High-voltage electric display device

A high-voltage live display and display module technology, applied in the direction of indicating the existence of current/voltage, etc., can solve the problems of difficulty in testing electricity and low reliability, and achieve the effects of simple detection operation, improved reliability, and quick maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

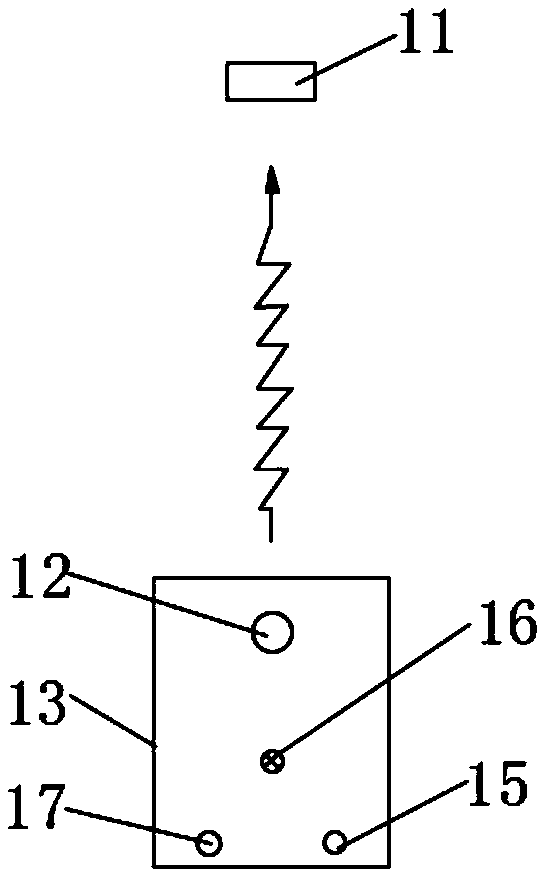

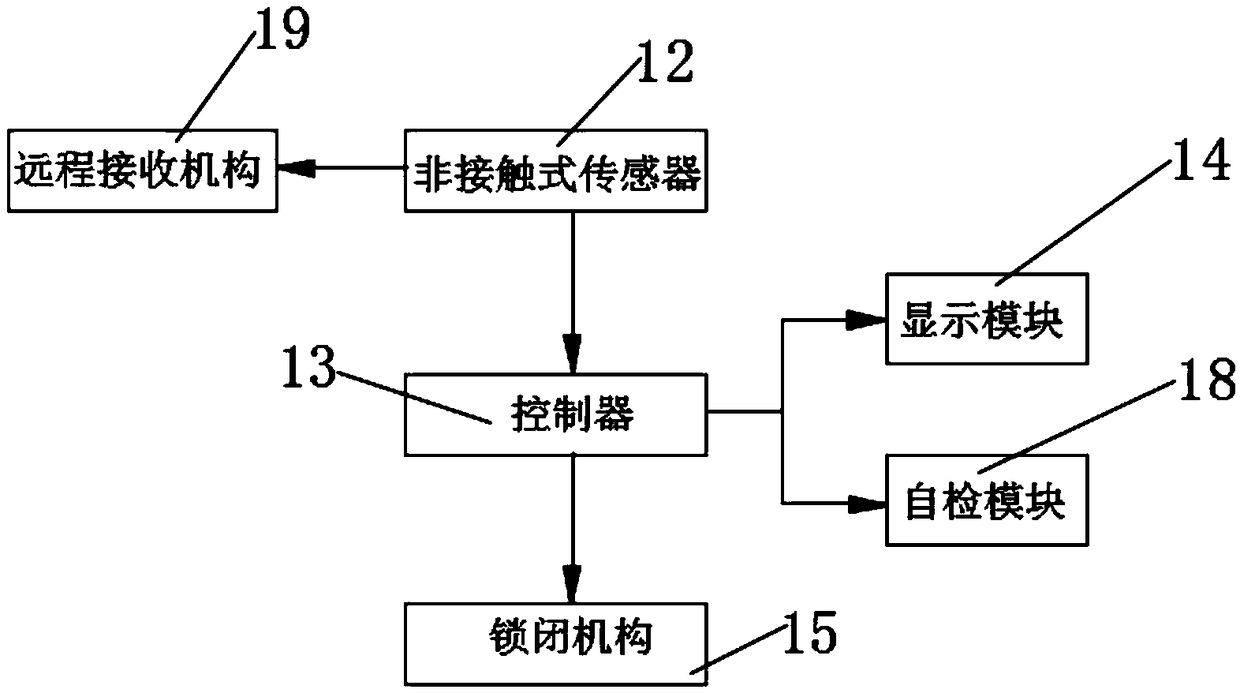

[0030] figure 1 A schematic structural diagram of a high-voltage charged display device 1 provided in Embodiment 1 of the present invention; figure 2 It is a block diagram of the high-voltage charging display device 1 provided by Embodiment 1 of the present invention.

