Positioning device for tempered glass production stamping

A technology for stamping and tempering glass, which is applied in the pressing of glass, forming of glass, and re-forming of glass. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

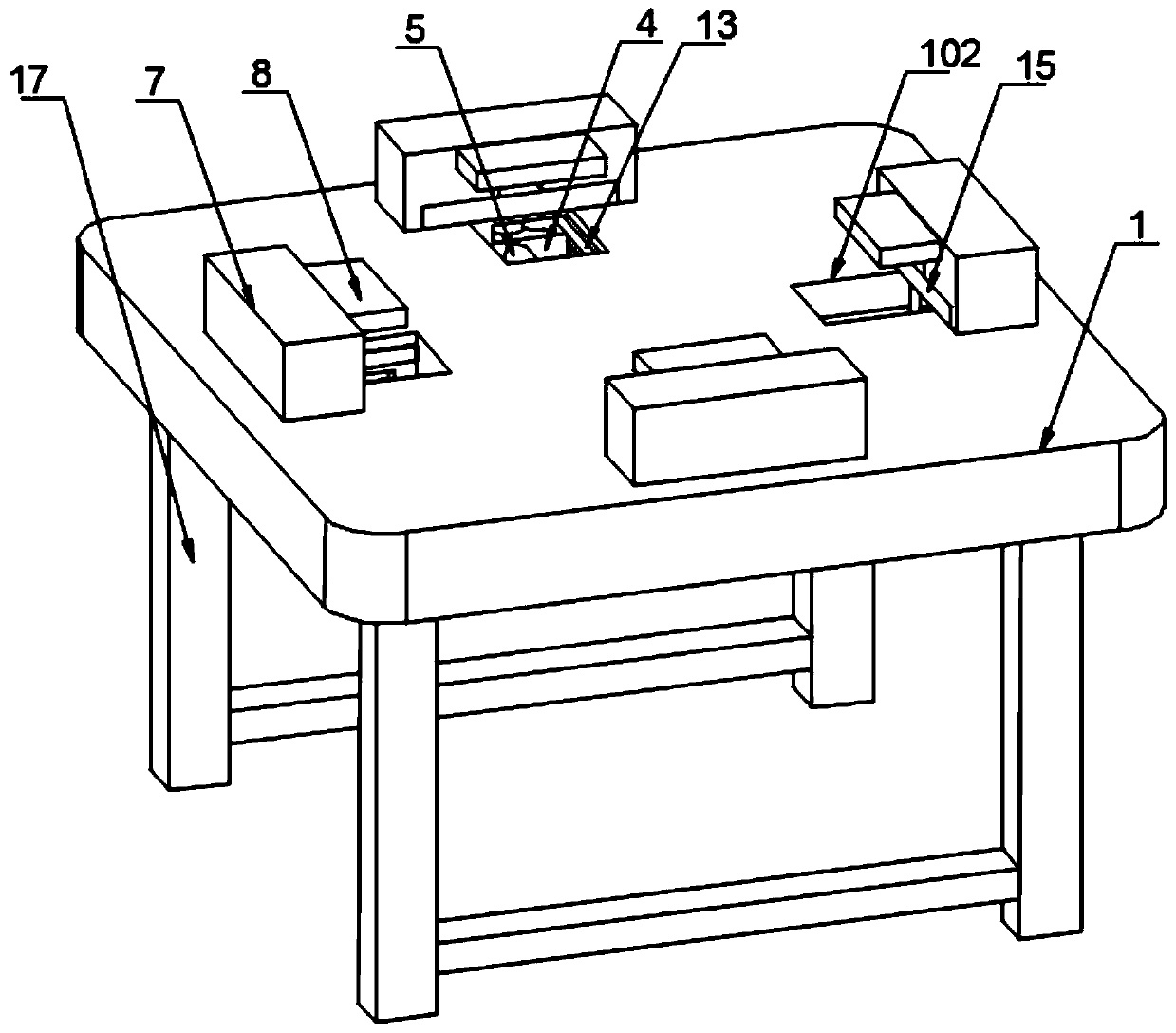

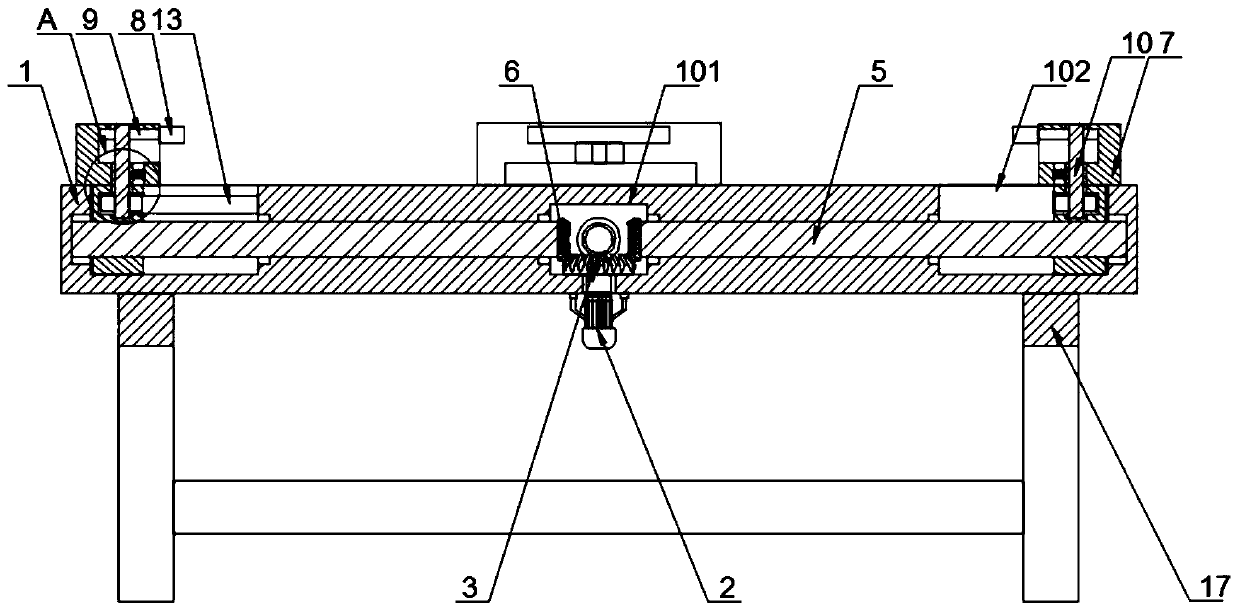

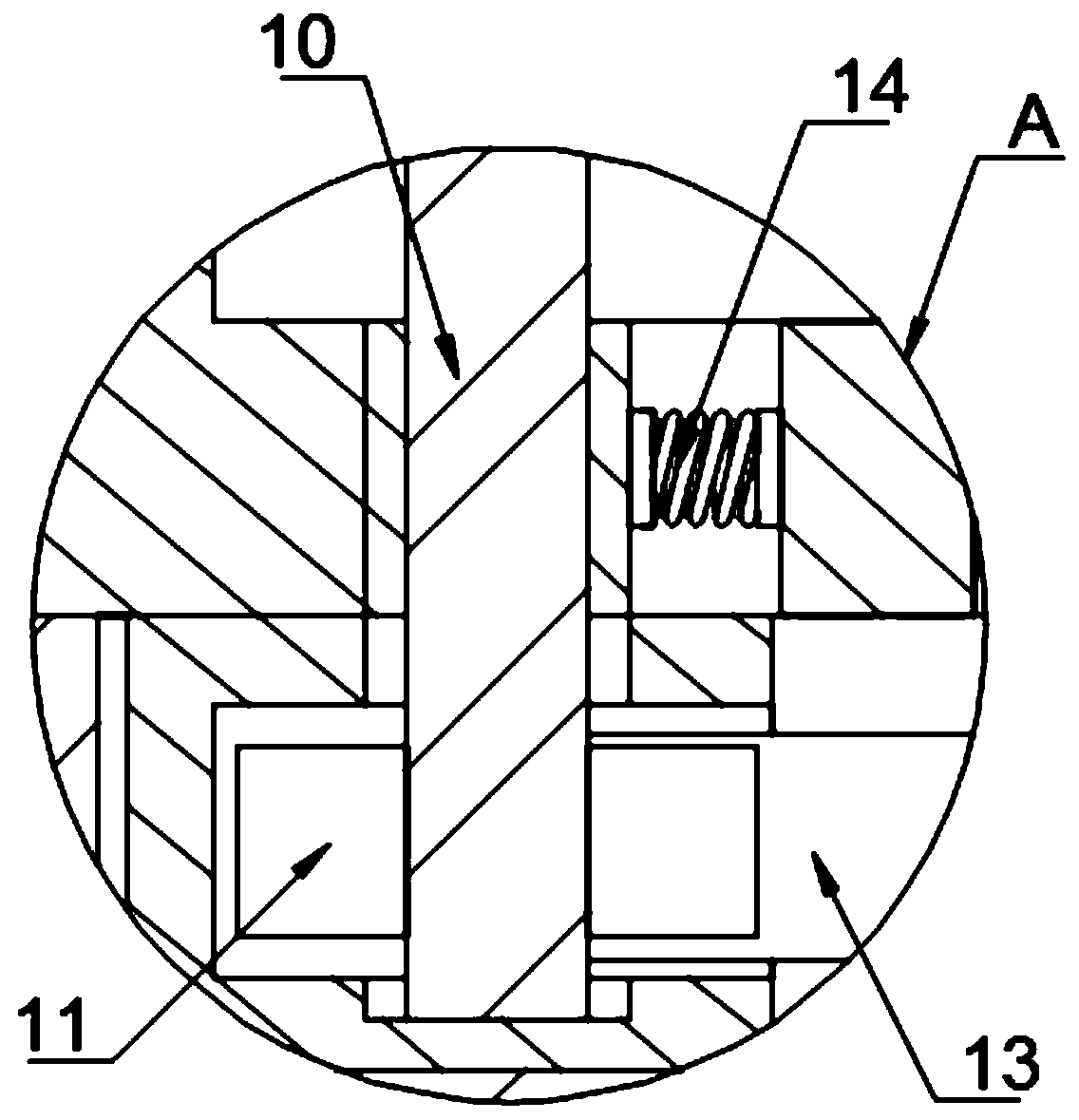

[0028] Refer to the attached figure 1 , figure 2 , image 3 and Image 6 , a positioning device for stamping processing of tempered glass production in this embodiment, comprising a base 1, a positioning mechanism is provided on the top of the base 1, and the bottom end of the positioning mechanism extends to the inside of the base 1;

