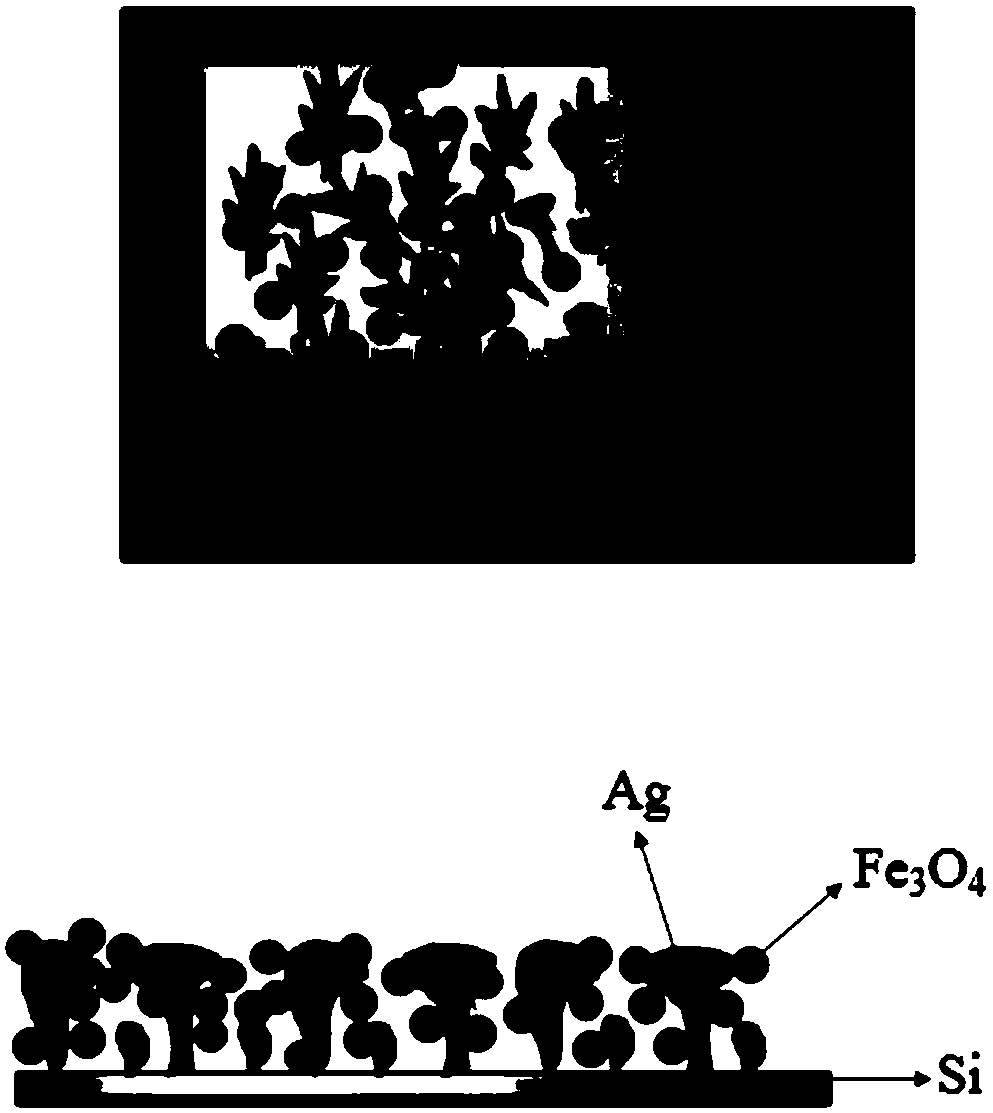

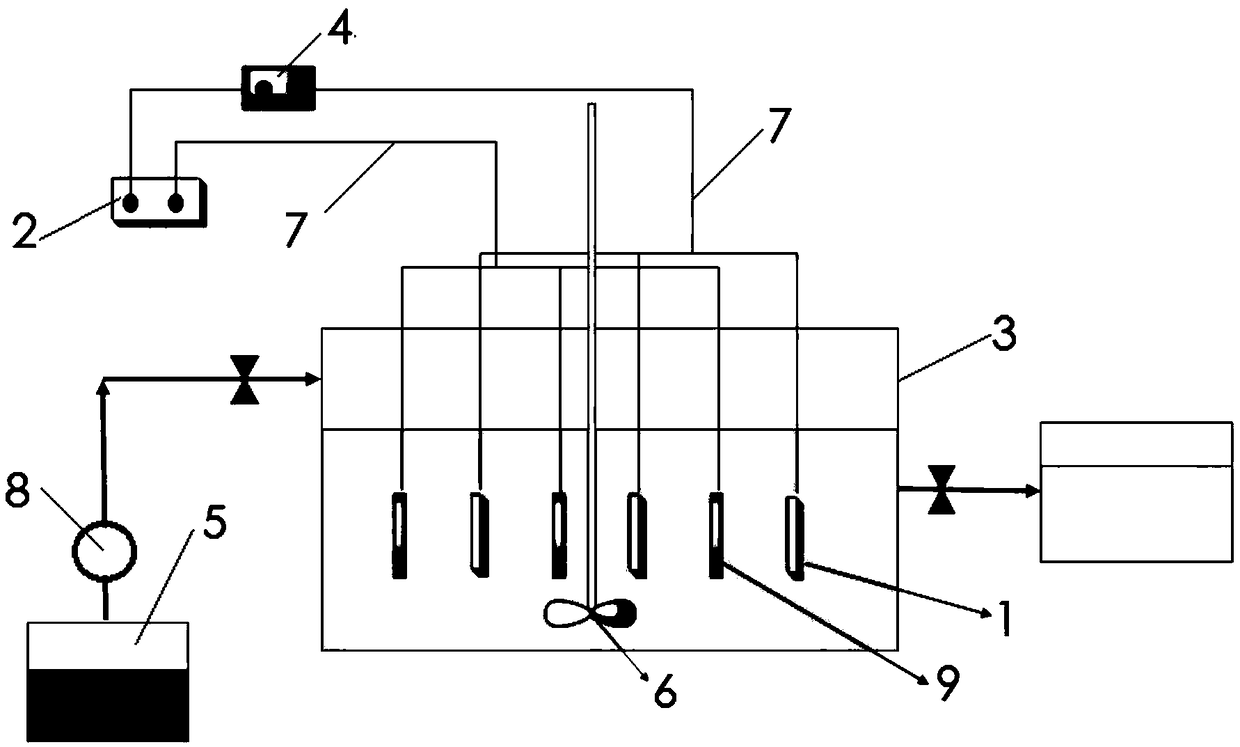

A Fe3O4/Ag@Si three-dimensional composite electrode, a preparation method thereof and an advanced oxidation integrated technical system

A three-dimensional composite and electrode technology, applied in the field of advanced oxidation integrated technology systems, can solve the problems of loss of catalysis, inability to reuse, secondary pollution, etc., and achieve the effect of promoting degradation, reducing iron sludge, and efficient degradation of pollutants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 1.1Fe 3 o 4 / Ag@Si electrode synthesis method, the steps are:

[0045] (1) Put the P-type boron-doped single crystal silicon into the HF solution and react for 5 minutes, and use the HF solution to remove the SiO on the surface of the P-type boron-doped single crystal silicon 2 The oxide layer is then taken out, rinsed with deionized water and then dried in a vacuum oven to obtain a treated silicon chip; the concentration of the HF solution for removing the oxide layer is 2.4mol / L.

[0046] (2) Add 100ml of deionized water to the polytetrafluoroethylene container, then add the HF solution and AgNO 3 Solid, to completely dissolve the silver nitrate, put the silicon chip treated in step 1 into the solution, that is, directly put the P-type boron-doped single crystal silicon into the solution by chemical method to make it react, and then wash it with deionized water Then put it into a drying oven to dry, and obtain P-type boron-doped single crystal silicon grown with el...

Embodiment 2

[0055] 2.1Fe 3 o 4 / Ag@Si electrode synthesis method, the steps are:

