Method and device for injecting micro-nano bubbles into toilet tank

A technology of micro-nano bubbles and toilets, applied in water supply devices, mixing methods, transportation and packaging, etc., can solve the problems of low concentration of fine bubbles, reduce the amount of flushing water, and adverse effects, so as to improve the concentration and residence time of bubbles and avoid loss and waste of energy consumption, reducing the effect of flushing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

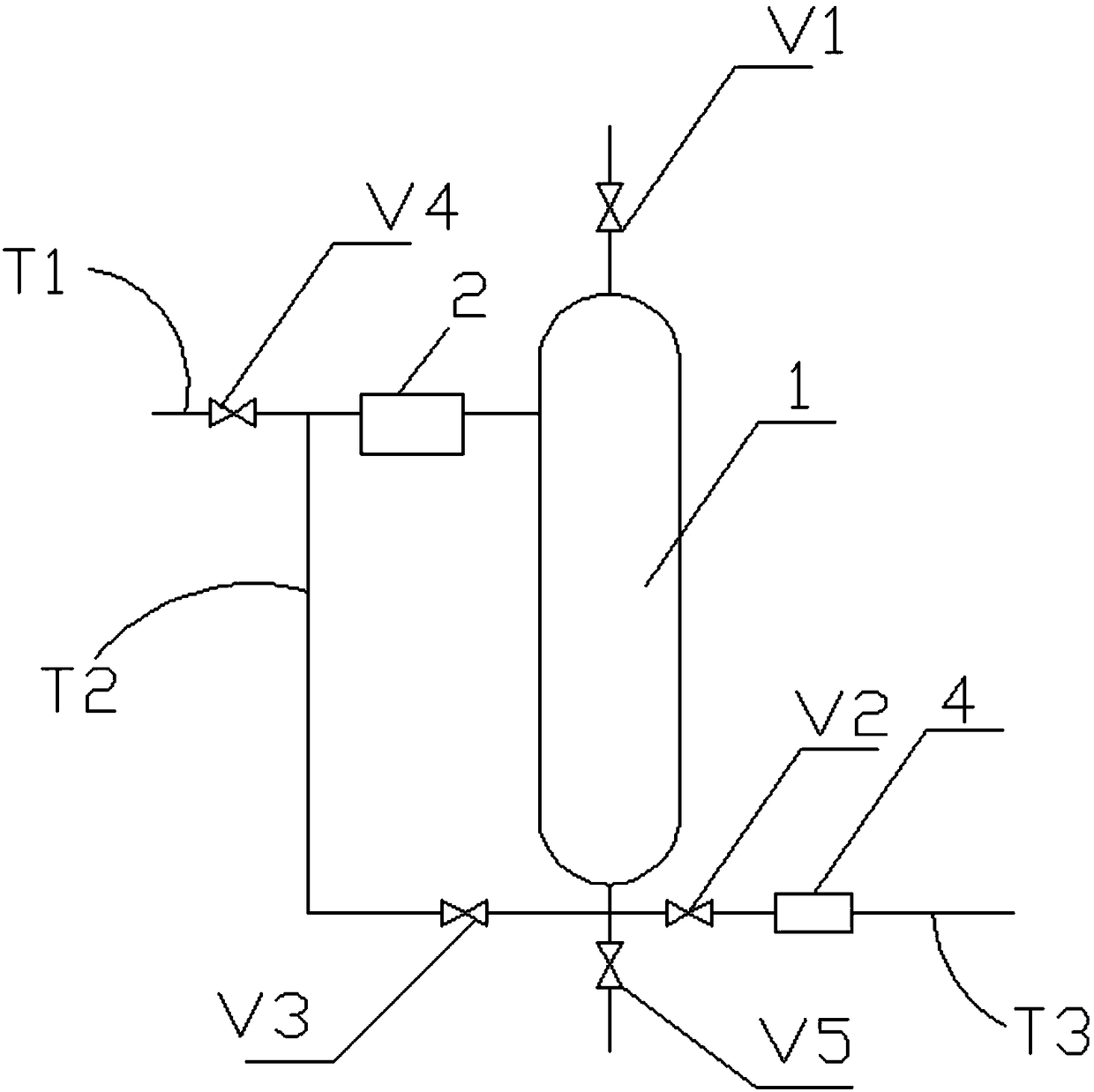

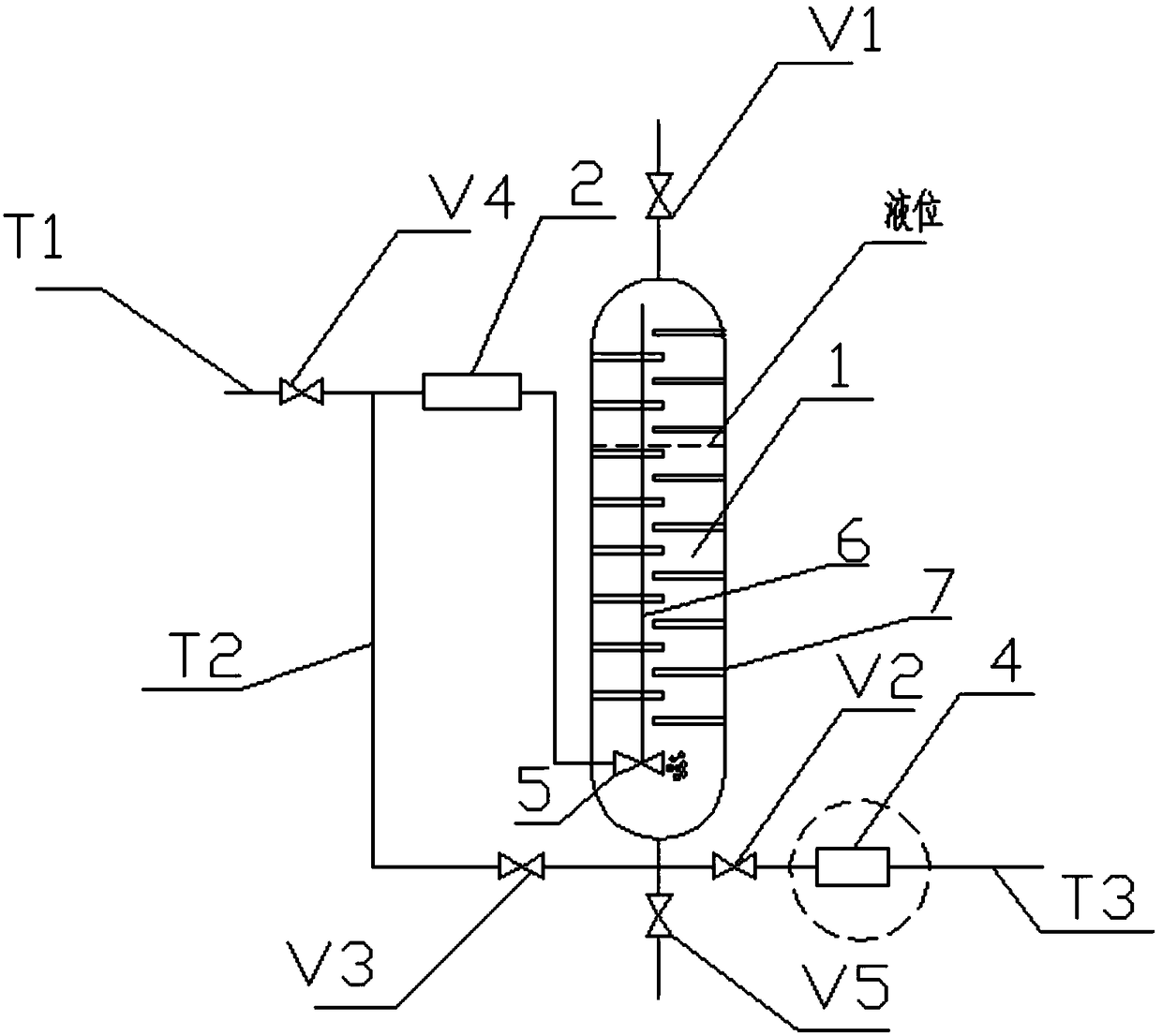

[0042] see figure 2 , the whole device includes solenoid valves V1-V5, toilet water inlet pipeline T1, water pump 2, hollow cavity 1, bubble releaser 4, ejector 5, air duct 6, flap 7.

[0043] Wherein, the water inlet pipe T1 communicates with the jet device 5 at the lower part of the hollow cavity body 1 through the water pump 2, and the jet device 5 is connected with the air guide tube 6, and the air guide tube 6 is arranged inside the hollow cavity body 1 from bottom to top; A plurality of folded plates 7 are arranged at intervals on the side, and the folded plates 7 are used for turbulence; the lower part of the hollow cavity 1 is connected with the water inlet pipe T1 through the mixing circulation pipe T2; the lower part of the hollow cavity 1 is also directly connected with the toilet bowl through the release pipe T3, A bubble releaser 4 is provided on the release pipe T3; a water pump 2 is provided on the circulation pipe T2 or on the water inlet pipe T1 between the c...

