Method for manufacturing grooved MOSFET device on basis of two-step microwave plasma oxidation

A technology of microwave plasma and manufacturing method, which is applied in the direction of semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve the problems of poor stability of bottom gate oxide, inability to obtain forward characteristics, and abnormal operation of devices, etc. Achieve the effects of reducing electron defects, increasing effective mobility, and improving oxidation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

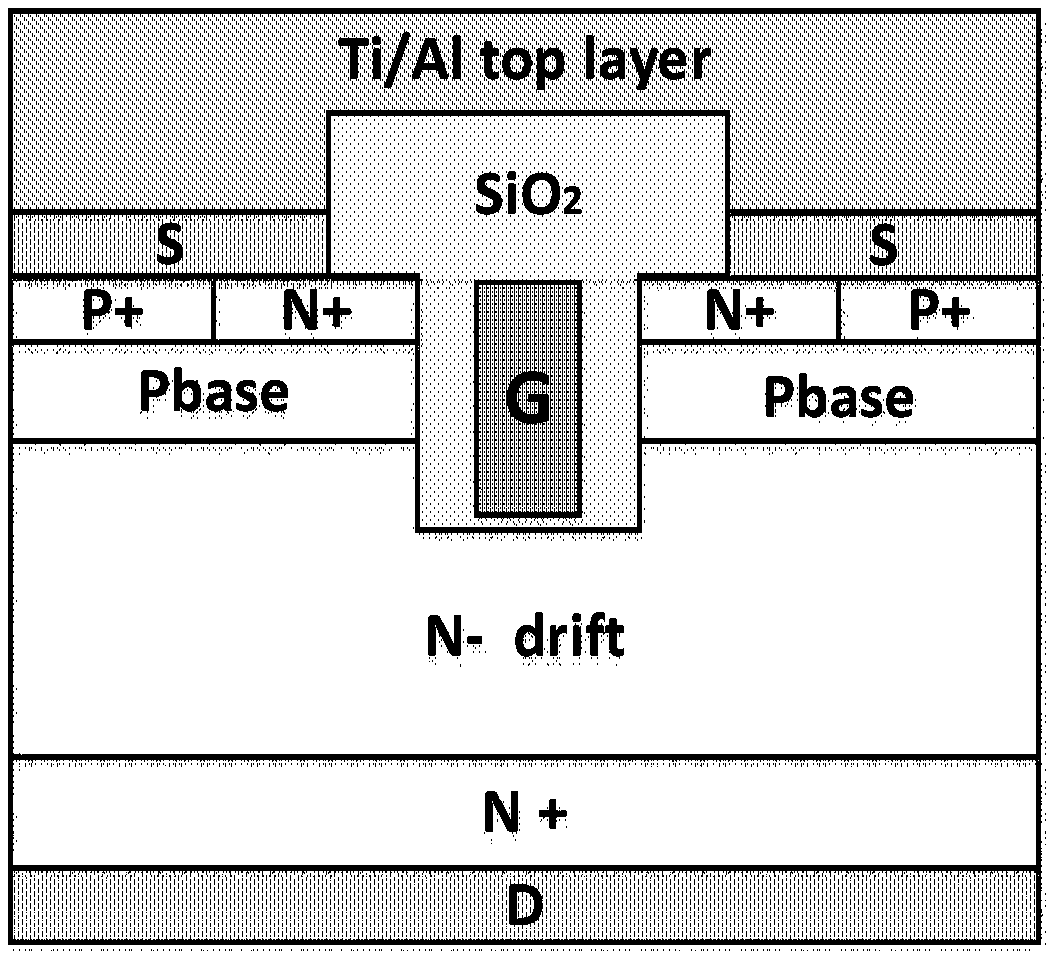

[0060] Such as Figure 4 As shown, the preparation method of the groove MOSFET device generally includes the following steps:

[0061] (1) cleaning the substrate;

[0062] (2) Forming a P-base implantation mask and ion implantation on the substrate;

[0063] (3) Form N-plus mask and ion implantation;

[0064] (4) Forming the P-base and removing the corresponding mask;

[0065] (5) Forming N-plus and removing the corresponding mask;

[0066] (6) Forming a P-plus mask and ion implantation;

[0067] (7) High temperature activation annealing;

[0068] (8) Forming P-plus and removing the corresponding mask;

[0069] (9) forming a groove gate etching mask;

[0070] (10) Groove gate etching;

