Preparation method of rod-shaped cadmium sulfide CdS NRs/triptycene polymer NTP novel composite photocatalyst

A technology of triptene and cadmium sulfide, applied in organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve problems such as incomplete research on photocatalytic hydrogen production activity , to achieve the effects of easy control of preparation conditions, simple preparation method and high catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

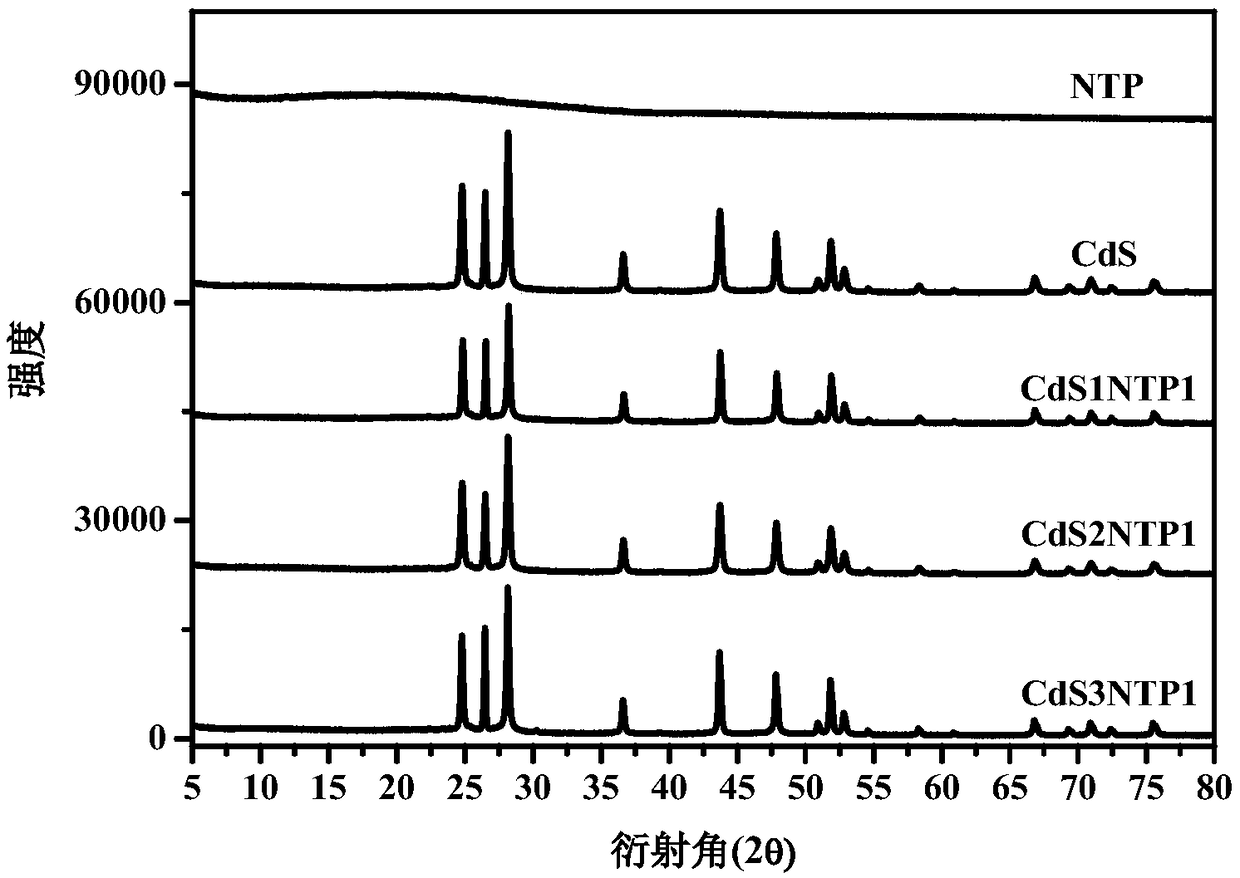

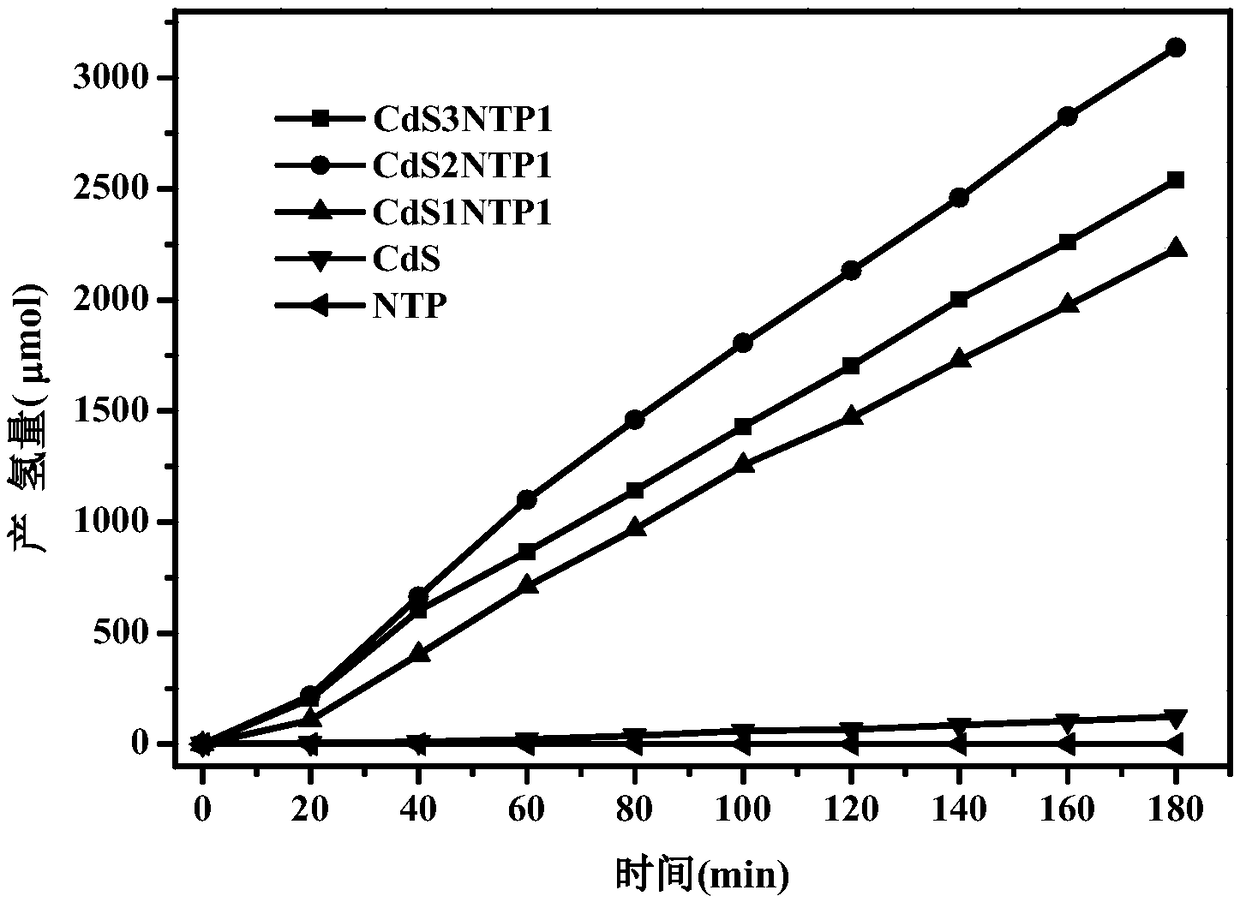

