Ultraviolet curing machine

A technology of ultraviolet light and curing machine, which is applied in the direction of pretreatment surface, coating, and liquid coating device on the surface, etc., which can solve the problems of untimely heat dissipation of ultraviolet light source group, messy ventilation duct layout, which is not conducive to popularization and use, etc. Achieve the effect of low noise, good heat dissipation effect and ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments.

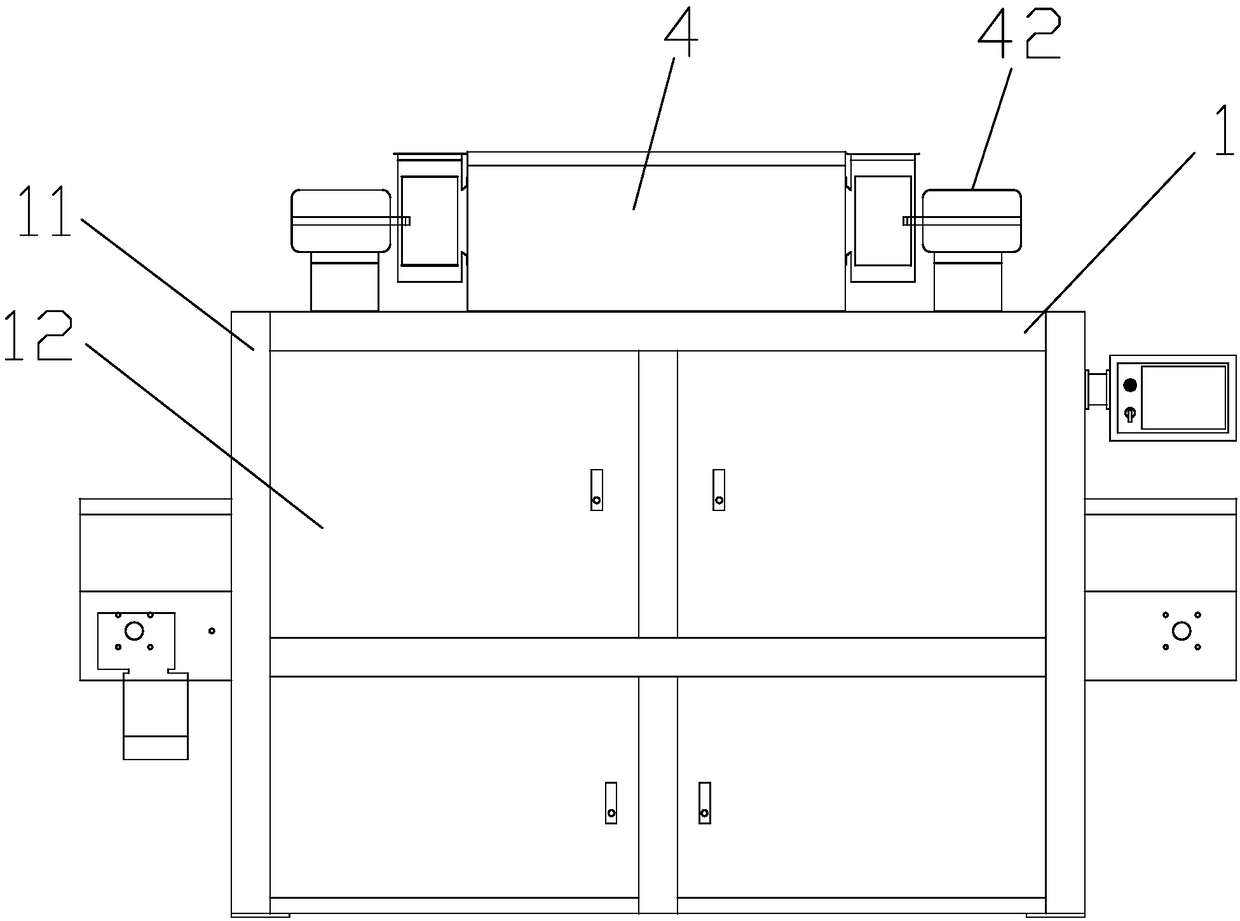

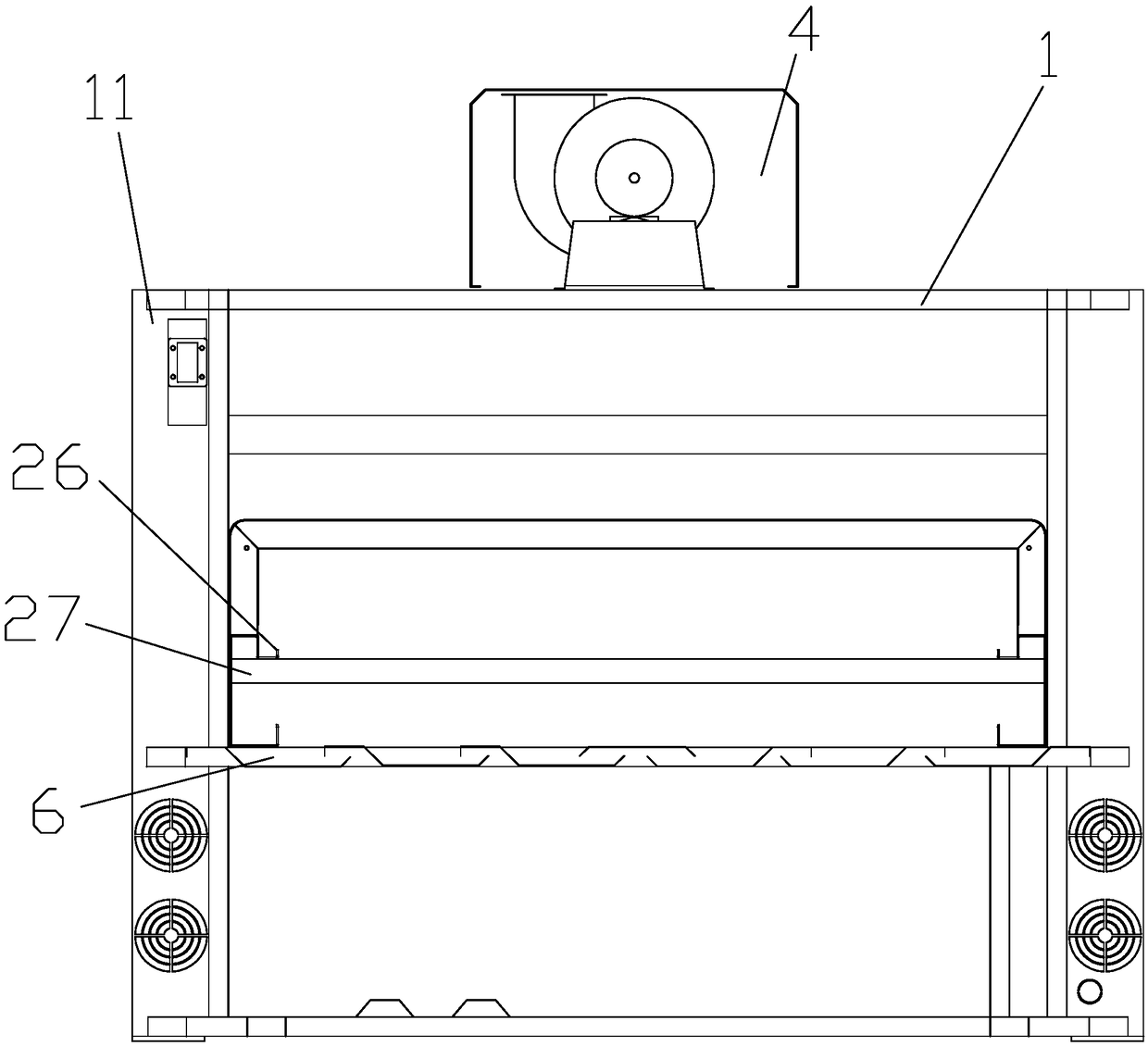

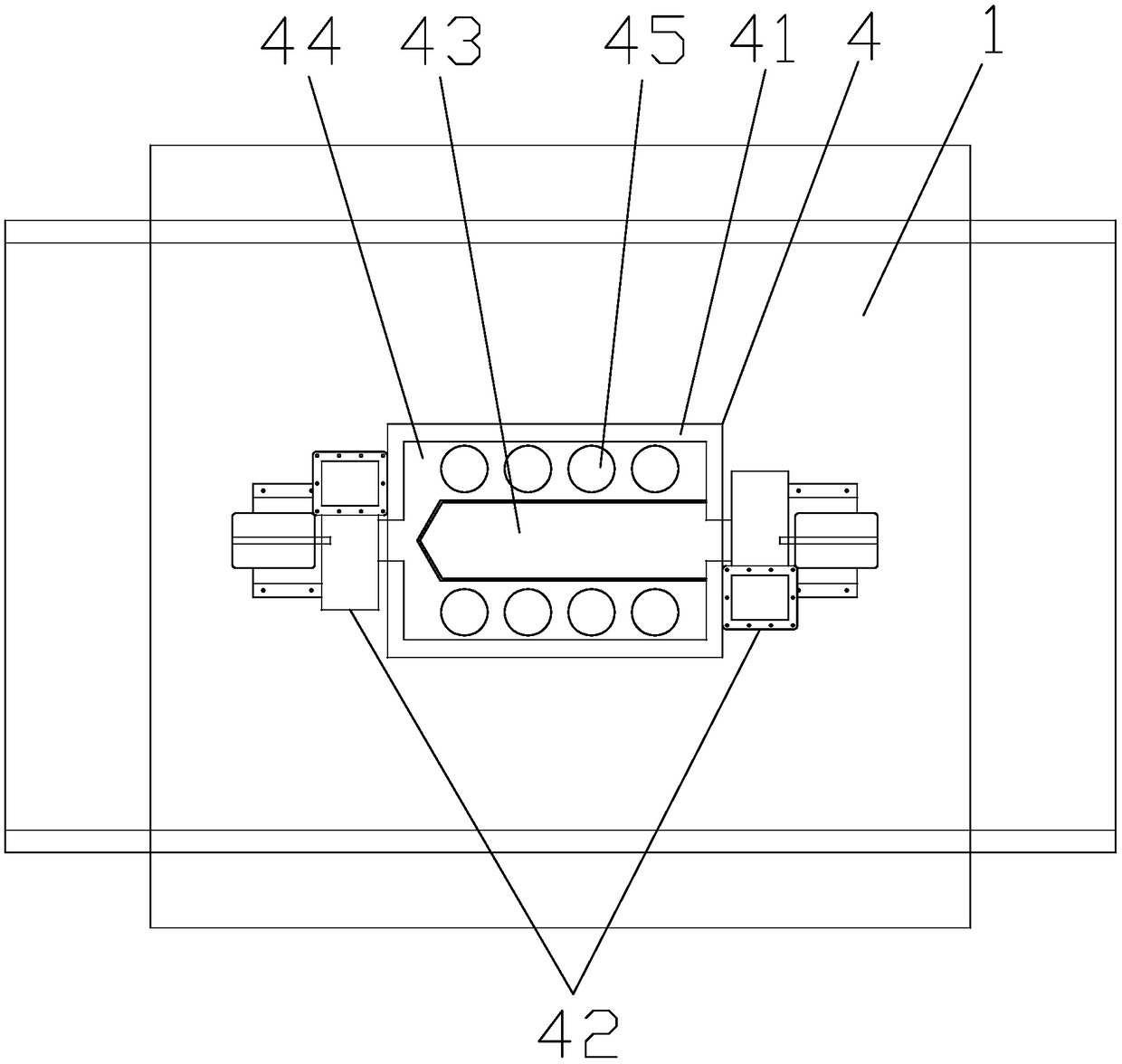

[0026] refer to Figure 1 to Figure 9 , what this embodiment discloses is a kind of ultraviolet curing machine, comprises cabinet 1, the product conveying roller 2 that is arranged in the cabinet 1, the multiple ultraviolet light source group 3 that is arranged on the product conveying roller 2, is arranged on the cabinet 1 Ventilation device 4. In this embodiment, the cabinet 1 includes a frame 11 made up of six columns, a housing arranged on the frame 11 and an inspection door 12 installed on the frame 11. For the convenience of maintenance and o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com