A kind of interface agent for steel structure inner wall with anti-corrosion coating

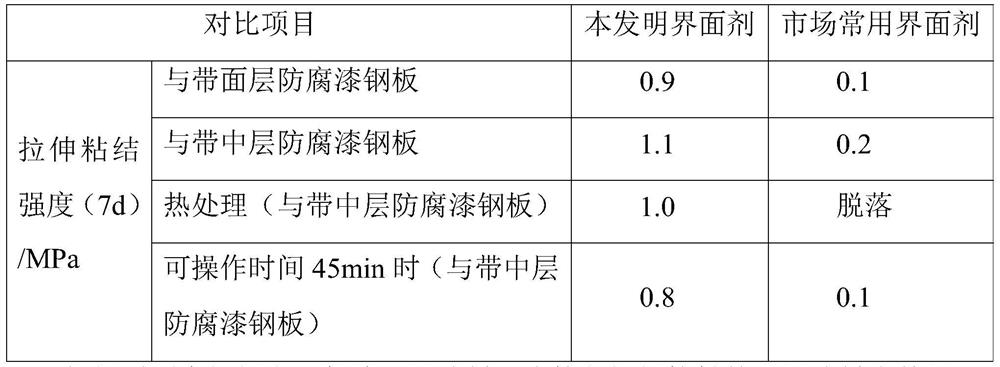

An anti-corrosion coating and interface agent technology, applied in the field of building materials, can solve the problems of high mechanical bite force and chemical bonding force, lack of interface agent, shedding, etc., to improve construction performance and water retention performance, speed up strength growth, good The effect of adhesive properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] An interface agent for steel structure interior walls with an anti-corrosion coating, composed of 42.5 grade ordinary Portland cement 400, medium sand 600, ethylene vinyl acetate latex powder 70, and hydroxypropyl methyl cellulose ether in parts by weight 1.0 and 0.05 parts of triethanolamine. Add 145 parts by weight of water and stir evenly. After standard curing for 7 days, the tensile bonding strength of the interface agent provided in this example and the steel plate with anti-corrosion coating is 1.1 MPa, and the tensile bonding strength with the concrete slab is 1.6 MPa, the folding ratio is 2.1. This formula is suitable for use during construction in spring and autumn.

Embodiment 2

[0034] An interface agent for steel structure interior walls with an anti-corrosion coating, in parts by weight, consists of 42.5 grade ordinary Portland cement 500, medium sand 500, acrylate latex powder 80, hydroxyethyl methyl cellulose ether 1.5 , prepared from 0.15 parts of triethanolamine. Add 155 parts by weight of water and stir evenly. After 7 days of standard curing, the tensile bonding strength of the interface agent provided in this example and the steel plate with anti-corrosion coating is 1.0 MPa, and the tensile bonding strength with the concrete slab is 1.6 MPa, the folding ratio is 2.0. This formula is suitable for use during high temperature construction in summer.

Embodiment 3

[0036] An interface agent for steel structure interior walls with an anti-corrosion coating, in parts by weight, consists of 42.5 grade ordinary Portland cement 600, medium sand 400, styrene-butadiene latex powder 50, hydroxypropyl methyl cellulose ether 2.0 , prepared from 0.25 parts of triethanolamine. Add 150 parts by weight of water and stir evenly. After 7 days of standard curing, the tensile bond strength between the interface agent provided in this example and the steel plate with anti-corrosion coating is 0.7 MPa, and the tensile bond strength with the concrete slab is 1.2 MPa. MPa, the folding ratio is 2.3. This formula is suitable for use during low temperature construction in winter.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com