Composite plastic sheet material for liquid food packaging

A technology for compounding plastic and liquid food, applied in the field of packaging materials, can solve the problems of instability of liquid food packaging materials, and achieve the effects of inhibiting the tendency of oxidation reaction, low production cost, and strong process controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

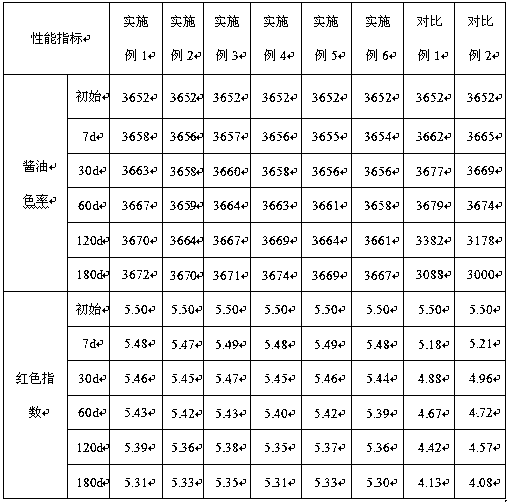

Examples

Embodiment 1

[0027] The composite plastic sheet structure is as follows:

[0028] The composite plastic sheet is made of the uppermost layer, the middle layer and the lowermost layer through hot pressing.

[0029] The uppermost layer is the base layer of biaxially oriented polypropylene film, and the stretching ratio is 4 times;

[0030] The middle layer is a polyvinylidene chloride barrier layer, which is composed of a polyvinylidene chloride layer and a black inner backing film with high-efficiency shading; the black inner backing film with high-efficiency shading is polyethylene terephthalate shading Black film;

[0031] The bottom layer is a low-density polyethylene heat-sealing layer, which is formed by dispersing microcapsules of chitosan-wrapped L-ascorbic acid in low-density polyethylene; in the microcapsules of chitosan-wrapped L-ascorbic acid, 19 parts by weight of chitosan , 81 parts by weight of L-ascorbic acid. The chitosan-wrapped microcapsules of L-ascorbic acid are dispe...

Embodiment 2

[0040] The composite plastic sheet structure is as follows:

[0041] The composite plastic sheet is made of the uppermost layer, the middle layer and the lowermost layer through hot pressing.

[0042] The uppermost layer is the base layer of biaxially oriented polypropylene film, and the stretching ratio is 3 times;

[0043] The middle layer is a polyvinylidene chloride barrier layer, which is composed of a polyvinylidene chloride layer and a black inner backing film with high-efficiency light-shielding; the black inner backing film with high-efficiency light-shielding is polyethylene terephthalate light-shielding Black film;

[0044] The bottom layer is a low-density polyethylene heat-sealing layer, which is formed by dispersing microcapsules of chitosan-wrapped L-ascorbic acid in low-density polyethylene; in the microcapsules of chitosan-wrapped L-ascorbic acid, 15 parts by weight of chitosan , 85 parts by weight of L-ascorbic acid. The chitosan-wrapped microcapsules of L-a...

Embodiment 3

[0053] The composite plastic sheet structure is as follows:

[0054] The composite plastic sheet is made of the uppermost layer, the middle layer and the lowermost layer through hot pressing.

[0055] The uppermost layer is the base layer of biaxially oriented polypropylene film, and the stretching ratio is 6 times;

[0056] The middle layer is a polyvinylidene chloride barrier layer, which is composed of a polyvinylidene chloride layer and a black inner backing film with high-efficiency light-shielding; the black inner backing film with high-efficiency light-shielding is polyethylene terephthalate light-shielding Black film;

[0057] The bottom layer is a low-density polyethylene heat-sealing layer, which is formed by dispersing microcapsules of chitosan-wrapped L-ascorbic acid in low-density polyethylene; in the microcapsules of chitosan-wrapped L-ascorbic acid, 22 parts by weight of chitosan , 78 parts by weight of L-ascorbic acid. The chitosan-wrapped microcapsules of L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com