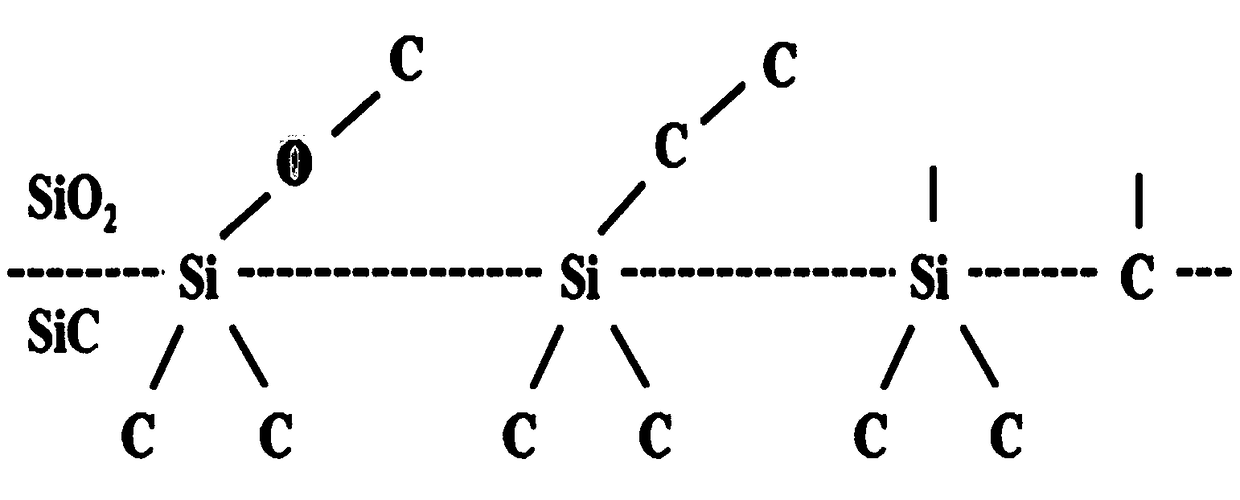

[0071] (11) forming a groove gate oxide layer;

[0072] (12) making a polysilicon gate electrode;

[0073] (13) making the source electrode;

[0074] (14) making the drain electrode;

[0075] (15) making interlayer medium;

[0076] (16) Make the cover metal.

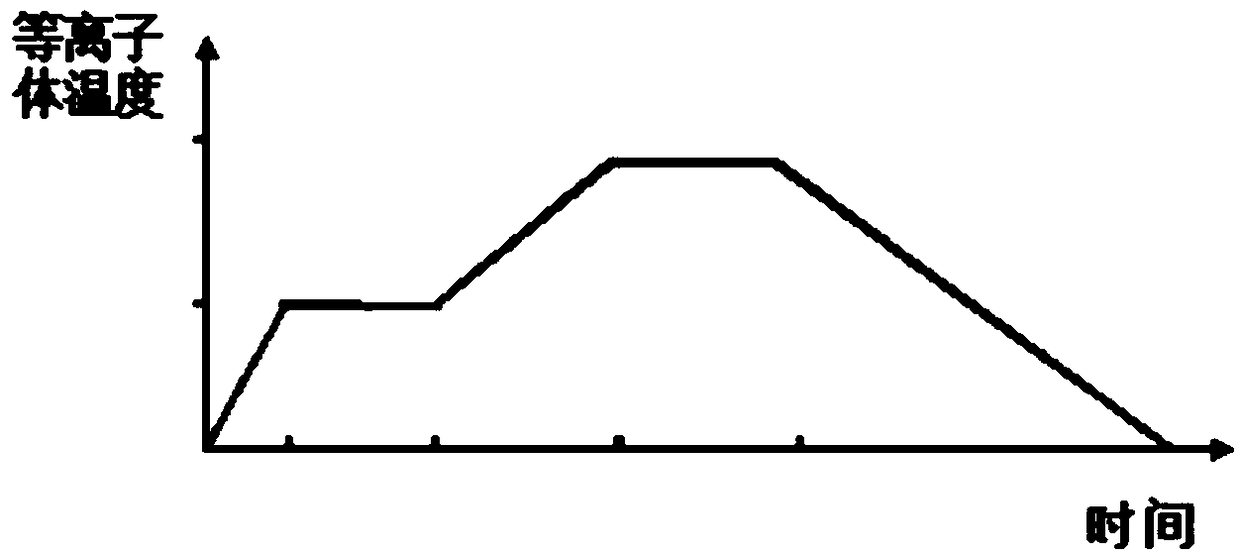

[0077] In this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com