Preparation method of cationic nanometer cellulose containing lignin

A nano-cellulose, cationization technology, applied in the field of preparation of cationized nano-cellulose, to achieve efficient and clean production, low equipment requirements, avoiding environmental pollution and occupying land

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Preparation of Cationic Nanocellulose Using Tobacco Stem as Raw Material

[0034] The tobacco rods were peeled and crushed, and the raw material analysis is shown in Table 1. Mix the tobacco rod powder, 2,3-epoxypropyltrimethylammonium chloride, and KOH into DMAC, wherein the amount of 2,3-epoxypropyltrimethylammonium chloride is 1% of the mass of the tobacco rod powder. times, the dosage of KOH is 0.5% of the mass of the tobacco rod powder, and the dosage of DMAC is 20 times of the mass of the tobacco rod powder. Put the reaction solution into the ultrasonic microwave chemical reactor, set the microwave at 2000MHz / 1000W, the ultrasonic frequency at 30KHz / 50W, react at 40°C for 5h, filter the obtained liquid, and recover the filtrate containing DMAC for recycling, and wash the filter residue with deionized water After washing 5 times, cationized nanocellulose can be obtained.

[0035] Verification 1

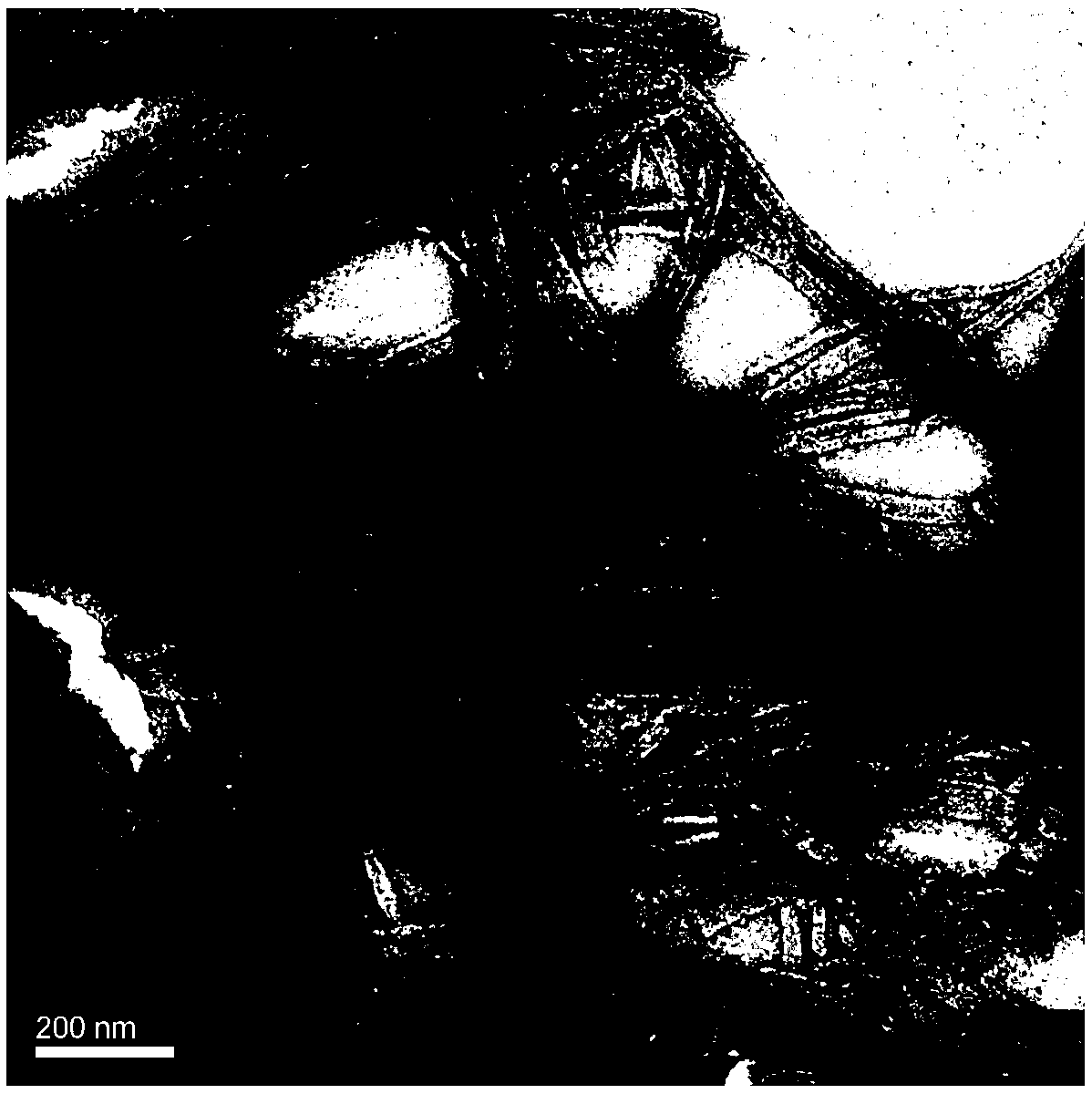

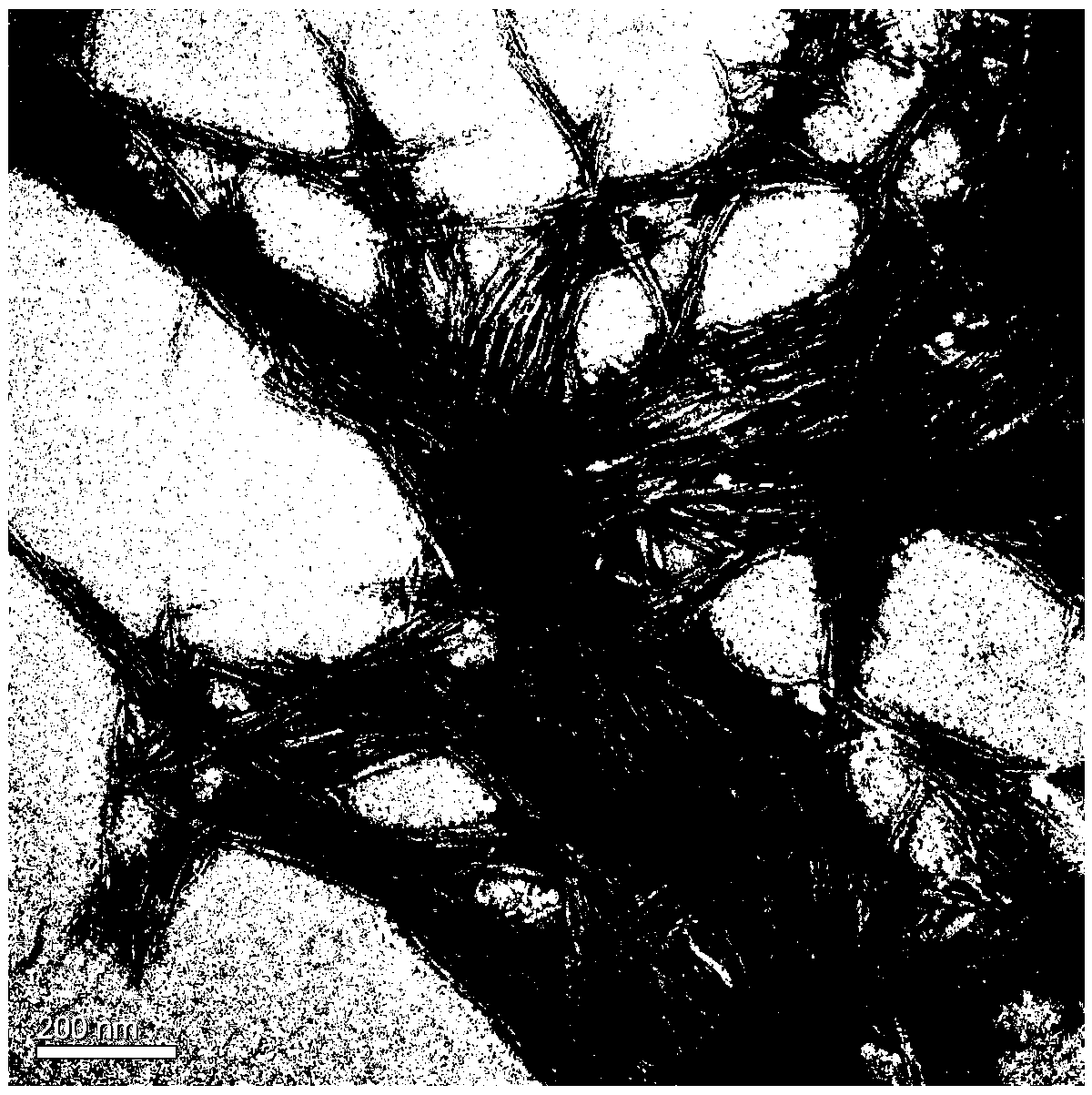

[0036] It can be seen that embodiment 1 has successfully obtained ...

Embodiment 2

[0038] Preparation of Cationic Nanocellulose from Corn Bracts

