Segmental cantilever assembly pier capping beam and assembling method thereof

A section and cover beam technology, applied in the erection/assembly of bridges, bridges, bridge parts, etc., can solve problems such as adverse effects on bridge safety and durability, increase in length and self-weight of cover beams, and impact on cover beam hoisting construction, etc. Achieve the effect of reducing construction difficulty and risk construction risk, simple and fast construction, and easy quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below according to the accompanying drawings and specific embodiments of the present invention.

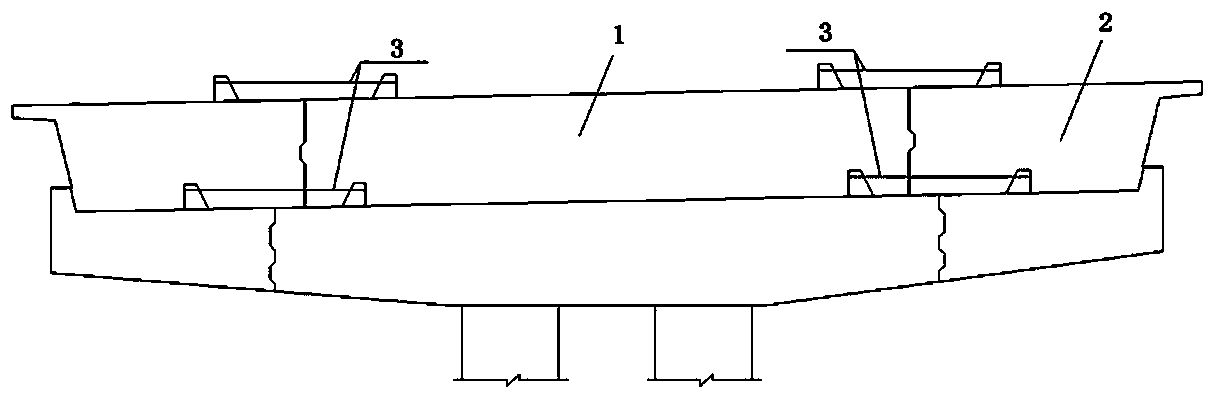

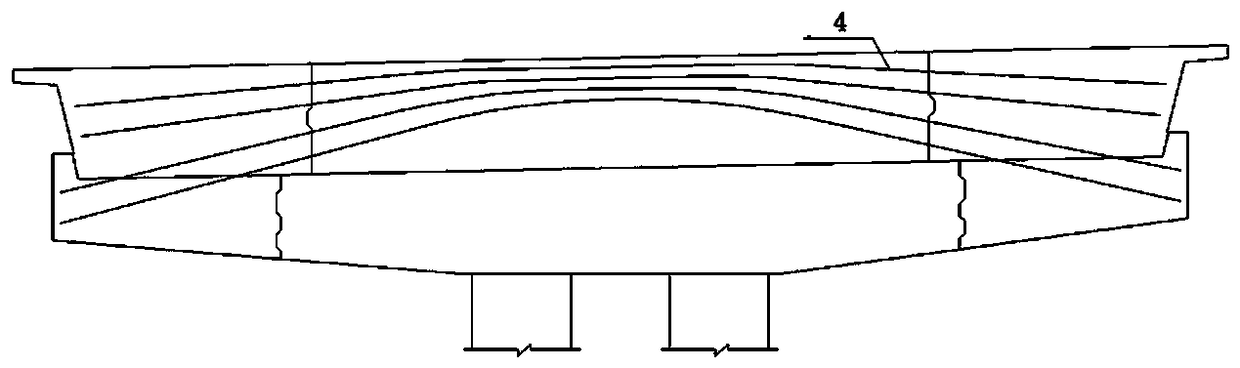

[0033] The figure includes: fulcrum segment 1, cantilever segment 2, temporary prestressed reinforcement 3, and permanent prestressed reinforcement 4.

[0034] As shown in the figure, a segmental cantilever assembled pier cover girder is characterized in that the cover girder is spliced by several prefabricated cover beam segments along the length of the cover girder, and the joints between adjacent prefabricated cover beam segments The form is a corbel-type vertical seam, the corbel-type vertical seam includes a vertical seam and a horizontal seam, shear keys are provided on the end faces of the cover beam segments on both sides of the seam, and the prefabricated cover beam The end faces of the segments are coated with epoxy adhesive, and the adjacent prefabricated segments are bonded by epoxy adhesive.

[0035] As shown...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com