[0031] Such as Figure 1-2 As shown, the high-voltage charged display device 1 provided by the present invention includes a non-contact sensor 12 and a controller 13; the non-contact sensor 12 is connected to the controller 13, and the non-contact sensor 12 is used for non-contact The electrical property of the charged body 11 is measured by means of a method; the controller 13 includes a display module 14, and the display module 14 is used to display the detection result of the non-contact sensor 12.

[0032] The non-contact sensor 12 is connected with the controller 13, and the non-contact sensor 12 measures the electrical property of the charged body 11, and the display module 14 can quickly display the r...

Embodiment 2

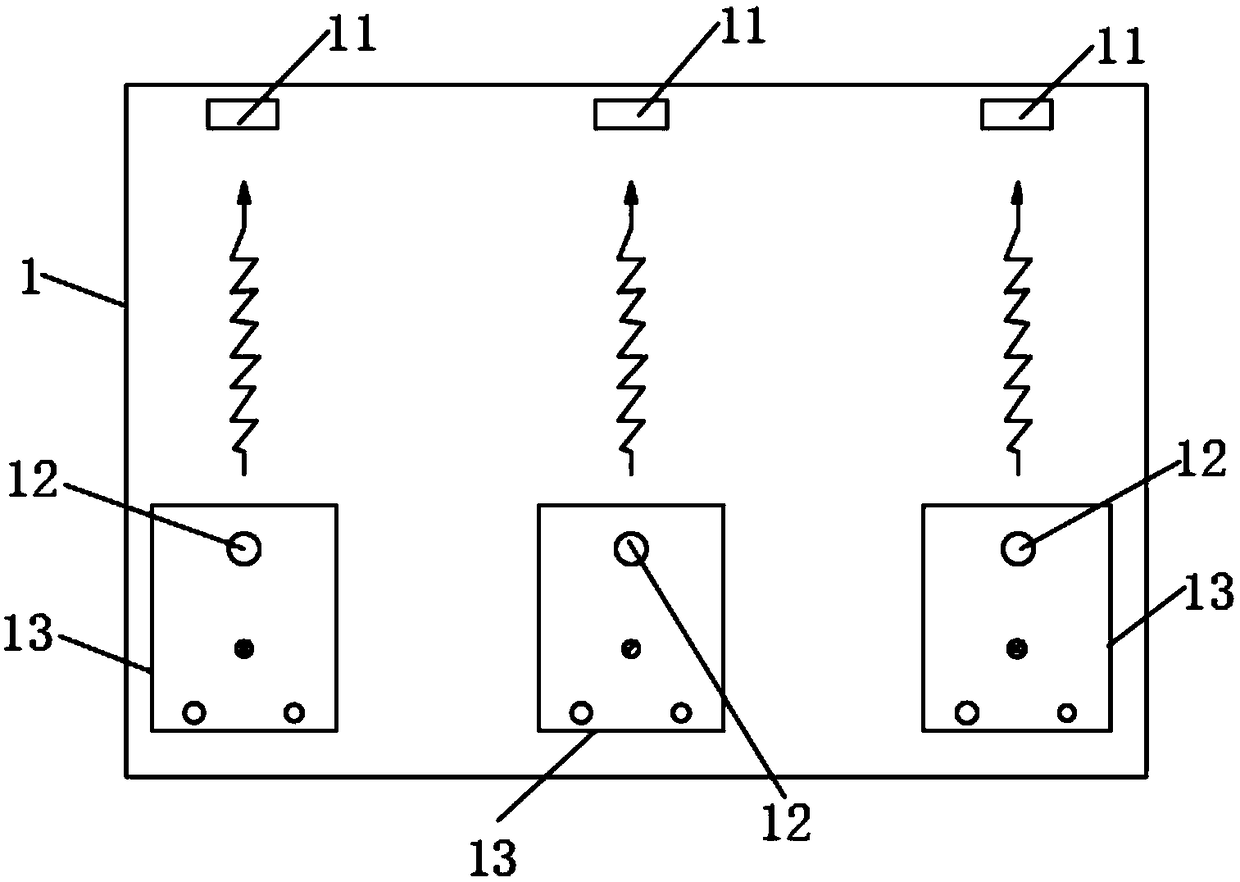

[0053] image 3 It is a schematic structural diagram of the high-voltage charged display device 1 provided by Embodiment 2 of the present invention.

[0054] Such as image 3 As shown, in this embodiment, the difference between the high-voltage charging display device 1 and the embodiment 1 is that the high-voltage charging display device 1 includes three non-contact sensors 12 and three controllers 13; each of the The non-contact sensors are respectively connected to the corresponding controllers 13, and each of the non-contact sensors 12 is used to measure the corresponding circuits, so that the three-phase circuits in the high-voltage charged display device are separately measured.

[0055] Each touch sensor is connected with the corresponding controller 13, and each contact sensor is used to detect the corresponding circuit, so that the three circuits in the switch are separately detected; by being provided with three non-contact sensors 12 and three A controller 13, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com