Control method and equipment

A control method and equipment technology, which are applied to kitchen utensils, home utensils, utensils with integral electric heating devices, etc., can solve the problems of easy failure of pressure switches, pressure relief, and affecting the service life of electric pressure cookers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

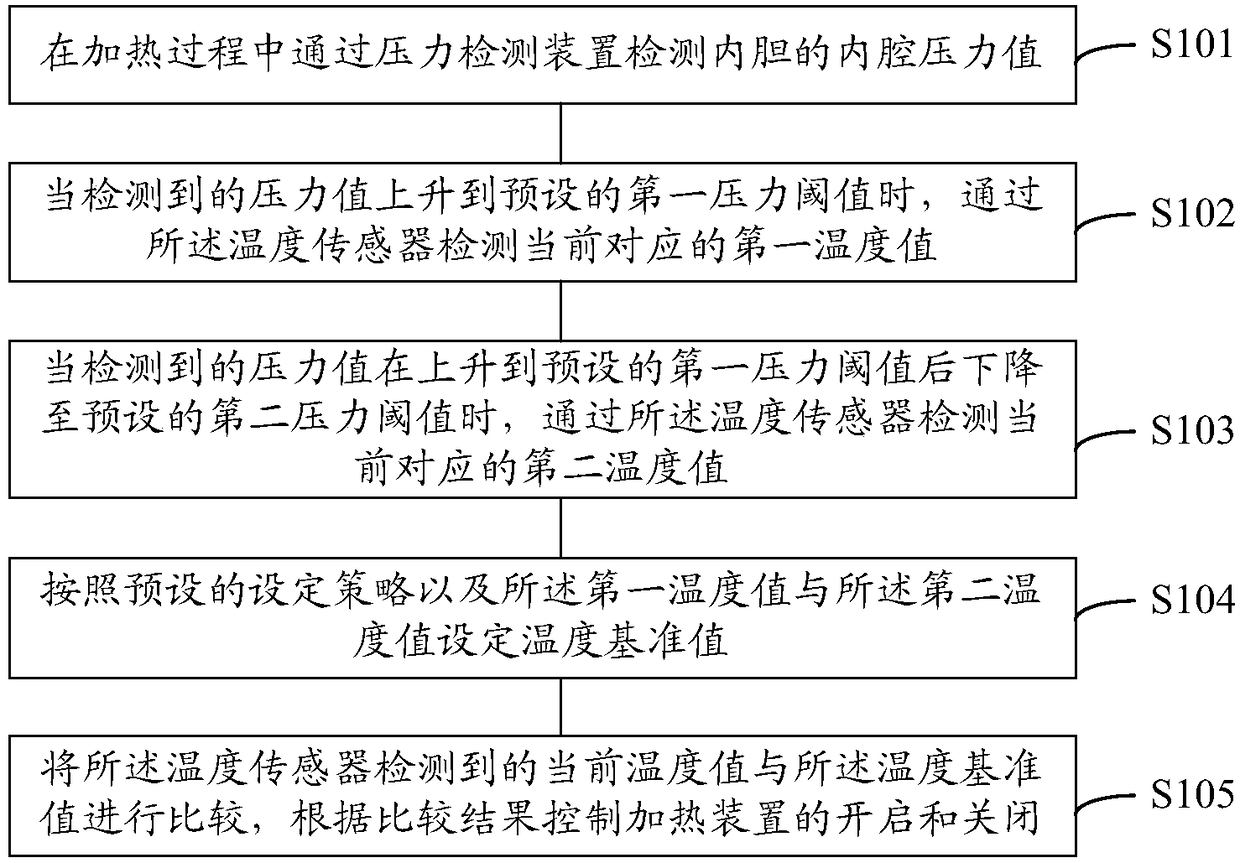

[0030] see figure 1 , which shows a control method provided by an embodiment of the present invention, which can be applied to a cooking device provided with a pressure detection device and a temperature sensor, and the method includes:

[0031] S101: Detect the inner cavity pressure value of the inner tank by the pressure detection device during the heating process;

[0032] S102: When the detected pressure value rises to a preset first pressure threshold, detect the current corresponding first temperature value through the temperature sensor;

[0033] S103: When the detected pressure value rises to the preset first pressure threshold and then drops to the preset second pressure threshold, use the temperature sensor to detect the current corresponding second temperature value;

[0034] S104: Set a temperature reference value according to a preset setting strategy and the first temperature value and the second temperature value;

[0035] S105: Comparing the current temperatu...

