Aluminum electrolysis serial head groove emergency device and emergency method thereof

An emergency device and technology for aluminum electrolysis, applied in the field of aluminum electrolysis equipment, can solve the problems of difficulty in emergency treatment and cannot be fully applied to the electrolytic cell at the input end, and achieve the effects of convenient and fast crimping, easy emergency treatment, and easy assembly and disassembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

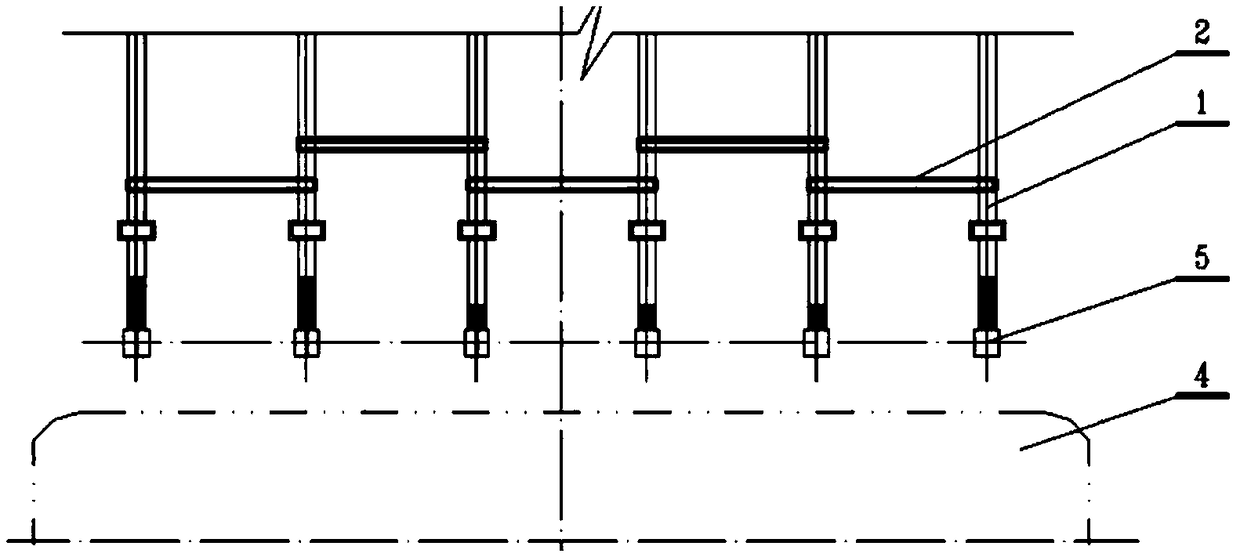

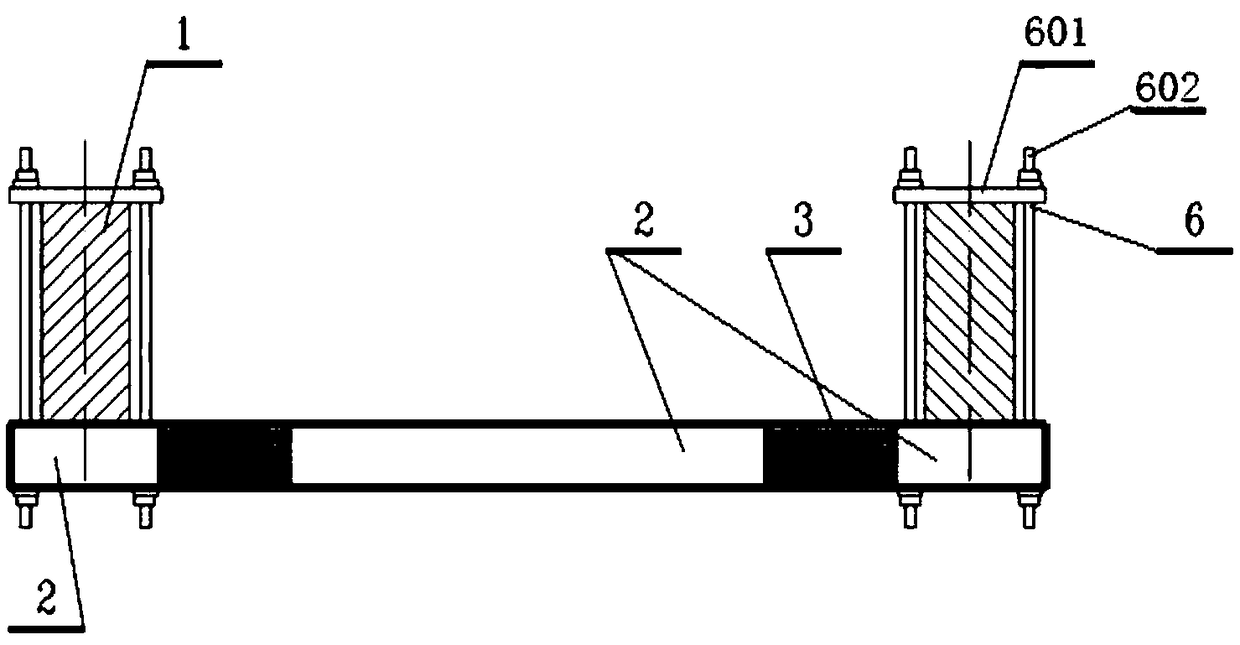

[0023] Embodiment 1: see attached Figure 1-Figure 2 , an aluminum electrolytic series head slot emergency device, the head slot emergency device includes conductors 2 or three conductors 2 connected to each other through soft connections 3 of copper soft strips or aluminum soft strips, and the two connection ends of the head slot emergency device are respectively Two adjacent aisle busbars 1 connected to the electrolytic cell 4, each aisle busbar 1 is connected to the corresponding column busbar 5, and the middle section of the three conductors can be supported by a support frame.

[0024] Conductor 2 is made of aluminum or copper

[0025] The end conductor 2 of the head groove emergency device is connected and compressed with the aisle bus 1 through a crimping device 6 .

[0026] The crimping device 6 includes two pressing plates 601 and bolts 602. Between the two pressing plates 601, the end conductor 2 and the aisle bus 1 are pressed together and locked by the bolts 602. ...

Embodiment 2

[0030] Embodiment 2: see attached Figure 1-Figure 2 , when the connecting plate connecting the aisle busbar of the electrolyzer at the power inlet end of each work area to the upright busbar is faulty and cannot pass through, or the upright busbar has a condition and cannot pass through, this part of the current is transferred to the aisle busbar 1 through the emergency device of the head slot , lead to the aisle bus 1 of other groups and then enter the electrolyzer 4 at the power inlet end through the corresponding column bus, so as to continue to maintain the production of the electrolyzer.

[0031] The invention is used in the accident state of the head tank of the electrolysis series, such as the explosion of the short circuit, the emergency device of the head tank is used as a bypass device to temporarily pass the flow, so as to avoid the shutdown of the electrolysis series. When an accident occurs at the short-circuit port of the electrolyzer at the power inlet end of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com