[0056] (1) Put the P-type boron-doped single crystal silicon into the HF solution and react for 5 minutes, and use the HF solution to remove the SiO on the surface of the P-type boron-doped single crystal silicon 2 The oxide layer is then taken out, rinsed with deionized water and then dried in a vacuum oven to obtain a treated silicon chip; the concentration of the HF solution for removing the oxide layer is 4.8mol / L.

[0057] (2) Add 100ml of deionized water to the polytetrafluoroethylene container, then add the HF solution and AgNO 3 Solid, to completely dissolve the silver nitrate, put the silicon chip treated in step 1 into the solution, that is, directly put the P-type boron-doped single crystal silicon into the solution by chemical method to make it react, and then wash it with deionized water Then put it into a drying oven to dry, and obtain P-type boron-doped single crystal silicon grown with el...

Embodiment 3

[0065] 3.1 New Fe 3 o 4 / Ag@Si electrode synthesis method

[0066] (1) Put the P-type boron-doped single crystal silicon into the HF solution and react for 5 minutes, and use the HF solution to remove the SiO on the surface of the P-type boron-doped single crystal silicon 2 The oxide layer is then taken out, rinsed with deionized water and then dried in a vacuum oven to obtain a treated silicon chip; the concentration of the HF solution for removing the oxide layer is 9.6mol / L.

[0067] (2) Add 100ml of deionized water to the polytetrafluoroethylene container, then add the HF solution and AgNO 3 Solid, to completely dissolve the silver nitrate, put the silicon chip treated in step 1 into the solution, that is, directly put the P-type boron-doped single crystal silicon into the solution by chemical method to make it react, and then wash it with deionized water Then put it into a drying oven to dry, and obtain P-type boron-doped single crystal silicon grown with elemental sil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com