Method for conveying or transporting fluid or semi-fluid materials with a dual piston pump and the dual piston pump

A double piston pump, technology for conveying fluid, applied in the field of conveying or transporting fluid or semi-fluid materials with a double piston pump and its double piston pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

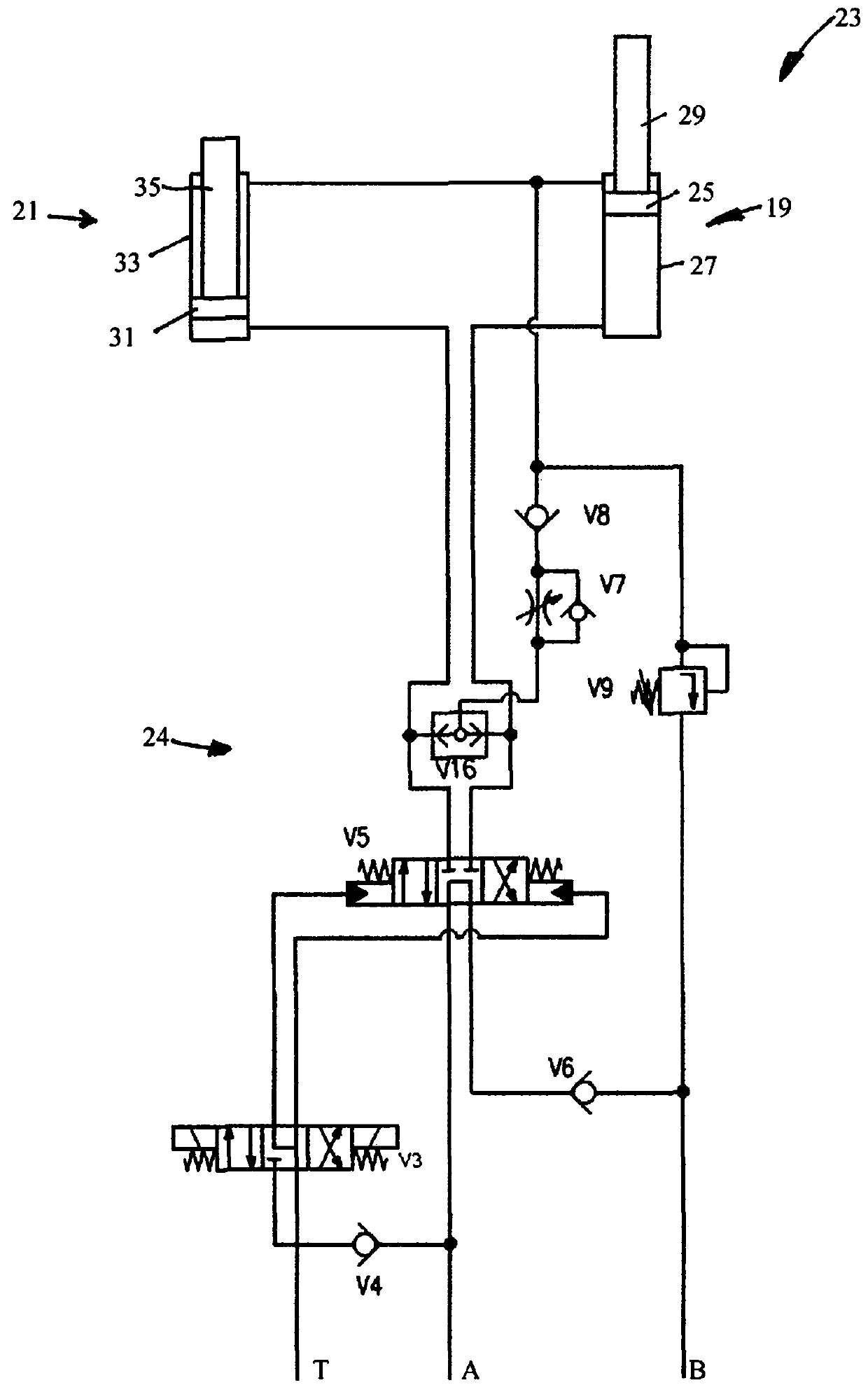

[0034] figure 1 A dual piston pump 1 is shown schematically, the basic configuration of which is known in the art. The dual-piston pump 1 comprises delivery cylinders 3 and 4 in which delivery pistons 5 and 6 are displaceable, respectively. The double piston pump 1 comprises a feed hopper 7 comprising a housing 10 on the rear side of which a rear plate 8 is arranged. The material to be dispensed by the double piston pump 1 is fed into the feed hopper 7 according to the feed arrow A9 . figure 1 The material fed into the feed hopper 7 is not shown.

[0035]On the rear plate 8 is fixed a transfer pipe system (S-Weiche) 13 comprising a transfer pipe 14 which will be connected alternately to the opening 11 connected to the delivery cylinder 3 and to the delivery cylinder 4 Connected opening 12 . According to the double arrow 16 , the transfer tube 14 is turned between the opening 11 and the opening 12 by means of a turning lever 15 which is formed part of an articulation 17 fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com