[0029] The positioning mechanism includes a motor 2, the motor 2 is fixedly connected to the bottom of the base 1, a cavity 101 is provided inside the base 1, the top of the output shaft of the motor 2 extends to the inside of the cavity 101, and the output shaft of the motor 2 The first bevel gear 3 is fixedly connected, and the top of the base 1 is provided with four positioning components, and the four positioning components all include rectangular grooves 102, and the four rectangular grooves 102 are all opened on the top surface of the base 1, and the four positioning components The rectangular slots 102 are uniformly distributed outsi...

Embodiment 2

[0039] Refer to the attached figure 1 , Figure 4 , Figure 5 and Image 6 The difference from Example 1 is that the buffer assembly includes an air bag ring 18 and a rubber plate 19, and the four rubber plates 19 are respectively embedded in the inner surfaces of the four positioning seats 7, and the air bag ring 18 is located on the rubber plate 19 and the inner side of the positioning seat 7, the two sides of the air bag ring 18 are respectively fixedly connected with the rubber plate 19 and the positioning seat 7.

[0040] The specific implementation scenario is: when the four positioning seats 7 are close to the placed glass at the same time, and when the glass is clamped and fastened, the rubber plate 19 will squeeze the airbag ring 18 when the extrusion pressure is too large, so that the airbag ring 18 shrinks and deforms against the pressure. Cushion absorption is carried out, so as to avoid damage to the glass due to excessive extrusion pressure when it is fixed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com