Device for securing a blanket module to a fusion reactor vacuum vessel

A cladding module and reactor technology, applied in fusion reactors, thermonuclear fusion reactors, nuclear reactors, etc., can solve problems such as lack of stoppers, weakened threaded connections, and limited allowable torque values, so as to increase load support capacity and facilitate Installation work, prevent possible impairing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

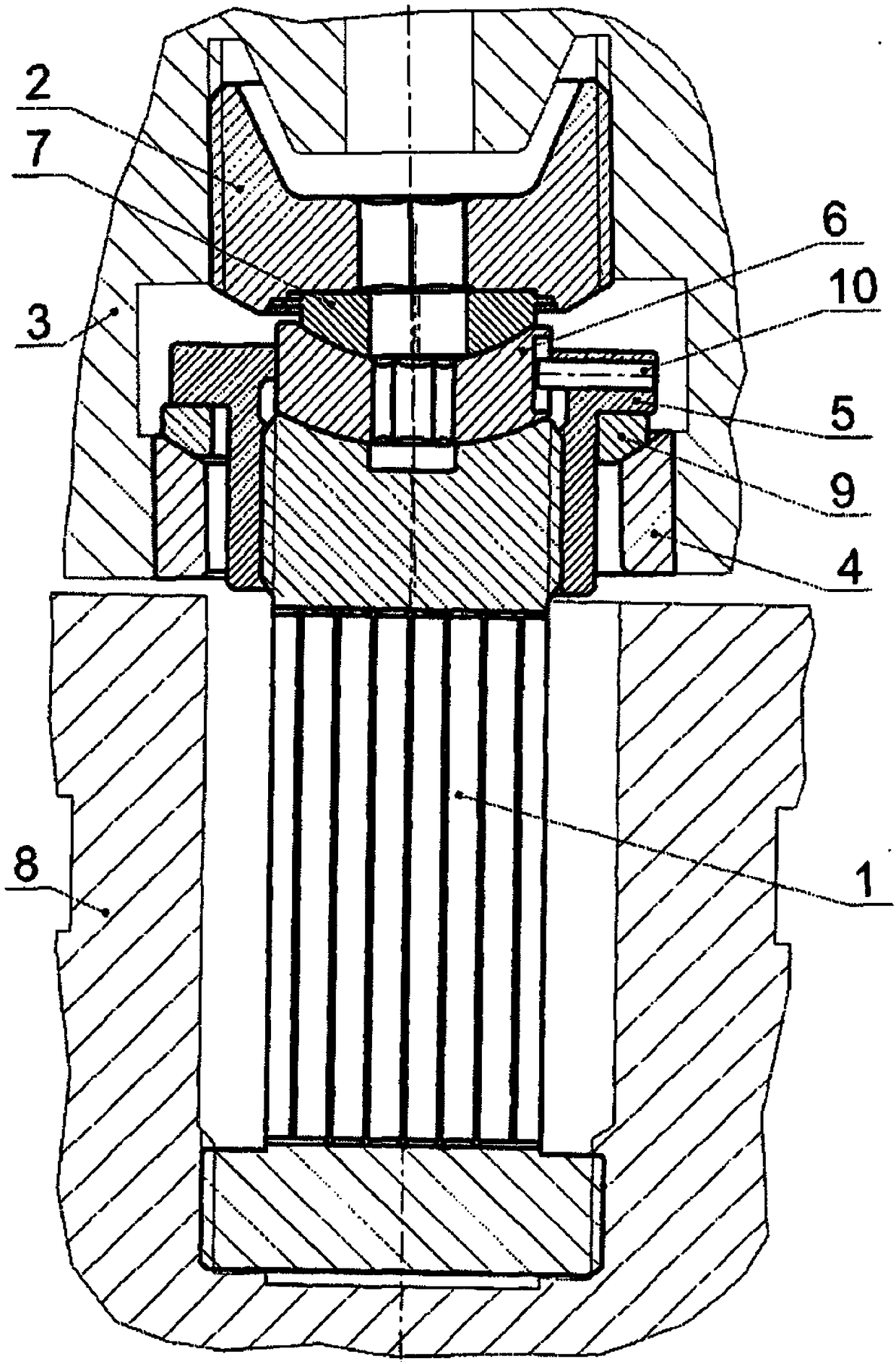

[0024] A device for fixing a cladding module to a fusion reactor vacuum chamber, comprising: a flexible support 1 with a flange, a fastener 2, and a displacement compensation at the flange of the flexible support facing the cladding module 3 The displacement compensator includes a support sleeve 4, a locking screw 5, a spacer sleeve 6, and a coupling sleeve 7 with a spherical protrusion. Said flexible support 1 is made in the shape of a rod, located between two flanges. The flanges of the flexible support 1 are configured with male threads, one of the flanges screwing the flexible support 1 to the vacuum chamber 8; , another flange with a concave spherical end surface couples the flexible support 1 to the cladding module 3 through the displacement compensator. The threaded fastener 2 is configured as a self-locking nut with a male thread. The support sleeve 4 is installed in the installation groove of the cladding module 3 and rigidly fixed with the installation groove havin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com