Heavy-duty electric driven all-wheel steering and all-wheel driving unmanned framework transport vehicle

An all-wheel drive, electric drive technology, applied in motor vehicles, steering mechanisms, steering rods, etc., can solve problems such as large steering resistance and wear of driving wheel tires, and achieve smooth operation, reduced running resistance, and high-precision positioning. The effect of navigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

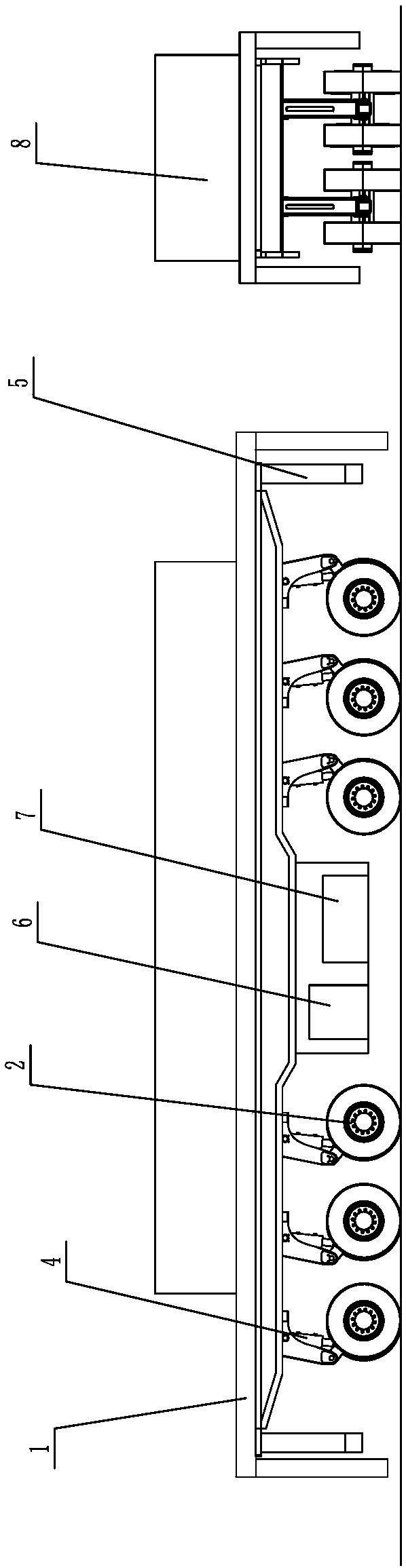

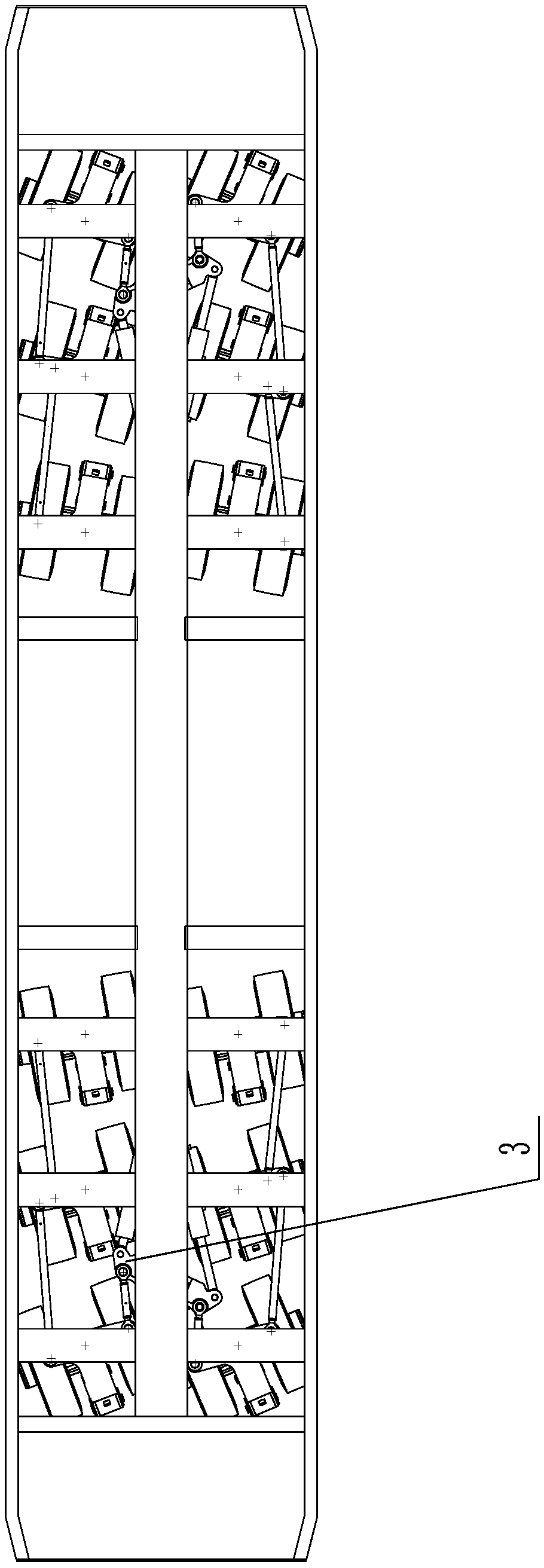

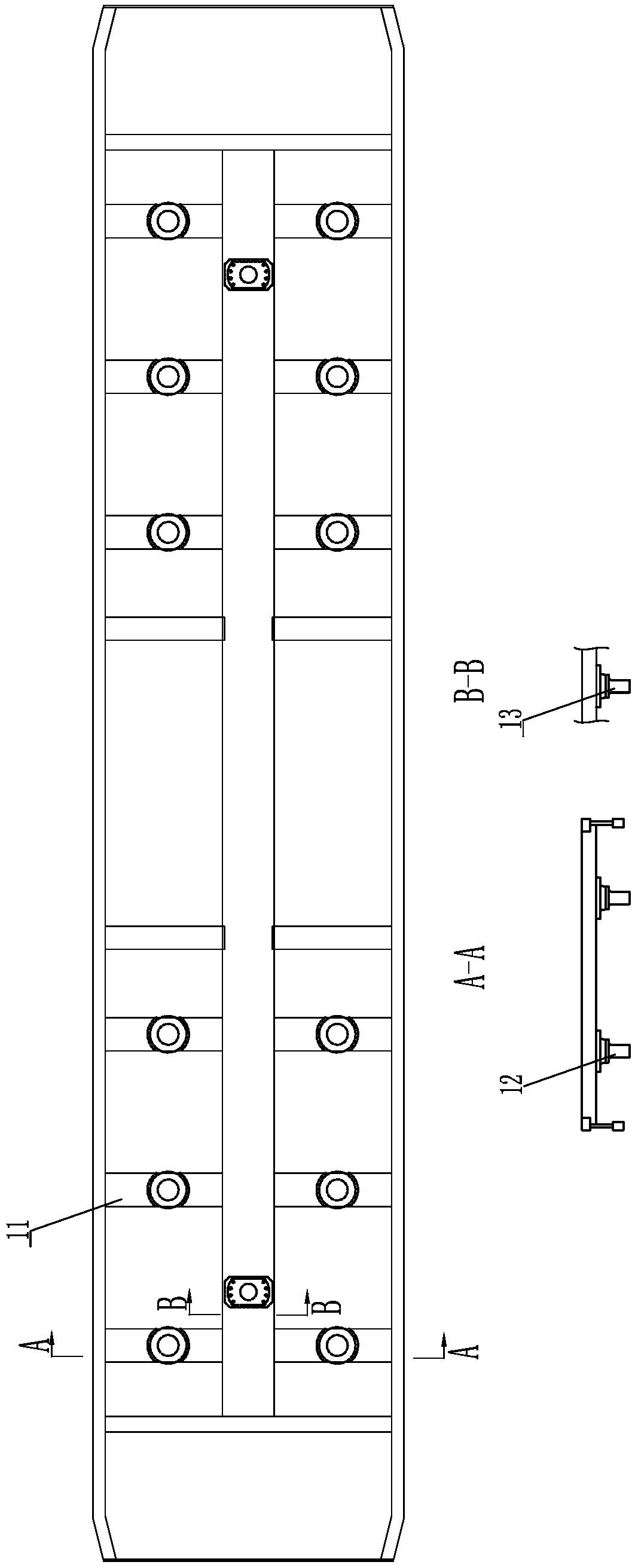

[0043] Such as Figure 1-6 As shown, the present invention provides a heavy-duty electric-driven all-wheel drive unmanned frame transport vehicle, including a frame assembly 1 for placing goods, and also includes:

[0044] Steering assembly 3 includes steering cylinder I 31, steering cylinder II 32, frame connecting plate 33, two active steering structures 38 and cylinder connecting seat 37 fixedly installed on the frame assembly 1; wherein, the frame is connected to The plate 33 is rotationally connected with the frame assembly 1, the cylinder rods and tails of the steering cylinder I31 and the steering cylinder II32 are respectively rotationally connected with the frame connecting plate 33 and the cylinder connecting seat 37, two The active steering structure 38 is respectively rotatably connected to the vehicle frame assembly 1, and is rotatably connected to both sides of the vehicle frame connecting plate 33 through the connecting rod I34;

[0045] The drive axle assembly...

Embodiment 2

