full-automatic three-dimensional conveyor, which includes a first horizontal transmission mechanism 1 for horizontally conveying the dinner plates, a vertical lifting mechanism 4 for lifting the dinner plates to the required floor, and is arranged on the descending side of the vertical lifting mechanism The second transverse transfer mechanism 2, the third transverse transfer mechanism 3 used to realize the horizontal movement of the dinner plate on the required floor, and the sensor system used to realize the automatic transfer of the dinner plate. Two transfer structures 46 as described in Embodiment 1 are arranged at intervals on the above-mentioned vertical lifting mechanism 4 , and correspondingly, two groups of third transverse transfer mechanisms 3 are also arranged correspondingly.

[0048] Such as Figures 5 to 7 As shown, the above-mentioned sensing syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com