Counter slot type aerobic compost fermentation process and structure thereof

An aerobic composting and slotting technology, which is applied to organic fertilizers, fertilization devices, excretion of fertilizers, etc., can solve problems such as dust and corrosion of facilities, and achieve the effects of less failure rate, low operation and maintenance costs, and strong operational flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

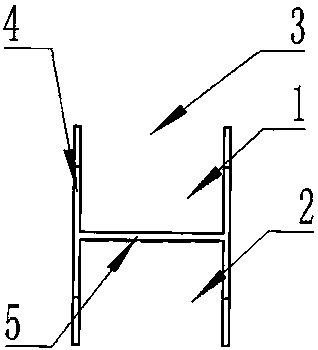

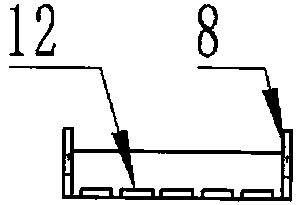

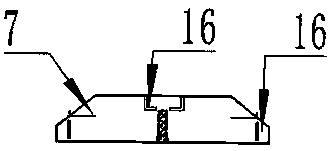

[0019] Embodiments of the present invention are described in detail below, examples of which are shown in the drawings, wherein the same or similar reference numerals designate the same or similar elements or elements having the same or similar functions throughout. The embodiments described below by referring to the figures are exemplary and are intended to explain the present invention and should not be construed as limiting the present invention.

[0020] The technical scheme is as follows for the trough type aerobic composting fermentation process:

[0021] 1. Mixing pretreatment

[0022] According to the components and states of different fermentation raw materials, according to the quality of the main fermentation material, the auxiliary materials and other ingredients are added according to the parameter ratio and mixed uniformly through the mixer. Control parameters include Main fermentation raw material ratio: the ratio of dry manure to dung residue (or biogas resi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com