[0060] Such as Figure 5 As shown, on the basis of Embodiment 1, the steering assembly 3 further includes a driven steering structure II 310 that corresponds to the two driven steering structures I 39 one by one, and the driven steering structure I 39 passes through the connecting rod III 36 It is rotationally connected with the driven steering structure II 310, and each driven steering structure II 310 is equipped with one drive axle assembly 2 and one suspension assembly 4;

[0061] Wherein, in the suspension assembly 4 corresponding to the driven steering structure II 310, the cylinder rod and tail of the suspension cylinder 41 are respectively rotationally connected with the balance arm 42 and the corresponding driven steering structure II 310 , one end of the balance arm 42 is fixed to the corresponding lower axle housing 23 through the baffle plate 43, and the other end is rotationally connected to the corresponding driven steering structure II 310;

[0062] The driven ...

Embodiment 3

[0066] Such as figure 1 As shown, on the basis of Embodiment 1 or Embodiment 2, the transport vehicle also includes a power cabin 6 for providing power to the drive axle assembly 2 and a power cabin 6, the steering assembly 3, The drive axle assembly 2 and the electrical equipment 7 for synchronous control of the suspension assembly 4 ; the power cabin 6 and the electrical equipment 7 are fixedly installed on the vehicle frame assembly 1 .

[0067] Further, the electrical equipment 7 is used to control the startup and shutdown of the power cabin 6, the elongation and shortening of the cylinder rods of the steering cylinder I31 and the steering cylinder II32, the wheel reducer 21 and the The starting and closing of the permanent magnet synchronous motor 25 and the elongation and shortening of the cylinder rod of the suspension cylinder 41.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com