Examples

Embodiment 1

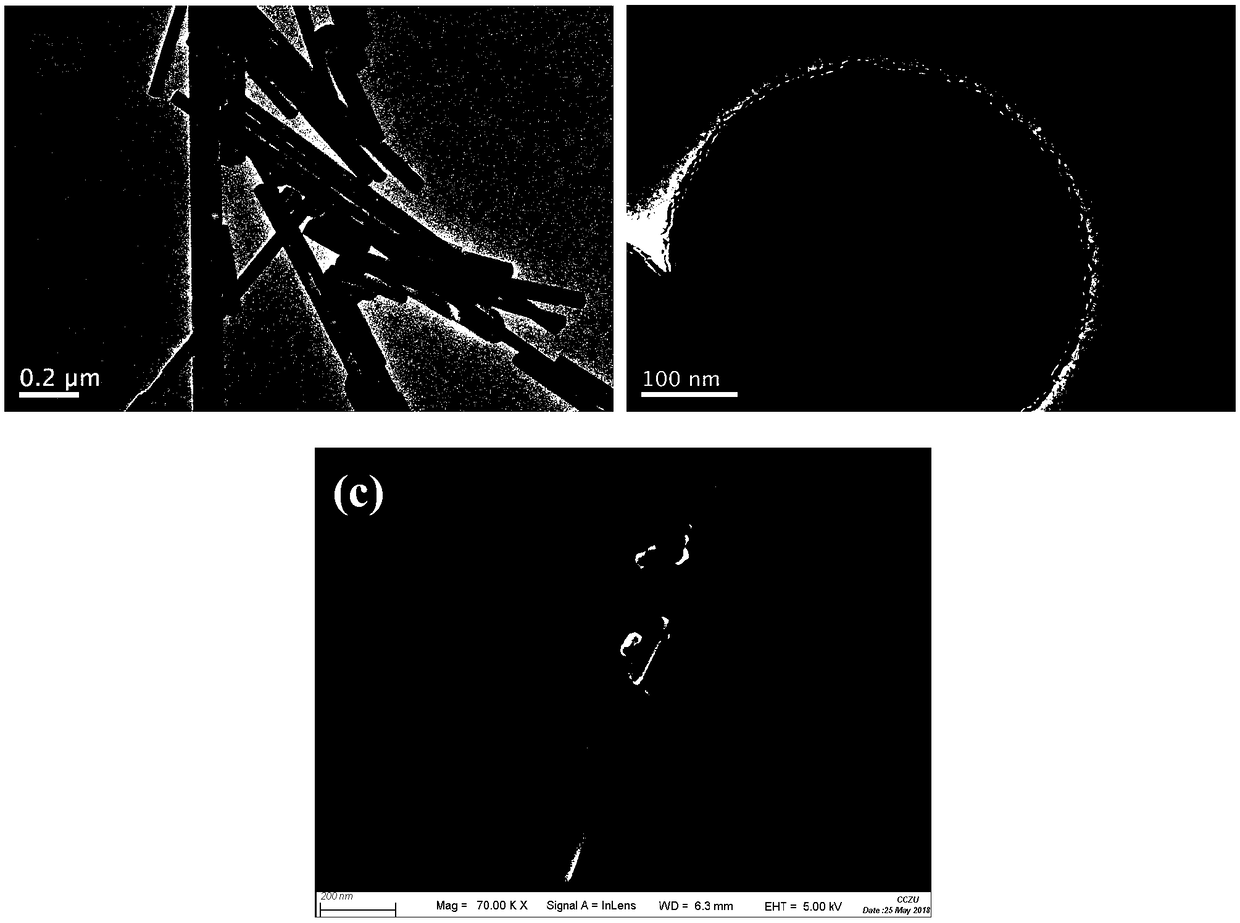

[0030](1) Preparation of rod-shaped cadmium sulfide CdS NRs

[0031] 20.25mmol CdCl 2 2.5H 2 O (4.62g) and 60.75mmol CH 4 N 2 S (4.62g) was added into a 100mL autoclave containing 60mL of ethylenediamine and sealed, and the autoclave was transferred to 160°C for a reaction time of 48h. .Wash the obtained yellow powder with water and ethanol to remove impurities, and centrifugally filter and dry to obtain the product;

[0032] (2) Preparation of NTP

[0033] a: Place triptene (1.25g, 5mmol) in a three-necked flask, add concentrated HNO 3 50 mL, the mixture was heated and stirred at 75° C. for 24 h, and condensed under reflux. The reaction solution was a brown solution, which was cooled to room temperature, then poured into H 2 O (1000 mL) was stirred for 30 min. The precipitate was collected, washed with distilled water, and dried in air. The crude product was purified with dichloromethane / petroleum ether (1:1) as the eluent to give the white solid products 2,6,14-tri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com