Device used for absorbing VOC with high boiling point solvent and recycling

A high-boiling-point solvent and suction chamber technology, applied in gas treatment, membrane technology, dispersed particle separation, etc., can solve serious problems, air pollution, and high cost of environmental protection treatment, and achieve low cost, pollution reduction, and reasonable overall structure settings Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

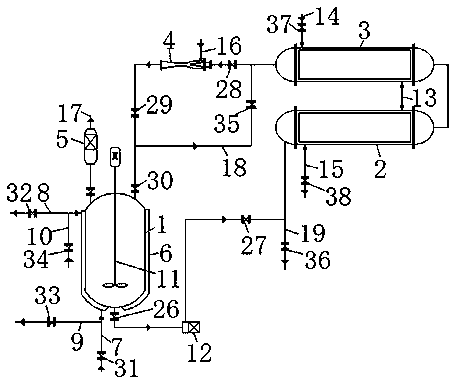

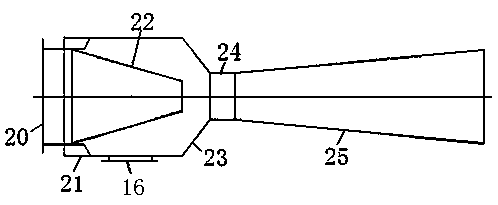

[0012] Such as figure 1 with figure 2 Shown, a kind of utilization high boiling point solvent absorption VOC of the present invention and recycling device, it comprises cooling mixing tank 1, cooler I2, cooler II3 and Venturi mixer 4, they are connected by pipeline, described Venturi The inner mixer 4 comprises a connecting pipe 20, on which a gas suction chamber 21 is arranged, and a conical nozzle 22 is arranged in the gas suction chamber 21 at the junction of the connecting pipe 20 and the gas suction chamber 21, The rear end of the gas suction chamber 21 is provided with a tapered section 23, the tapered section 23 is connected to the throat section 24, the throat section 24 is connected to the diffusion section 25, and the VOC gas source inlet 16 is located in the gas suction chamber. 21, the length ratio of the gas suction chamber 21, tapered s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com