Embodiment 2

[0061] Based on the same technical concept as the foregoing embodiments, this embodiment will describe the technical solutions of the foregoing embodiments in detail through the following specific examples. When the pressure value detected by the pressure detection device rises to the first pressure threshold, the heating device will be turned off; and after the heating device is turned off, it will be turned on again when the pressure value detected by the pressure detection device drops to the second pressure threshold The heating device, therefore, during the working process of the cooking device, the pressure value detected by the pressure detection device will rise to the first pressure threshold more than once, and will drop to the second pressure threshold more than once.

example 1

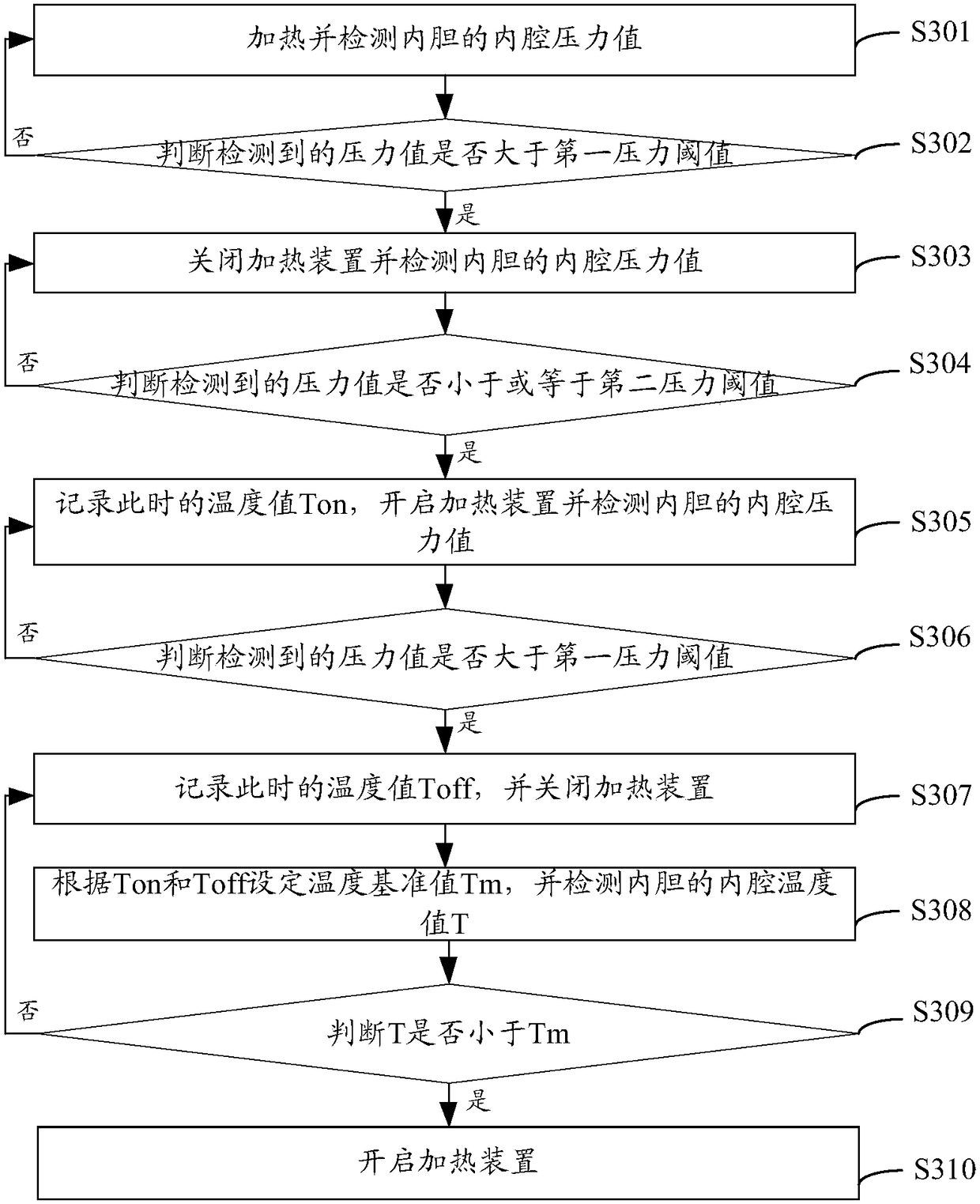

[0063] see image 3 , the specific flow of the control method shown in this example may include:

[0064] S301: heating and detecting the inner cavity pressure value of the inner tank;

[0065] S302: Determine whether the detected pressure value is greater than the first pressure threshold P1; if so, go to S303; otherwise, go to S301 to continue heating and detect the inner cavity pressure value of the inner tank;

[0066] S303: Turn off the heating device and detect the inner cavity pressure value of the inner tank;

[0067] Understandably, when the heating device is turned off, the temperature of the inner tank will gradually decrease, and the pressure value will also decrease accordingly.

[0068] S304: Determine whether the detected pressure value is less than or equal to the second pressure threshold P2; if so, go to S305; otherwise, go to S303 to continue detecting the inner cavity pressure value;

[0069] S305: Record the temperature value Ton at this time, turn on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com