Embodiment 2

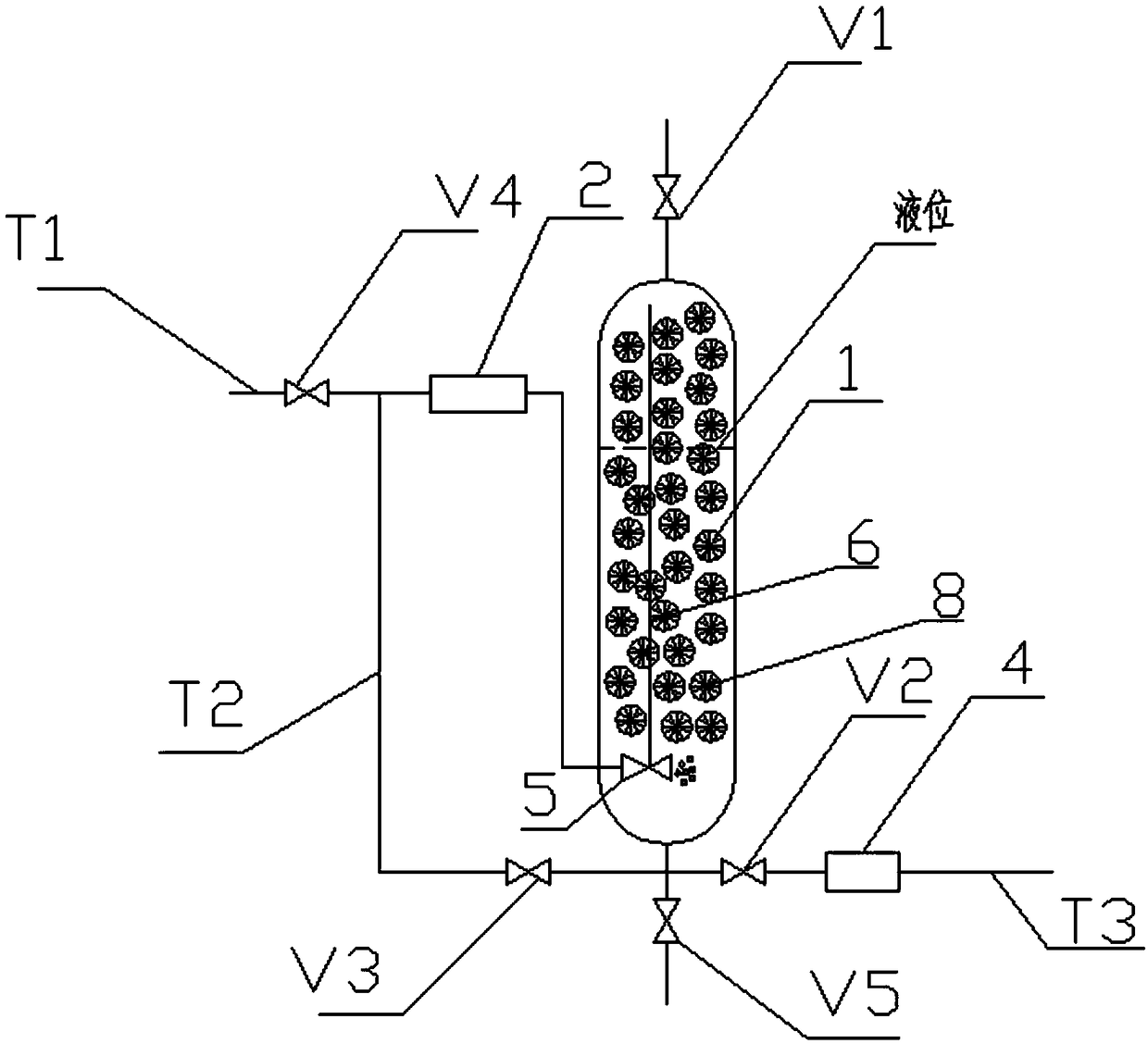

[0058] see image 3 , The hollow cavity 1 of this embodiment is provided with a filler 8, and the filler 8 is used to increase the gas-liquid contact time and contact area. Wherein, the folded plate 7 is not shown in the figure, and the folded plate 7 may or may not be present.

[0059] The rest of the structure is the same as the embodiment, and the implementation steps are the same as the embodiment.

Embodiment 3

[0061] see Figure 4 , the whole device includes solenoid valves V1-V5, toilet water inlet pipeline T1, water pump 2, hollow cavity 1, bubble releaser 4, ejector 5, nozzle 9, and guide tube 10.

[0062] Among them, the water inlet pipe T1 communicates with the nozzle 9 in the hollow cavity 1 through the water pump 2, the nozzle 9 is located above the liquid surface, and the spraying direction is downward; the hollow cavity 1 is provided with a guide tube 10; The tube T2 is connected with the water inlet pipe T1; the lower part of the hollow cavity 1 is also directly connected with the toilet bowl through the release pipe T3, and the release pipe T3 is provided with a bubble releaser 4; the circulation pipe T2, or the water inlet pipe T1 is interposed between the circulation pipe The part between T2 and the hollow cavity 1 is provided with a water pump 2; the hollow cavity 1 is provided with a solenoid valve V1; the water inlet pipe T1, the mixing circulation pipe T2, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com