Ammonia-nitrogen wastewater treatment system and ammonia-nitrogen wastewater treatment method

An ammonia nitrogen wastewater treatment system technology, which is applied in adsorption water/sewage treatment, water/sludge/sewage treatment, separation methods, etc., can solve the problems of large area of biological treatment, increased treatment cost, and unqualified water production. , to achieve the effect of low operating cost, convenient operation and small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

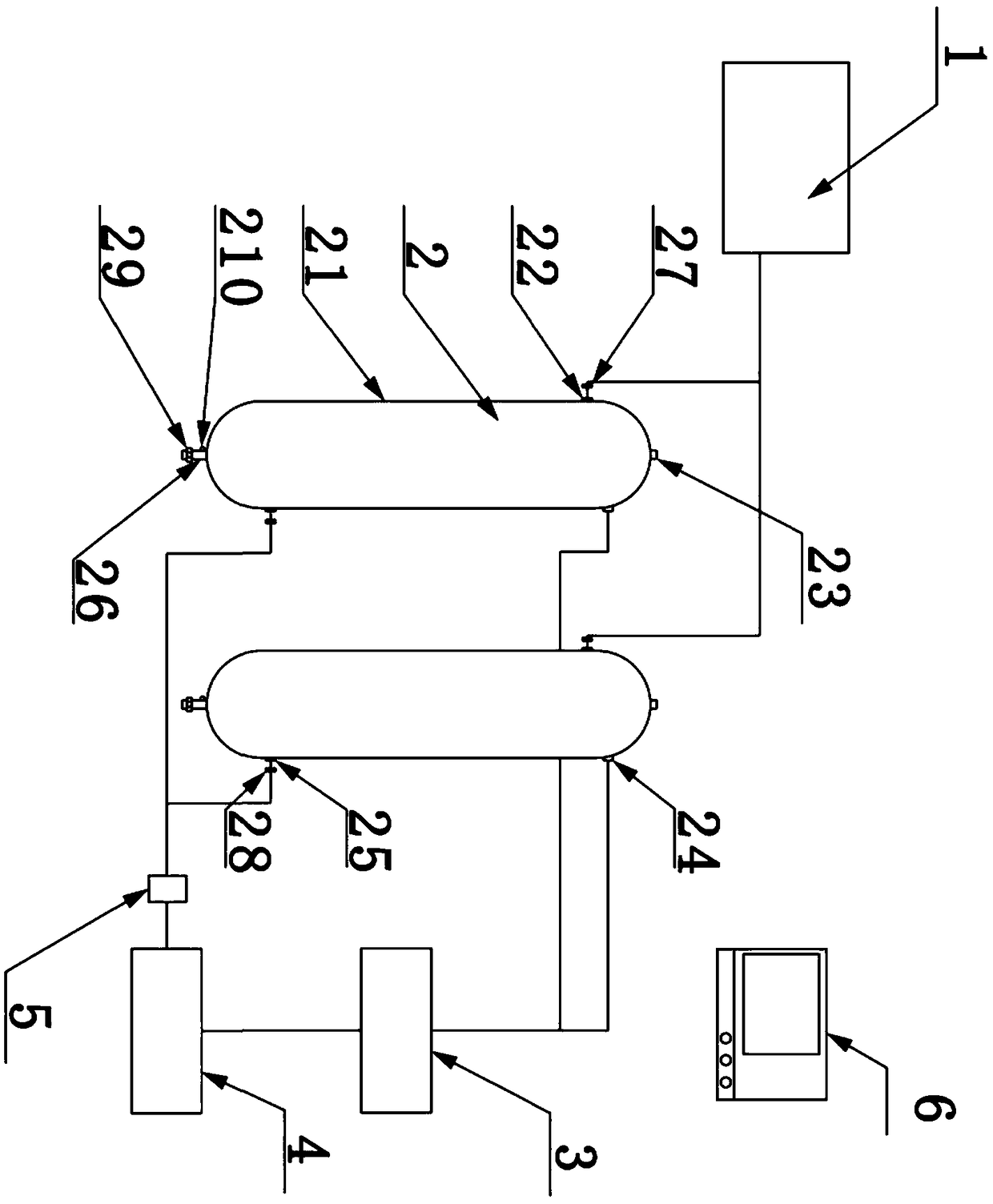

[0025] In the embodiment of the present invention, such as figure 1 As shown, an ammonia nitrogen wastewater treatment system is provided, including an ammonia nitrogen wastewater storage tank 1, an adsorption column group, a sodium chloride solution header 3, an electrolytic cell 4 and a control terminal 6. Wherein, the adsorption column group includes two adsorption columns 2 arranged in parallel, their structures are identical, and they are fixed on the same horizontal plane by brackets.

[0026] A single adsorption column 2 includes a shell 21, which is provided with an ammonia nitrogen waste water inlet 22, a treatment liquid outlet 26, a regeneration liquid inlet 25, a regeneration liquid outlet 24, and a gas discharge port 23, and is filled with a solid adsorbent inside. It is an adsorbent with good adsorption performance for ammon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com