Optical pulse sensor of intelligent water meter

A smart water meter and sensor technology, applied in the direction of instruments, measuring devices, measuring flow/mass flow, etc., can solve the problems of high-frequency scanning, high power consumption, high power consumption of water meter sensors, and increased pointer rotation resistance. Effective sensing area, reduced overall operating power consumption, and reduced operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

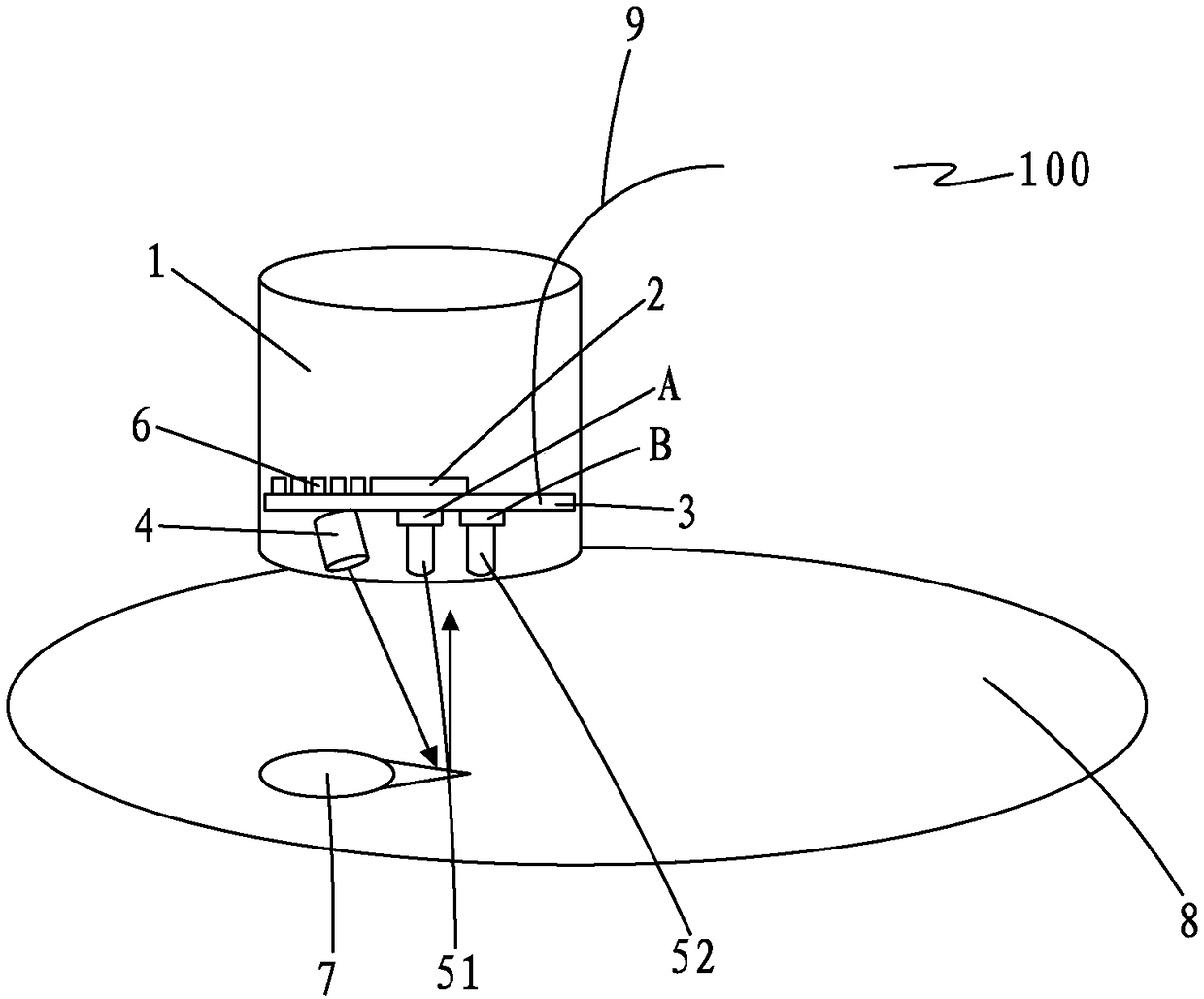

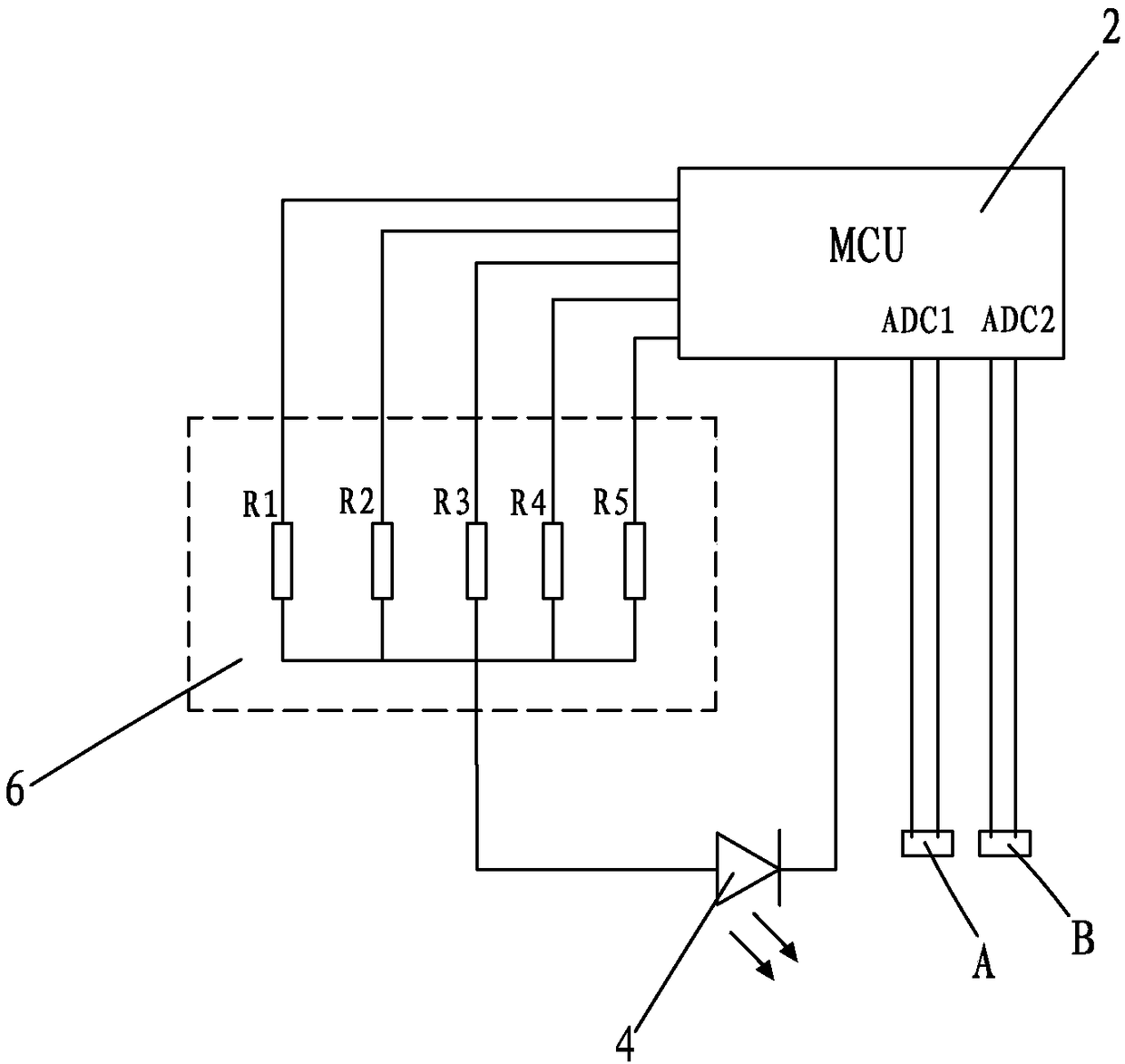

