Rectangular optimal layout mixing method based on two stages

A rectangular and phase-based technology, which is applied in the field of plate blanking and layout, can solve the problems of local optimal solution of optimization results and does not have the problem of breaking up and reorganizing plate originals, and achieves the effect of expanding optimization processing and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

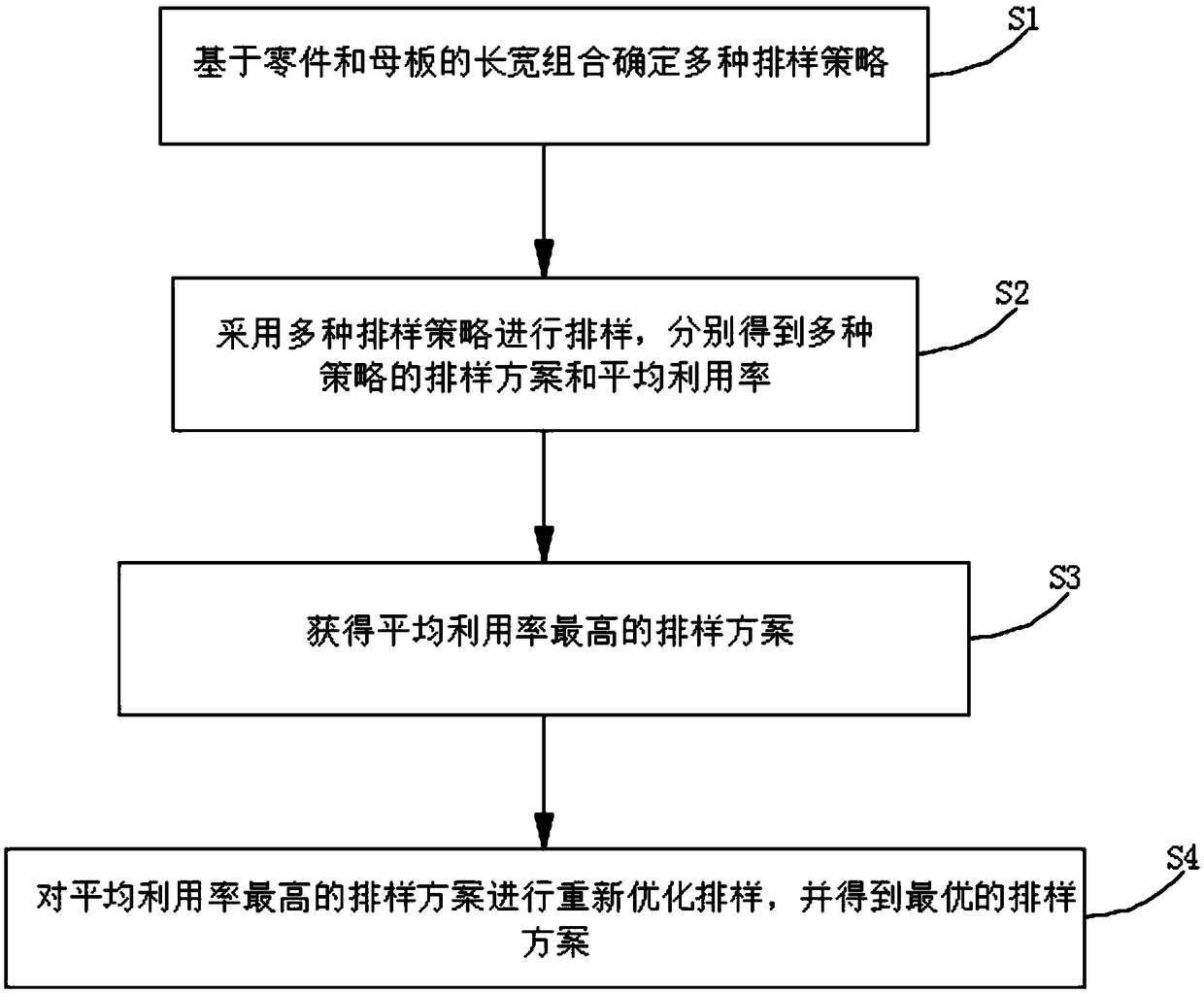

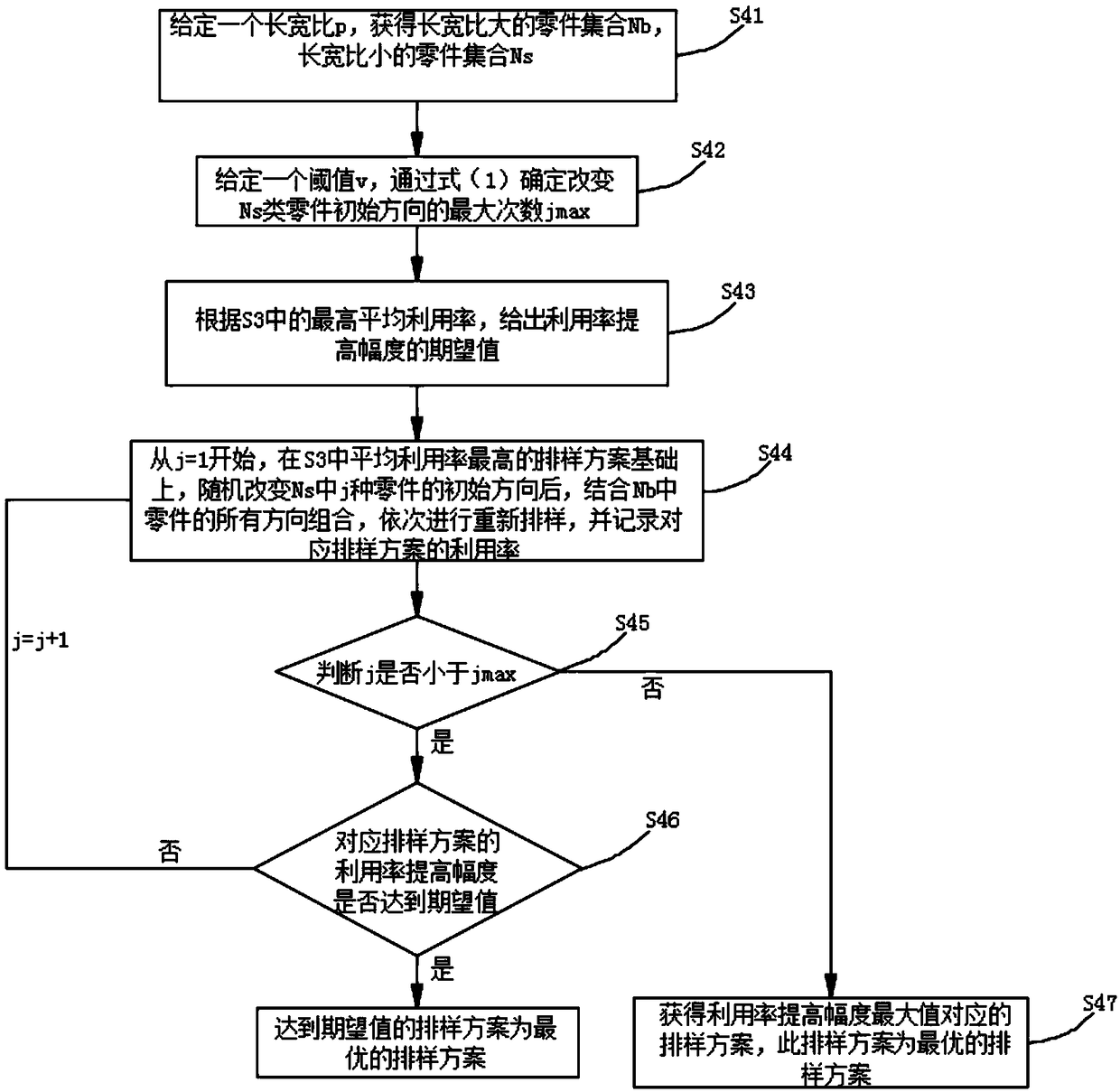

[0042] In the case of considering multiple strategies, the present invention performs rectangular optimized layout, and after obtaining the layout scheme with the highest average utilization rate, optimizes the layout scheme so as to obtain the optimal solution of layout. The specific implementation is used below The method describes the specific process and structure of the present invention in detail.

[0043] Please refer to figure 1 , a two-stage hybrid method based on rectangular optimal nesting, including the following steps:

[0044] S1. Determine multiple layout strategies based on the length and width combinations of parts and motherboards,

[0045] Wherein, there are 4 layout strategies, the 4 strategies are respectively strategy A, strategy B, strategy C and strategy D, strategy A is: overlap and place the longer side of the part and the motherboard on the horizontal line; strategy B is: on the basis of strategy A, rotate the motherboard by 90 degrees; strategy C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com