Preparation method of a novel magnetic self-assembled three-dimensional paper chip

A self-assembly, paper chip technology, applied in chemical instruments and methods, laboratory containers, laboratory utensils, etc., to achieve the effect of simplifying preparation steps, reducing production costs, and reducing chip packaging steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] This embodiment provides a method for preparing a novel magnetic self-assembled three-dimensional paper chip, comprising the following steps:

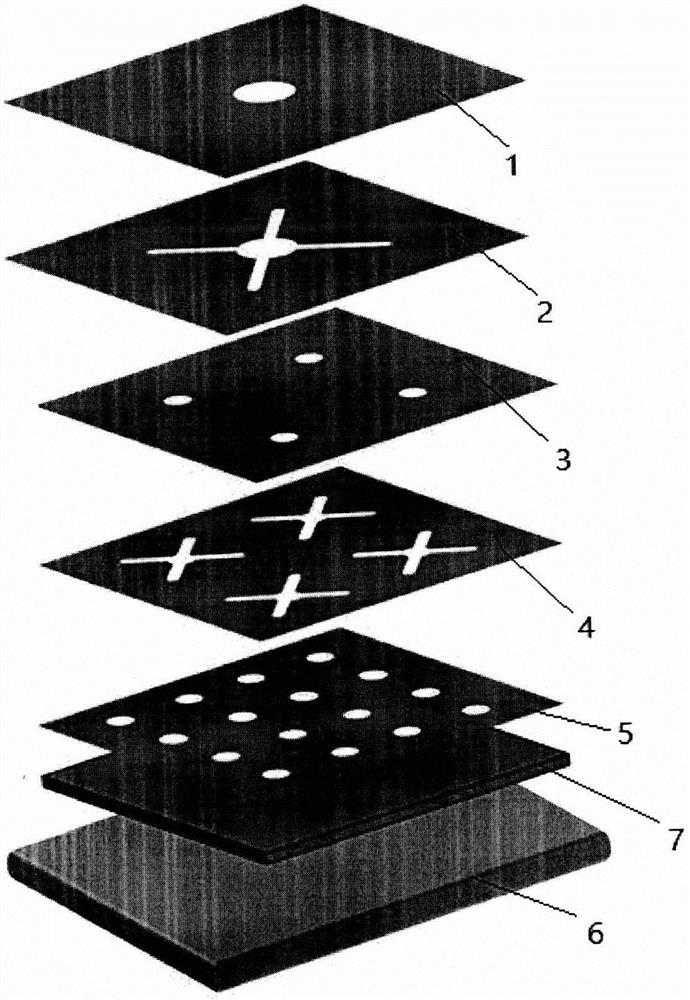

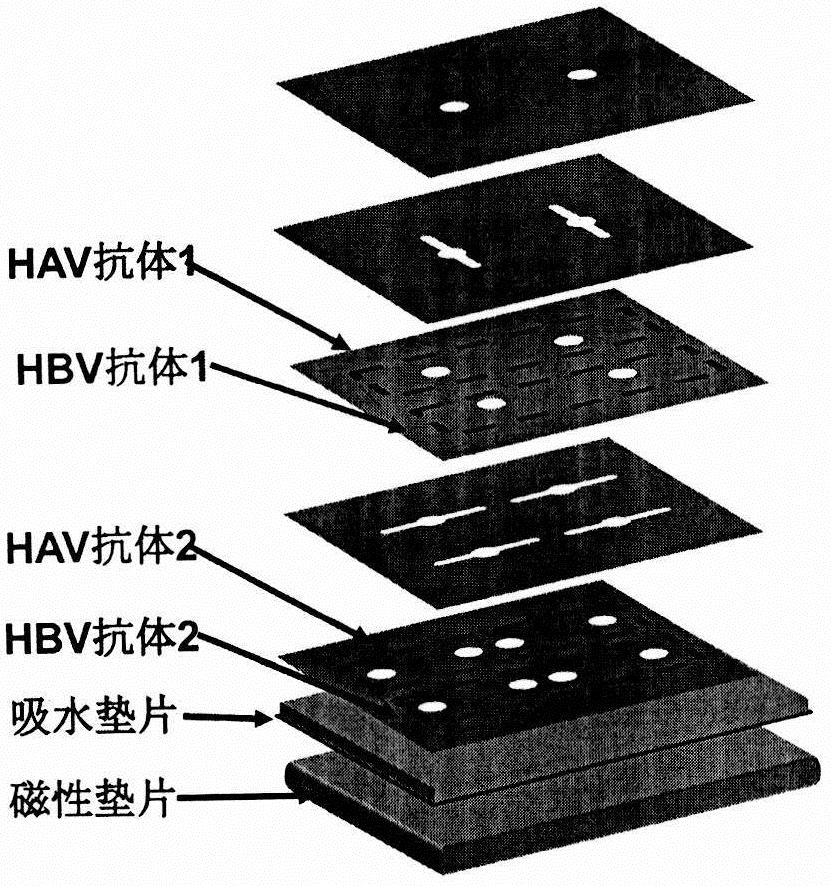

[0033] S101, using hydrophobic magnetic ink, and obtaining the channel layer, pretreatment reagent layer 3 and detection layer 5 of the paper chip respectively by screen printing;

[0034] Mix the hydrophobic ink and the magnetic powder material evenly to obtain the hydrophobic magnetic ink, use a scraper to screen-print the hydrophobic magnetic ink on the paper through the patterned printing ink, penetrate into the paper, and form a hydrophobic area, and the unprinted part is a hydrophilic area, respectively Obtain the channel layer, pretreatment reagent layer and detection layer of the paper chip.

[0035] Specifically, a 120-mesh patterned nylon printing ink screen was selected with a screen tension of 15 N / cm, and the designed pattern was printed on filter paper with hydrophobic magnetic ink using the screen, and dried in th...

Embodiment 2

[0045] This embodiment provides a method for preparing a novel magnetic self-assembled three-dimensional paper chip, comprising the following steps:

[0046] S201, using hydrophobic magnetic ink, and obtaining the channel layer of the paper chip, the pretreatment reagent layer 3 and the detection layer 5 respectively by screen printing;

[0047] Select a 100-mesh patterned ink-printed nylon screen, and print the magnetic hydrophobic printing solution on the nitrocellulose membrane. The screen tension during printing is 18N / cm, the composition of the hydrophobic ink is composed of screen printing ink and ethyl acetate with a volume ratio of 3:1, the magnetic powder is 150-250 mesh ferric oxide magnetic powder, and the ratio of hydrophobic ink to magnetic powder is The weight ratio is 1:0.8. The screen distance between the printing ink screen and the nitrocellulose membrane is 1.0mm during printing, the angle of the scraper and the printing ink screen is 50°, the printing speed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com