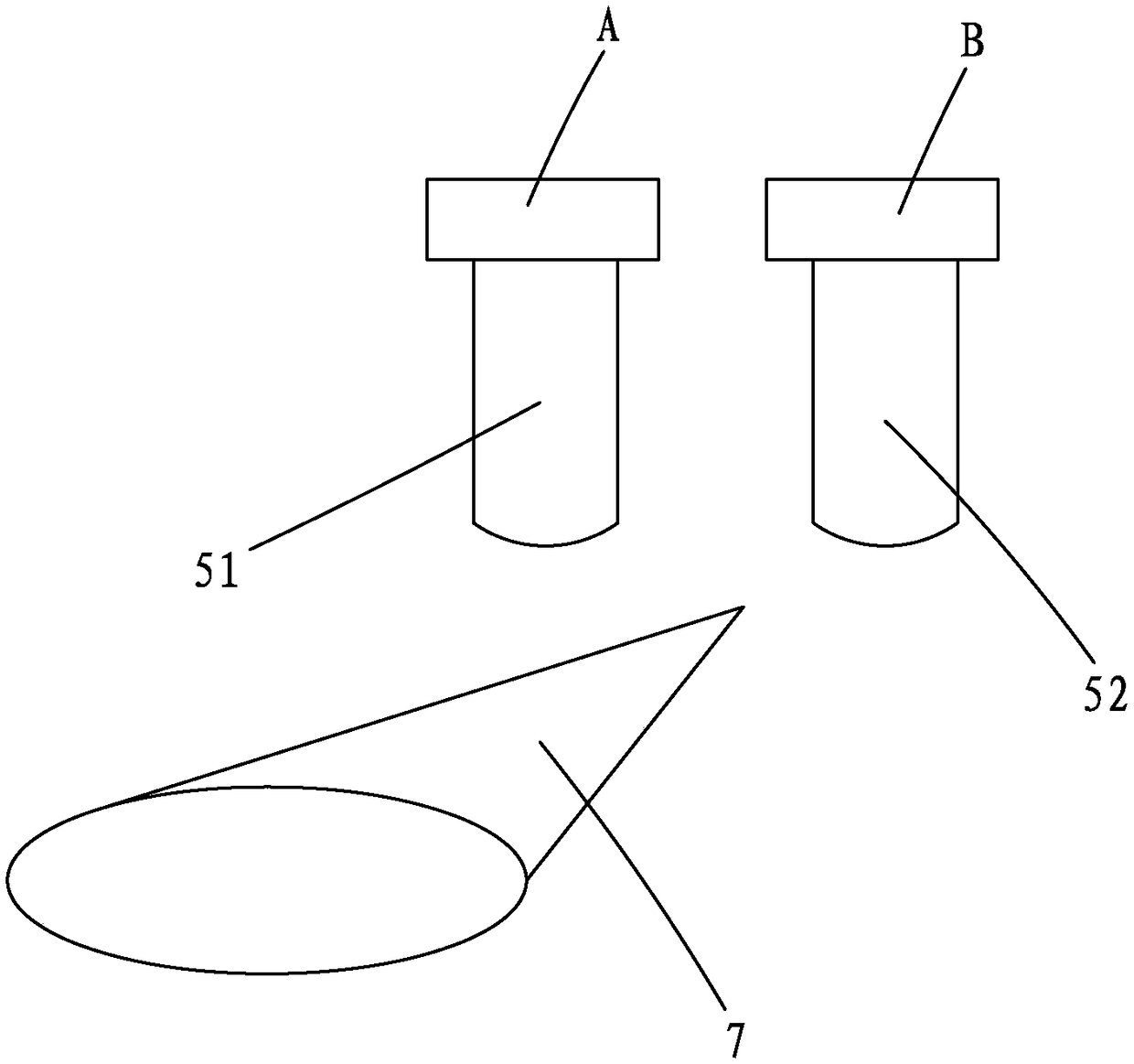

[0028] Please refer to Figure 1 to Figure 3As shown, an optical pulse sensor 100 of a smart water meter in the present invention, the optical pulse sensor 100 includes a sensor housing 1, an MCU 2, a circuit board 3, a light emitting diode 4, and two optical environment brightness sensing elements A, B , two light guide columns 51, 52 and a current limiting resistor unit 6; the MCU2 and the circuit board 3 are all located inside the sensor housing 1, the MCU2 is fixed on the circuit board 3, specifically the MCU2 can be fixed On the upper surface of the circuit board 3; the MCU2 is connected to the positive pole of the light-emitting diode 4 through the current-limiting resistor unit 6, and the negative pole of the light-emitting diode 4 is connected to the MCU2. In specific implementation, it can be The light-emitting brightness of the light-emitting diode 4 is controlled by the current-limiting resistor unit 6, and the larger the resistance value, the darker the light-emitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com