[0039] The maize husks were crushed, and the raw material analysis is shown in Table 3. Mix corn husk powder, tetradecyltrimethylammonium bromide, and KOH into DMF, wherein the amount of tetradecyltrimethylammonium bromide is 10 times the mass of corn bract powder, and the amount of KOH is 10 times that of corn bract powder. 3% of the mass of the bract powder, and the amount of DMF is 200 times of the mass of the corn bract powder. Put the reaction solution into the ultrasonic microwave chemical reactor, set the microwave at 2400MHz / 800W, the ultrasonic frequency at 40KHz / 50W, react at 40°C for 1h, filter the obtained liquid, recover the filtrate containing DMF and recycle it, and wash the filter residue with deionized water After washing 5 times, cationized nanocellulose can be obtained.

[0040] Verification 2

[0041] It can be seen that embodiment 2 has successfully obtained nanocellulose fibrils with a dia...

Embodiment 3

[0044] Preparation of Cationic Nanocellulose Using Asparagus Asparagus as Raw Material

[0045] The asparagus is pulverized, and the raw material analysis is shown in Table 5. Take asparagus powder, 3-chloro-2-hydroxypropyltrimethylammonium chloride and NaOH and mix them into DMSO, wherein the dosage of 3-chloro-2-hydroxypropyltrimethylammonium chloride is 5 times of the mass of the powder, the amount of NaOH is 1% of the mass of the Asparagus powder, and the consumption of DMSO is 100 times of the mass of the Asparagus powder. Put the reaction solution into the ultrasonic microwave chemical reactor, set the microwave at 2300MHz / 1000W, the ultrasonic frequency at 35KHz / 50W, react at 65°C for 4h, filter the obtained liquid, recover the filtrate containing DMSO and recycle it, and wash the filter residue with deionized water After washing 5 times, cationized nanocellulose with a diameter of about 40 nm can be obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com