Application of magnetic ionic liquid as magnetic seal lubricating material

A magnetic ionic liquid and lubricating material technology, applied in the direction of magnetic liquid, lubricating composition, base material, etc., can solve the problems of application conditions and service life limitations, large specific surface area of nanoparticles, thermodynamic instability, etc., to avoid environmental pollution and resource waste, stable physical and chemical properties, and strong magnetic response performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

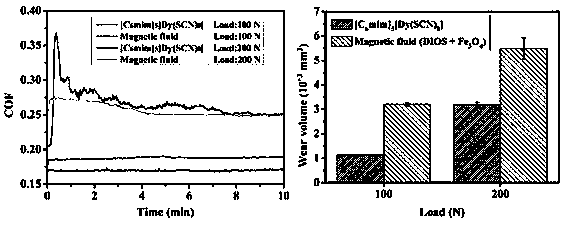

[0022] A kind of magnetic ionic liquid, its concrete composition is [C 6 mim] 5 [Dy(SCN) 8 ]. Under the action of a magnetic field, the magnetic ionic liquid was immobilized in the frictional contact area and combined with a commercially available magnetic lubricant (DIOS+Fe 3 o 4 , Fe 3 o 4 wt% is 20%), and the tribological properties of magnetic ionic liquids and magnetic lubricants under vertical loads of 100N and 200N at 25°C were investigated respectively. Friction conditions: 316 steel balls with a diameter of 4mm paired with 304 steel sheets for the friction pair; the single stroke is 5mm; the linear speed is 10mm / S; the test temperature is 25°C; For specific friction results, see figure 1 .

[0023] Depend on figure 1 It can be seen that under the condition of room temperature (25°C) of magnetic ionic liquid, the friction curve is stable, the average friction coefficient decreases by 40% and 32% compared with the magnetic lubricant when the load is 100N and 2...

Embodiment 2

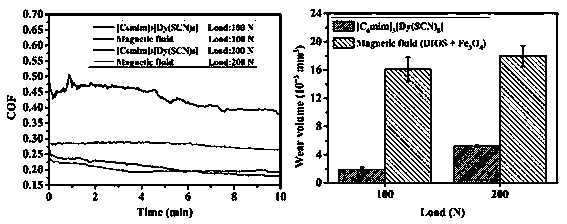

[0025] A kind of magnetic ionic liquid, its concrete composition is [C 6 mim] 5 [Dy(SCN) 8 ]. Under the action of a magnetic field, the magnetic ionic liquid was immobilized in the frictional contact area and combined with a commercially available magnetic lubricant (DIOS+Fe 3 o 4 , Fe 3 o 4 The tribological properties of magnetic ionic liquids and magnetic lubricants under vertical loads of 100N and 200N at 150°C were compared. Friction conditions: 316 steel balls with a diameter of 4mm paired with 304 steel sheets for the friction pair; single stroke is 5mm; For specific friction results, see figure 2 .

[0026] Depend on figure 2 It can be seen that under the condition of high temperature (150°C) of magnetic ionic liquid, the friction coefficient is significantly lower than that of magnetic lubricant at loads of 100N and 200N, and changes steadily with time. When the load is 100N and 200N, the wear volume under magnetic ionic liquid lubrication is reduced by 87%...

Embodiment 3

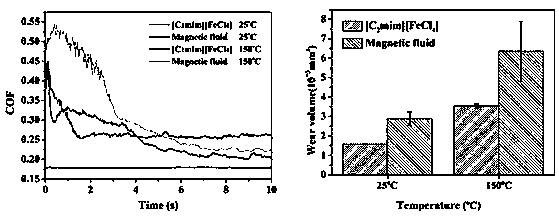

[0028] A kind of magnetic ionic liquid, its concrete composition is [C 2 mim] [FeCl 4 ]. Under the action of a magnetic field, the magnetic ionic liquid was immobilized in the frictional contact area and combined with a commercially available magnetic lubricant (DIOS+Fe 3 o 4 , Fe 3 o 4 wt% is 20%) for comparison. The tribological properties of the magnetic ionic liquid and the magnetic lubricant at 25°C and 150°C were investigated respectively under the condition of a load of 100N. Friction conditions: Silicon nitride steel balls with a diameter of 4mm are used to pair with 304 steel sheets for the friction pair; the single stroke is 5mm; the linear speed is 10mm / S; the type and size of the magnetic field: a magnetic field generated by a magnet, 200mT. For specific friction results, see image 3 .

[0029] Depend on image 3 It can be seen that after changing the frictional pair to silicon nitride and steel sheet, the friction coefficient of magnetic ionic liquid is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com