A pickling-free process of folding in half for the processing of turn signal contact pieces

A contact sheet and turn signal technology, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve problems such as easy deflection of folding lines, collision of bending sharp corners, increase of process steps, etc., to ensure structural stability and installation firmness, reducing half-fold deviation, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

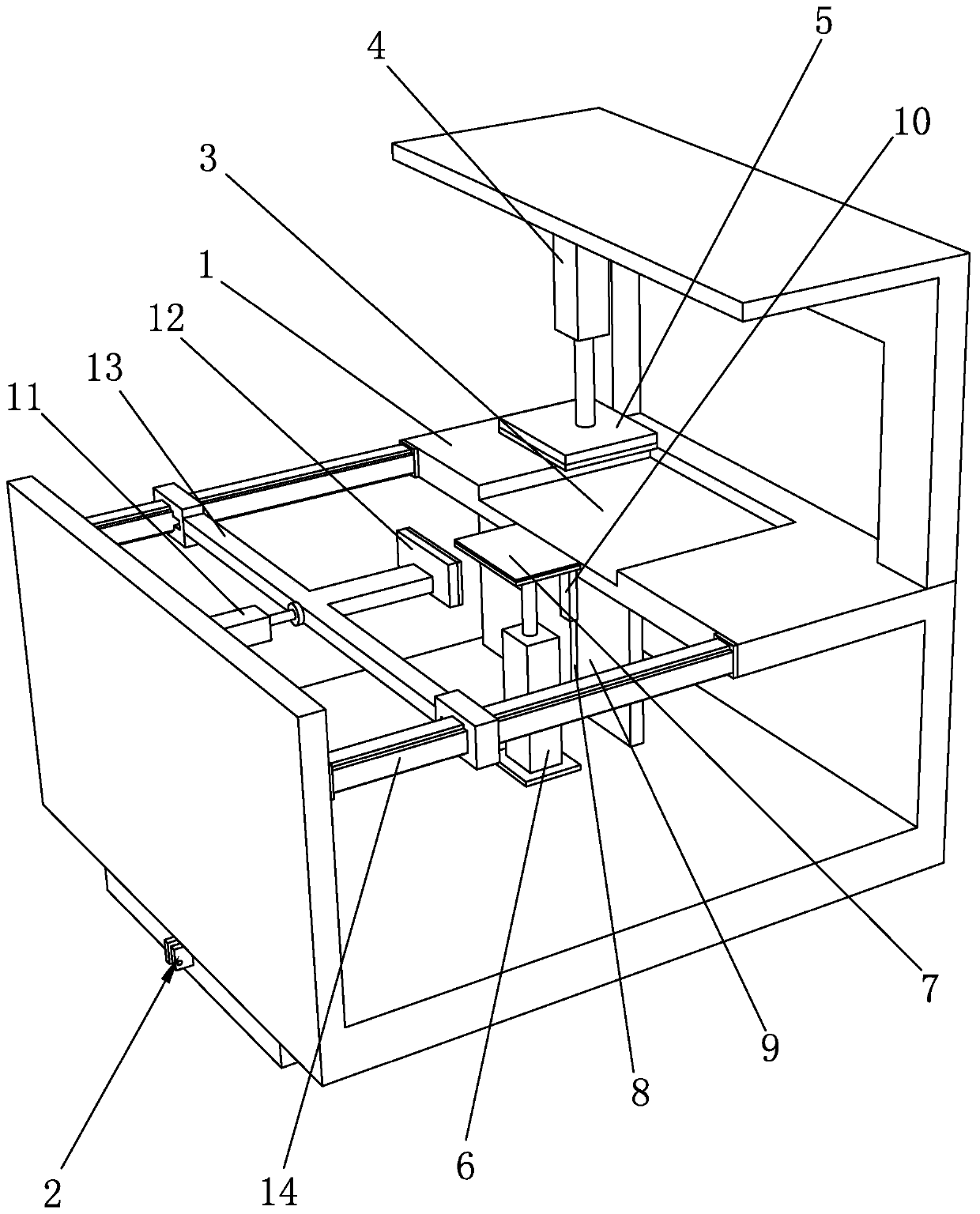

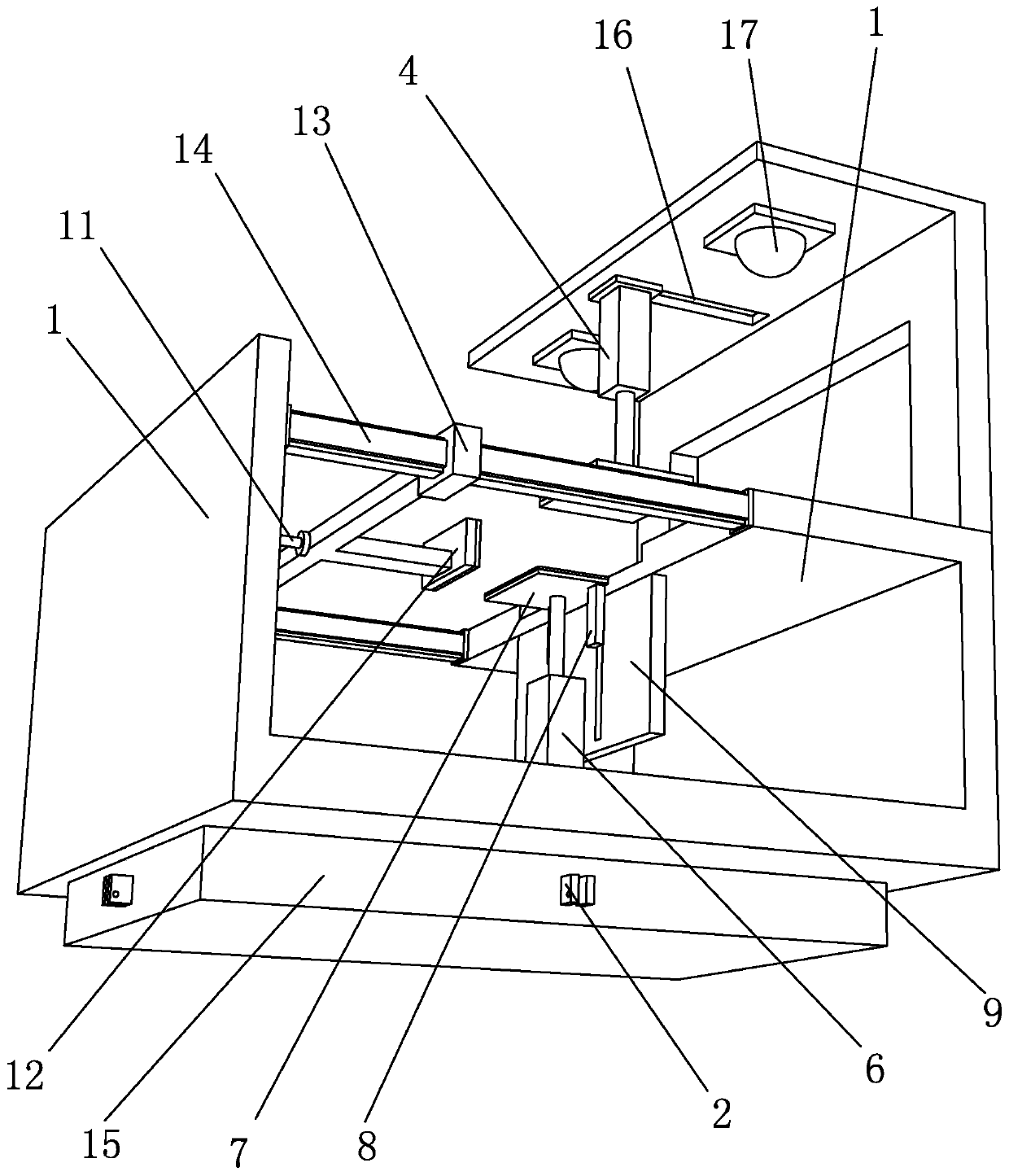

[0031] Such as figure 1 and figure 2 As shown, it is a half-fold pickling-free process for the processing of the turn signal contact sheet of the present invention, which includes the following steps:

[0032] (1) Mold processing and forming:

[0033] a. First, select the corresponding processing mold according to the design size of the turn signal contact piece, install the processing mold on the stamping machine, and perform one-time stamping processing to form the turn signal contact piece. Design drawings, use testing tools to verify the structural size and structural shape of the product, and the products that meet the design requirements enter the subsequent processing;

[0034]b. Then, according to the design drawings, determine the half-folded position on the contact sheet of the turn signal, and carry out structural inspection on the half-folded position, determine the sharp corner of the bend existing at the half-folded position, and delete the sharp corner, and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com